Double light path green light micropore processing device

A technology of microhole processing and green light, which is applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of expensive equipment, less industrial application of picosecond lasers, and high processing costs, so as to reduce thermal effects and improve processing precision degree, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

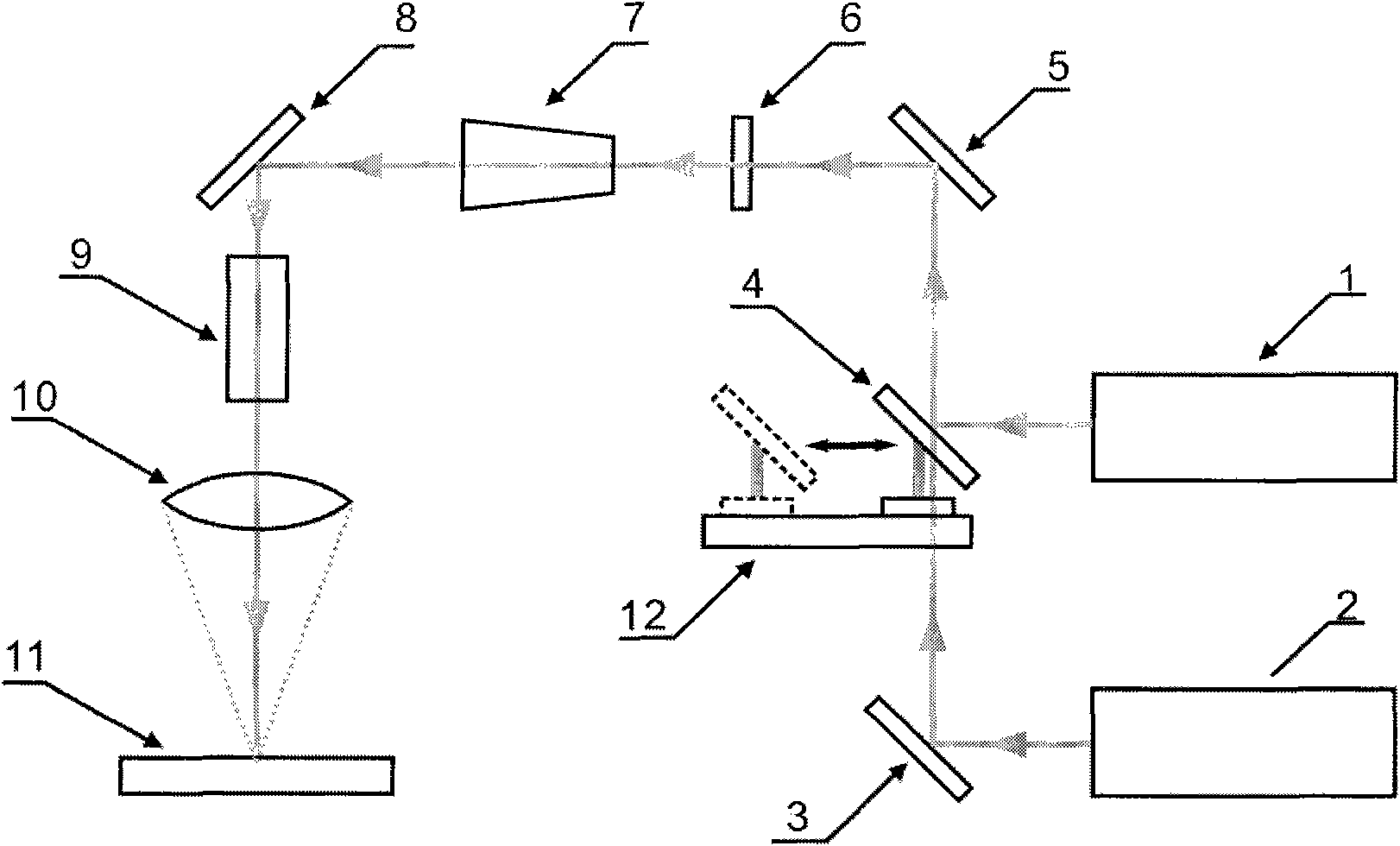

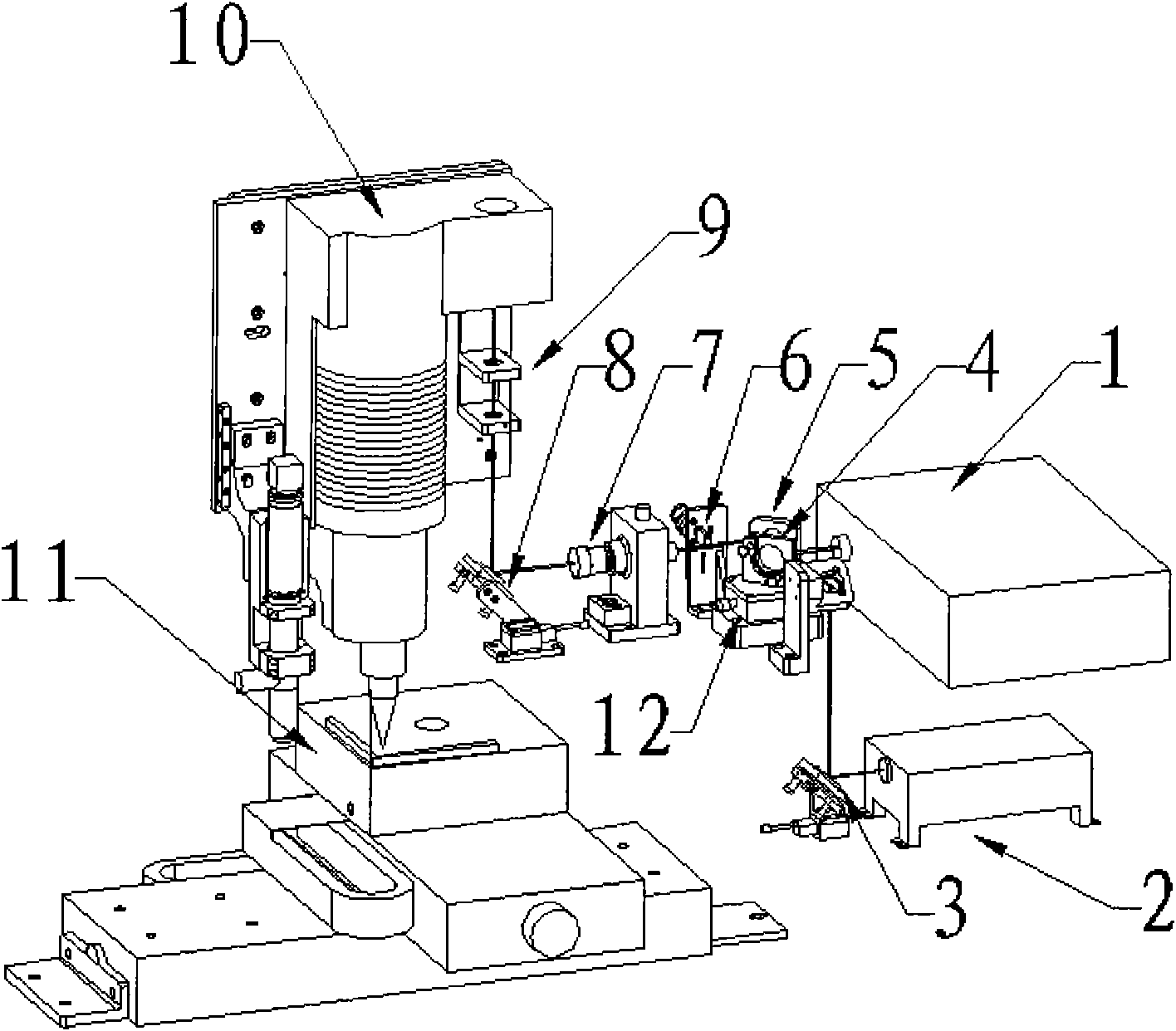

[0017] A dual optical path system is designed to integrate the optical paths of nanosecond laser (wavelength 532nm) and picosecond laser (wavelength 532nm), so that two laser beams with different pulse widths emitted from nanosecond pulse laser and picosecond pulse laser pass through After calibration, it enters the optical system to focus through the same path, so as to process micro-holes.

[0018] Such as figure 1 , figure 2 As shown, the dual-path green light microhole processing device adopts dual laser light sources, including four parts: optical path selection, optical path transmission, optical path calibration and optical focusing. The output end of the picosecond pulse laser 1 is arranged with a first reflector 4, the The reflector 4 is installed on the high-precision electric one-dimensional translation platform 12, so that the optical path selection is controlled by the high-precision electric one-dimensional translation platform 12, and the precision of the reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com