Method for impacting micro-plasticity forming with strong laser and device thereof

A microplastic, strong laser technology, applied in microstructure devices, laser welding equipment, chemical instruments and methods, etc., can solve the problems of complex process and restrict the wide application of microfabrication technology, and achieve improved sensitivity and broad industrial application prospects. , Improve the effect of surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

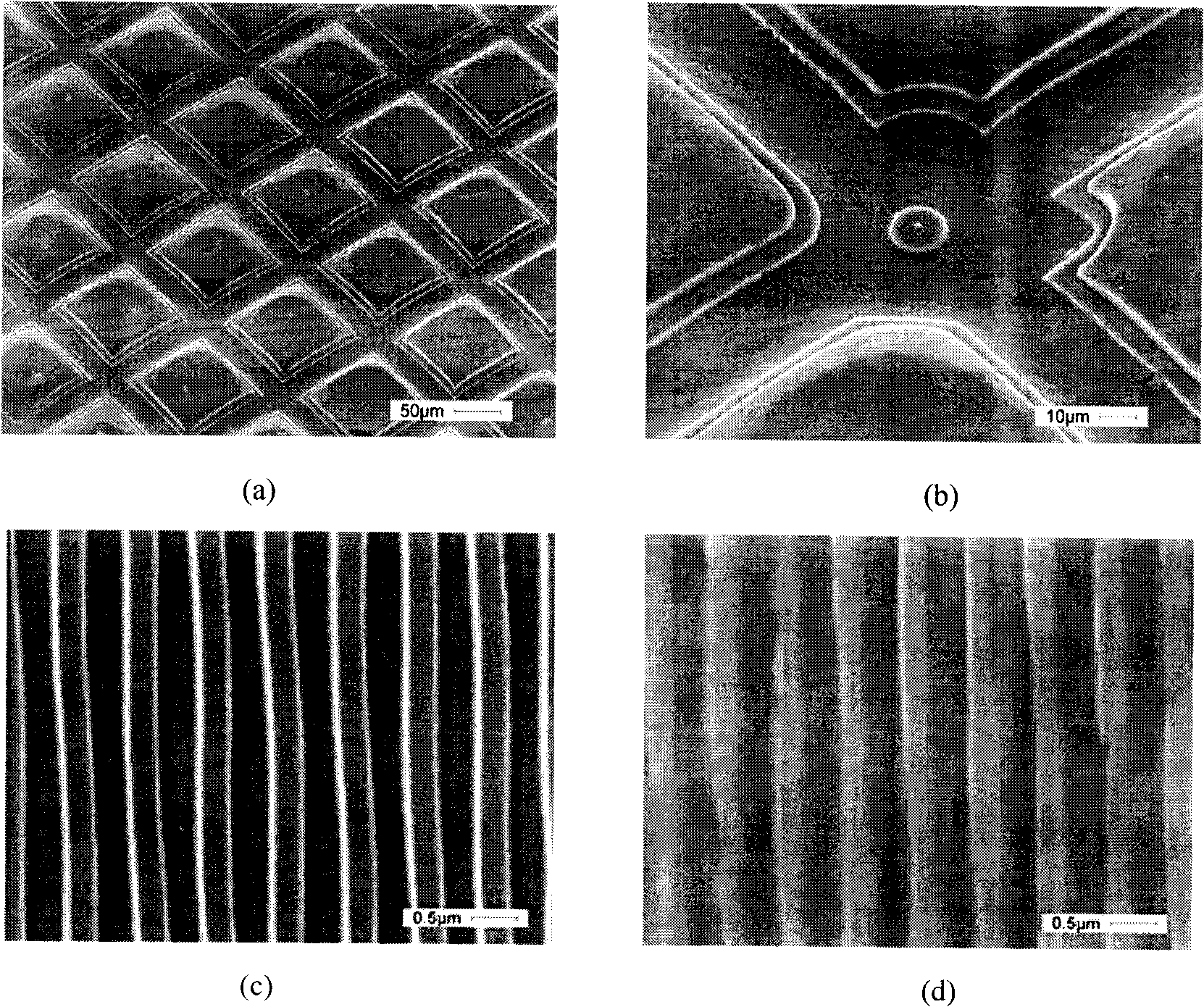

Examples

Embodiment Construction

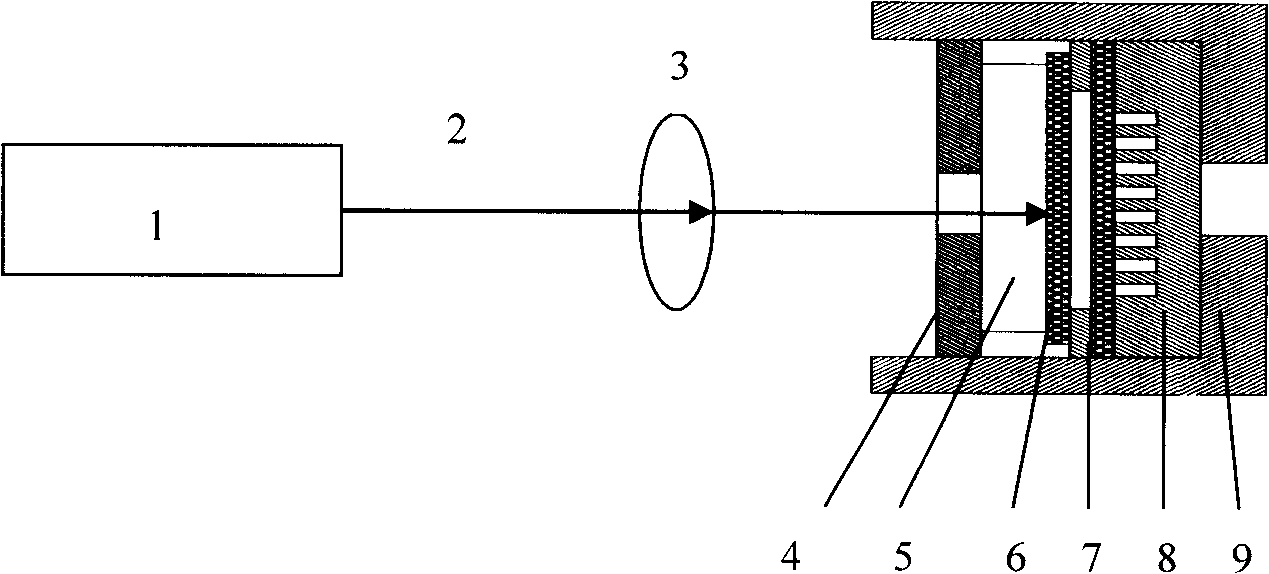

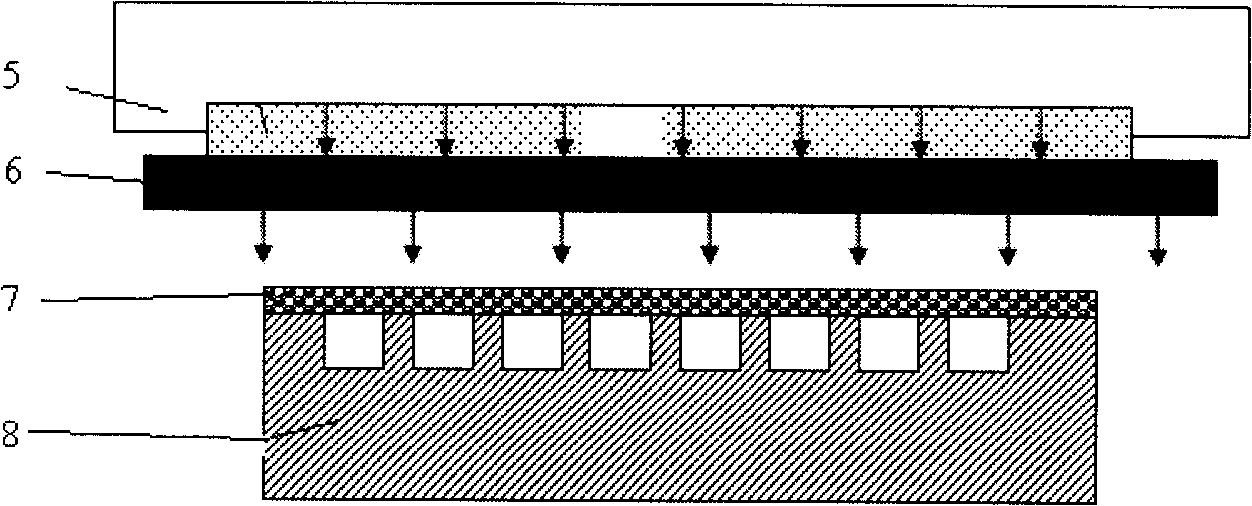

[0022] figure 1 Shown is a schematic diagram of the laser-driven flyer loading device to realize the formation of three-dimensional structures at the micro-nano scale. The details and implementation are described as follows:

[0023] The laser-driven flyer loading device to realize micro-nano scale forming three-dimensional structure consists of a laser drive system and a target clamping system. The laser drive system consists of a nanosecond pulse laser 1 and a focusing lens 3. The laser beam 2 emitted by the nanosecond pulse laser 1 is focused by the lens and directly enters the target clamping system. The target clamping system is composed of a pressure plate 4, optical glass 5, flyer 6, target material 7, template 8, and target clamper 9. The pressure plate 4 has a screw mechanism and can be screwed into the concave hole of the target clamper 9. Cavity, so that the optical glass 5 can be pressed together, and the target material 9 can be fastened in the concave cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com