Method for preparing foamed aluminum by foaming melt

A technology of melt foaming and aluminum foam, which is applied in the field of preparation of aluminum foam, can solve problems such as high requirements for equipment and environmental parameters, failure to meet diversified requirements, and increased production costs, so as to reduce production costs and reduce production costs. Equipment requirements, effect of uniform pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

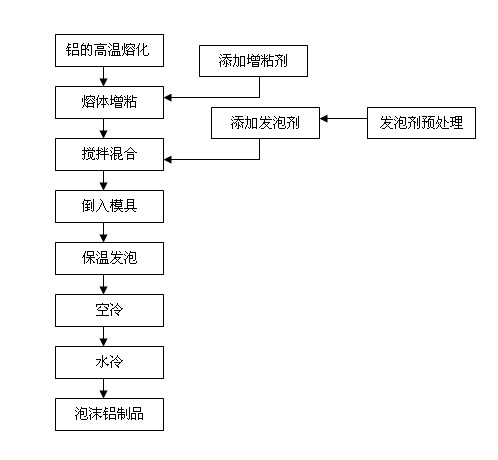

[0032] Embodiment one: Such as figure 1 Shown, a kind of method for preparing foamed aluminum by one-shot melt foaming, described method step comprises.

[0033] (1) Cut the aluminum into ingots, put the aluminum ingot into the crucible, start the thermoelectric furnace to heat to 800°C, and keep it warm for 1 to 30 minutes to completely melt the aluminum.

[0034] (2) Add metallic calcium to the molten aluminum when the temperature of the molten aluminum drops to 680°C by adjusting the thermoelectric furnace. The amount of calcium added is between 1% and 4% of the relative weight of aluminum; while adding calcium, use a mixer to stir and stir The optimal time is 1 to 35 minutes, so that the calcium is evenly distributed in the molten aluminum and fully mixed with the molten aluminum so that the surface viscosity of the melt increases.

[0035] (3) Pretreat titanium hydride, and add the pretreated titanium hydride to the melt when the melt temperature drops to 650°C by adj...

Embodiment 2

[0038] Embodiment two: Such as figure 1 Shown, a kind of method for preparing foamed aluminum by one-shot melt foaming, described method step comprises.

[0039] (1) Cut the aluminum into ingots, and the length of the ingots is best controlled at 5-10mm; put the aluminum ingots into the crucible, start the thermoelectric furnace and heat it to 800°C, so that the aluminum is completely melted into aluminum liquid.

[0040] (2) Add metallic calcium to the molten aluminum when the temperature of the molten aluminum drops to 680°C by adjusting the thermoelectric furnace. The amount of calcium added is between 1% and 4% of the relative weight of aluminum; while adding calcium, use a mixer to stir and stir The best time is 1-35 minutes, and the best stirring speed is 4500rpm, so that the calcium can be evenly distributed in the molten aluminum and fully mixed with the molten aluminum to increase the surface viscosity of the melt.

[0041] (3) Pretreatment of titanium hydride by ...

Embodiment 3

[0045] Embodiment three: Such as figure 1 Shown, a kind of method for preparing foamed aluminum by one-shot melt foaming, described method step comprises.

[0046] (1) Cut the aluminum into ingots, and the length of the ingots is best controlled at 5-10mm; put the aluminum ingots into the crucible, start the thermoelectric furnace and heat it to 800°C, so that the aluminum is completely melted and turned into aluminum liquid.

[0047] (2) Add metallic calcium to the molten aluminum when the temperature of the molten aluminum drops to 680°C by adjusting the thermoelectric furnace. The amount of calcium added is between 1% and 4% of the relative weight of aluminum; while adding calcium, use a mixer to stir and stir The best time is 1-35 minutes, and the best stirring speed is 4500rpm, so that the calcium can be evenly distributed in the molten aluminum and fully mixed with the molten aluminum to increase the surface viscosity of the melt.

[0048] (3) Coating titanium hydrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com