Graphite anode and replacing method thereof

A graphite anode and anode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of dead furnace, large furnace temperature fluctuation, affecting output, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

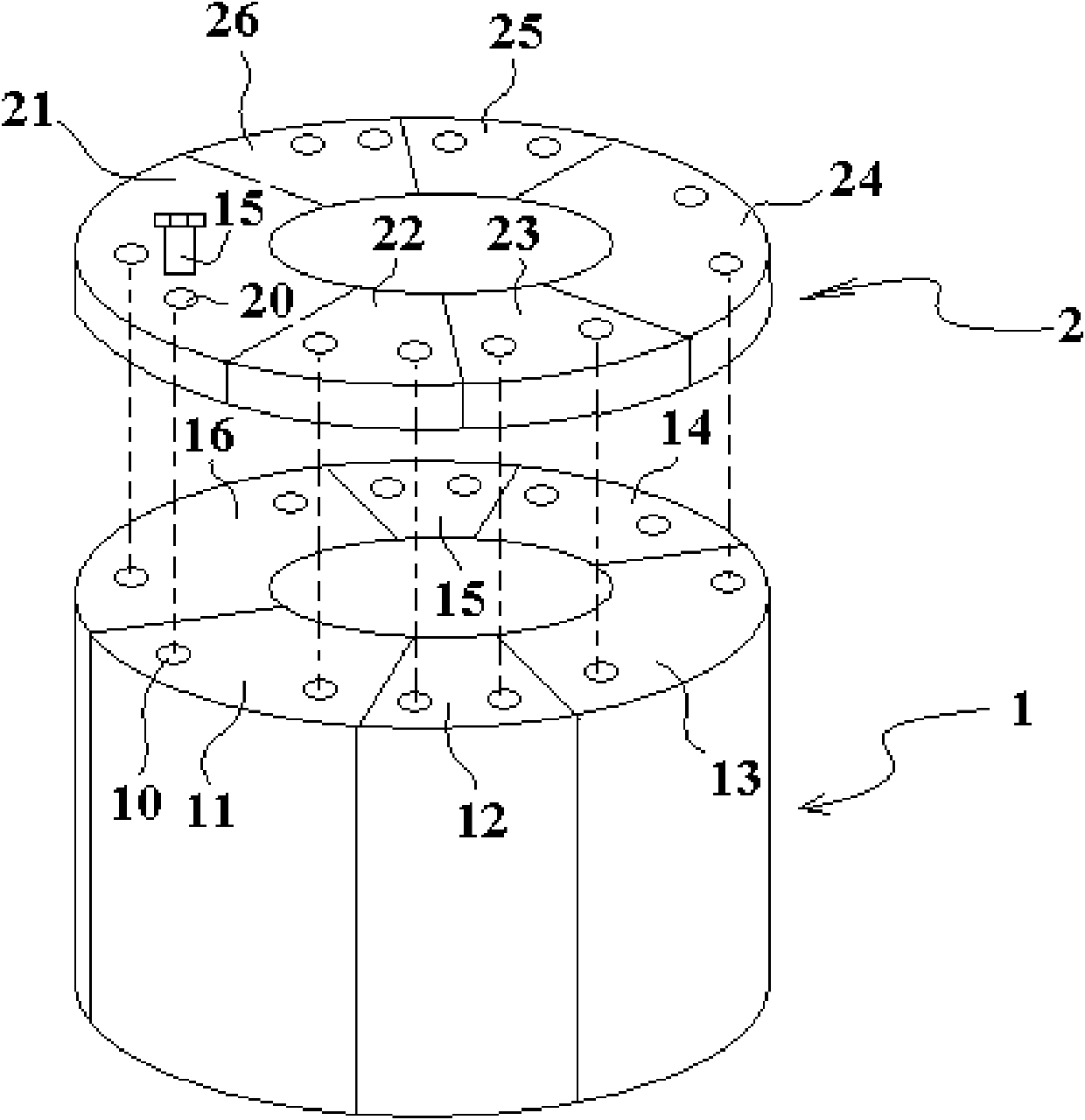

[0017] At present, the graphite anode used in the process of producing rare earth metals and alloys in a circular electrolytic cell and a rare earth oxide-fluoride molten salt system is a hollow cylinder.

[0018] In an embodiment of the present invention, the hollow cylindrical graphite anode 1 is divided into 6 anode sheets 11, 12, 13, 14, 15, and 16.

[0019] In other embodiments, the number of anode plates usually ranges from 4 to 12 plates. If the furnace body size is large, it can be divided into more pieces.

[0020] The anode sheets 11, 12, 13, 14, 15, 16 are connected in parallel, the voltage on each graphite anode sheet 11, 12, 13, 14, 15, 16 is the same, and the total electrolysis current is evenly distributed to each graphite On the anode sheets 11, 12, 13, 14, 15, 16.

[0021] In an embodiment of the present invention, two inner wire holes 10 are provided on a top surface of each graphite anode sheet 2. In other embodiments, 2-5 internal wire holes 10 are provided on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com