Ceramic tile combining blank patterns with penetration ink patterns and production method of ceramic tile

A technology of ink patterns and production methods, which is applied in the field of architectural ceramic tiles, can solve the problems of inability to form fine and sharp textures, and achieve the effect of fine pattern textures and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

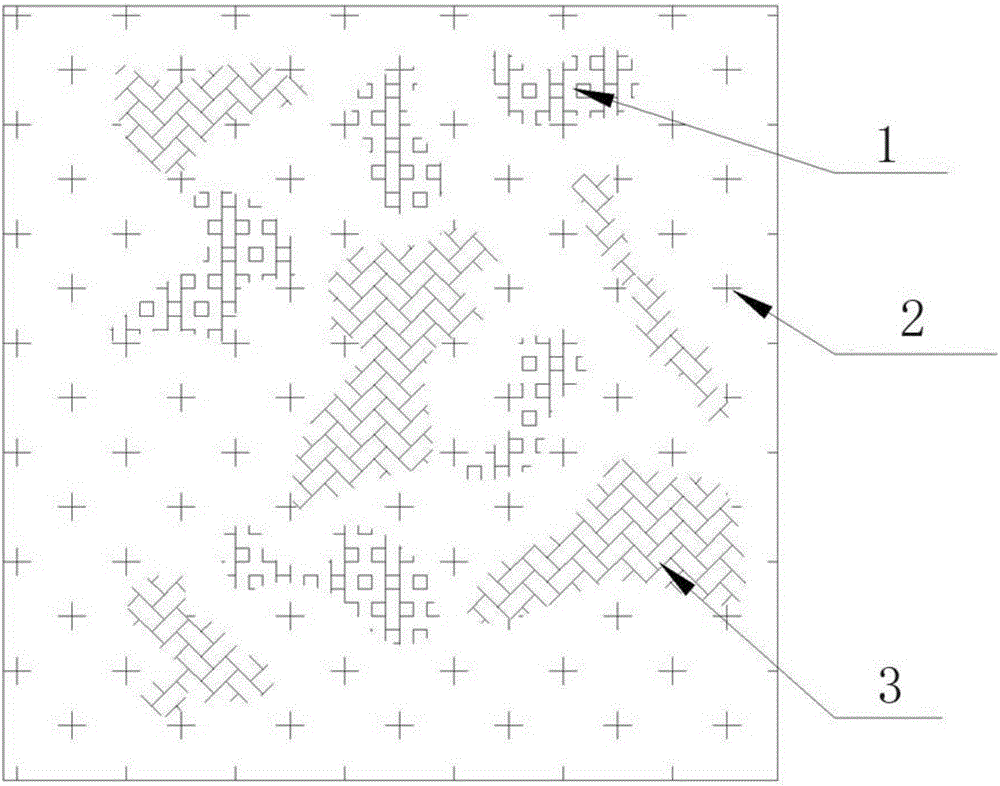

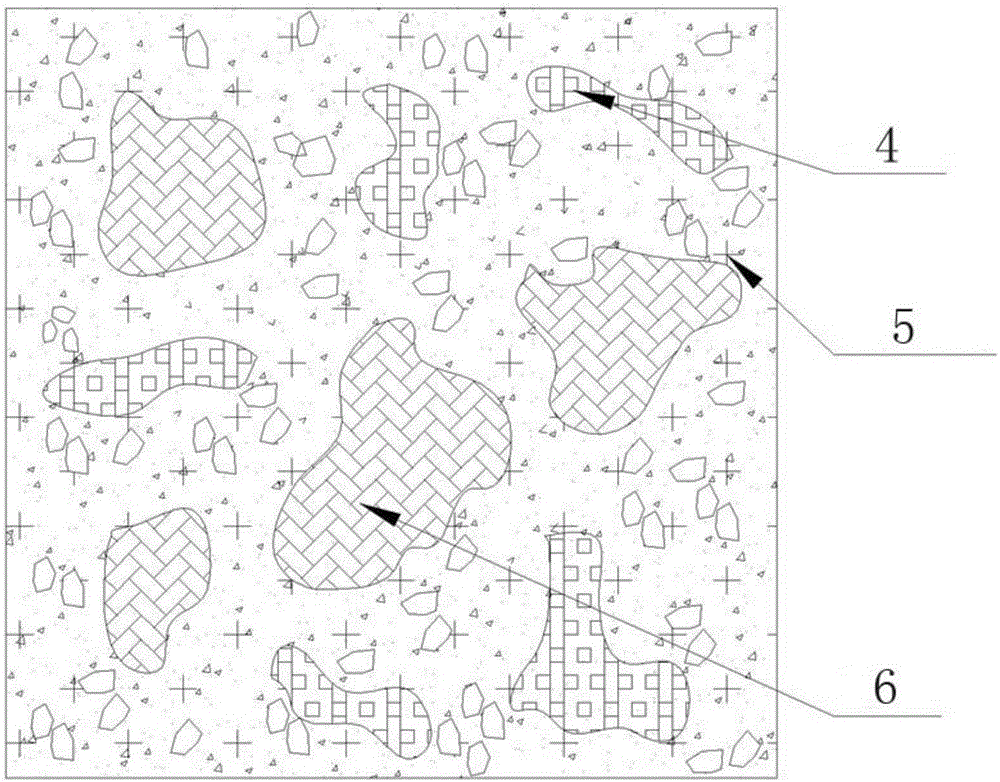

Image

Examples

Embodiment 1

[0047] (1), choose kaolin, feldspar, quartz and other raw sand materials, prepare the body porcelain powder A according to the conventional ceramic technology, the formula weight percentage is composed of silicon dioxide 65%, aluminum oxide 21.6%, potassium oxide + sodium oxide 6%, Calcium Oxide + Magnesium Oxide 1.5%, others are burning loss and trace impurities, use the color material for the billet, and use the conventional ceramic powder making process to prepare two different colors of porcelain powder A1 and A2, dark blue and extra black, of which Porcelain powder A1 is dark blue, and porcelain powder A2 is extra black, spare;

[0048] (2), according to the formula requirements for preparing the green body porcelain powder A, the formula weight percentage is composed of 65% silicon dioxide, 21.6% aluminum oxide, 6% potassium oxide+sodium oxide, 1.5% calcium oxide+magnesia oxide, and others In order to reduce burning and trace impurities, add 5% zirconium silicate and 2% ...

Embodiment 2

[0057] In steps (4) and (5) of Example 1, the extra black and dark blue color powder materials are broken into fine powders by using conventional porcelain polished tile micropowder distribution technology, and then crushed into pieces of different sizes by pre-pressing Blocky, granular, and fine powder mixed raw materials are controlled at a rate, and they are randomly distributed on the receiving belt under it, and the blank area left is filled into a spray tower containing a penetration enhancer that promotes the color of the penetrating ink. The prepared white powder of the conventional particle size of the ceramic tiles in the industry is then filled into and scraped the base material, and then sent to the press to be stamped and formed into bricks, and then enter the subsequent process. In this way, it is possible to obtain a body color pattern containing a sharp pattern texture formed by the clear boundary of the block-shaped green body pattern element itself and a block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com