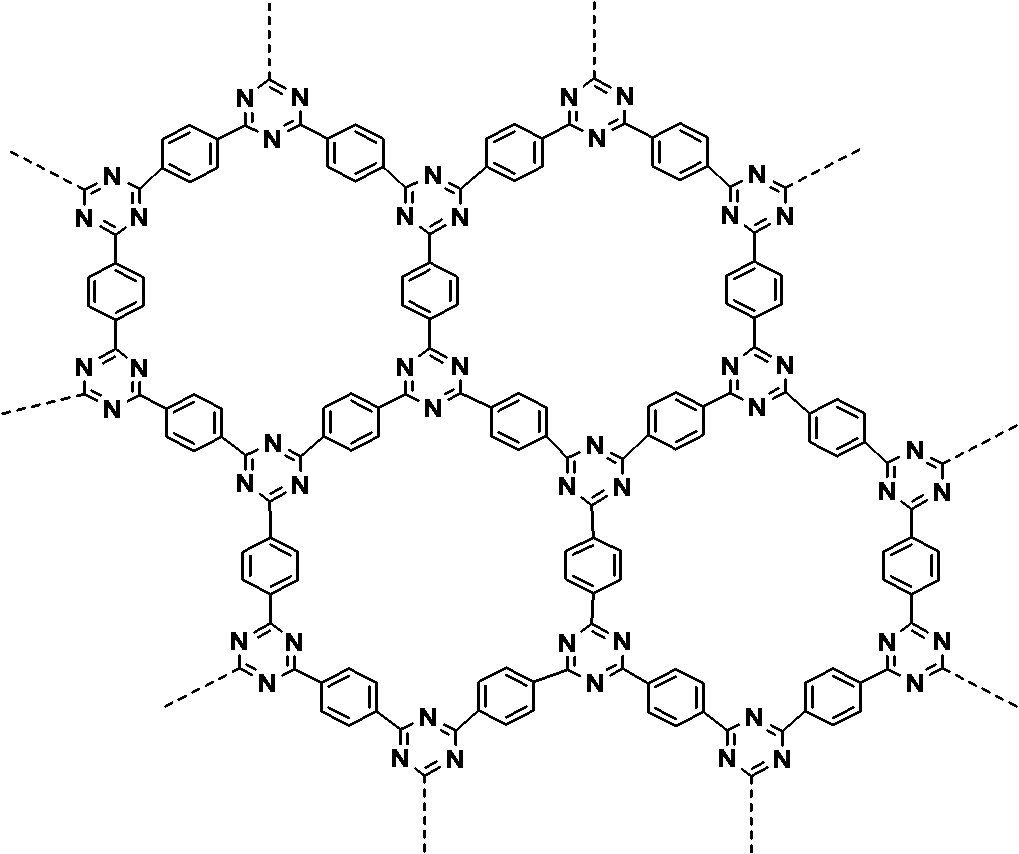

Application of porous covalent triazine polymer for removing aromatic compound from water

A technology of aromatic compounds and covalent triazines, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as difficult desorption, troublesome application and operation of adsorbents, and decreased adsorption efficiency , to achieve good adsorption effect, good adsorption reversibility, uniform pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The porous covalent triazine polymer synthesized above was used as an adsorbent to treat slightly polluted water containing benzene. The adsorption experiment was carried out in a 40mL transparent glass bottle equipped with a polytetrafluoroethylene gasket. The adsorption experiment adopted the traditional shaking flask method. In order to reduce the accidental error of the experiment, two sets of parallel samples were set up for the adsorption experiment. The mass ratio of adsorbent to slightly polluted water is 1:2000, the initial concentration of benzene is 2-40mg / L, pH=5.8-6.4, the temperature is set at room temperature, and the adsorption equilibrium time is 24h. The removal rate of benzene is 38%-70%.

[0032] The desorption method used in the experiment: static settling or centrifugation to remove most of the supernatant in the reaction vessel, then add an equal amount of distilled water for desorption, and react for 20-30 hours.

Embodiment 2

[0034] The porous covalent triazine polymer synthesized above was used as an adsorbent to treat slightly polluted water containing naphthalene. Adsorption conditions are the same as in Example 1. The mass ratio of the experimental adsorbent to slightly polluted water is 1:2000, the initial concentration of naphthalene is 1.4-27mg / L, pH=5.8-6.4, the temperature is set at room temperature, the adsorption time is 24h, and the removal rate of naphthalene is 96%~ 98%.

Embodiment 3

[0036] Condition is the same as embodiment 1. The temperature is set at room temperature, the initial concentration of phenol is 2-60mg / L, and its removal rate is 30%-61%. The initial concentration of naphthol is 18-90mg / L, and its removal rate is 92%-99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com