A heat exchange device for air purification and dust removal

A technology of gas exchange and heat exchange equipment, which is applied in waste heat treatment, lighting and heating equipment, furnaces, etc., and can solve the problems of large fluctuations in material flow field and temperature field, blockage of kiln tail smoke chamber and pipe crust, and burning of fuel coke particles. Incomplete and other problems, to achieve the effects of reducing temperature fluctuations in the furnace, increasing output per unit furnace capacity, and reducing the probability of crust blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

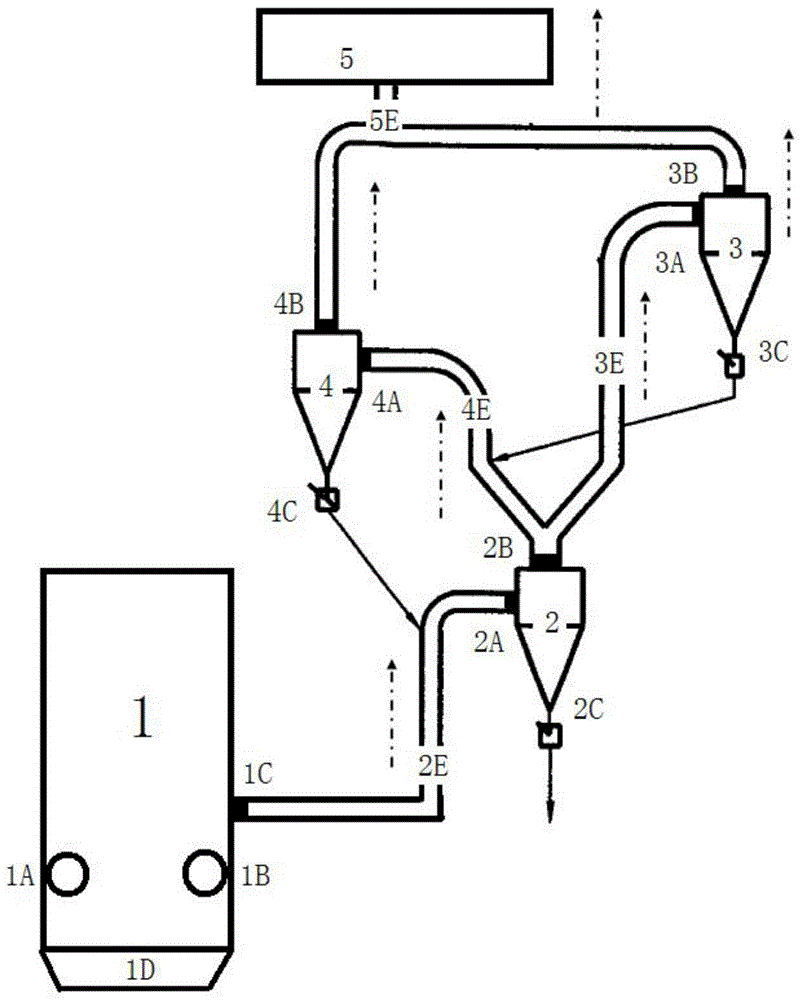

[0026] The circulation device for realizing sufficient solid-gas heat exchange of the dusty airflow of the present invention includes decomposition reaction equipment (1), first heat exchange equipment (2), second heat exchange equipment (3), and third heat exchange equipment (4) , reaction pool (5).

[0027] The decomposition reaction equipment (1) includes a feed inlet (1A), a fuel inlet (1B), an exhaust outlet (1C), and a discharge outlet (1D). The cement raw meal that has been suspended and preheated enters through the feed inlet (1A) Decomposition reaction equipment (1), the fuel is sprayed into the decomposition reaction equipment (1) through the fuel inlet (1B), the decomposition reaction equipment (1) mixes the cement raw meal that has been suspended and preheated with the fuel, and rapidly absorbs the fuel in the suspension state to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com