Preparation method of silicon dioxide aerogel

A technology of silica and airgel, applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of sol particle diffusion limitation, uneven pore structure, and larger airgel particles, and achieve Improved optical transparency and mechanical properties, uniform pore structure, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention provides a method for preparing silica airgel, comprising the following steps:

[0038] Step 1, hydrolyzing and polymerizing methyltrimethoxysilane to obtain a wet gel;

[0039] Specifically, in the embodiment of the present invention, silica wet gel can be prepared by sol-gel technology by alkali-catalyzed method, acid-catalyzed method or acid-base two-step method;

[0040] Step 2, standing the wet gel at a certain temperature to obtain a shrunken wet gel;

[0041] Specifically, in the embodiment of the present invention, the resting temperature is preferably 0-70°C, and the resting time can be adjusted according to the requirements for airgel density; the resting temperature is more preferably 20-40°C, and the resting time is preferably 2-12 hours , to ensure that the wet gel does not appear cracks, broken, etc.;

[0042] Step 3, sealing and aging the shrunk wet gel with a solvent;

[0043] Specifically, the solvent can be sm...

Embodiment 1

[0059] Weigh 60 parts by mass of solvent water, add 0.05 parts by mass of acetic acid, then add 0.6 parts by mass of surfactant cetyltrimethylammonium chloride, stir well and add 30 parts by mass of precursor methyl trimethoxy base silane was stirred for hydrolysis.

[0060] The hydrolysis temperature is 25° C., and the hydrolysis time is 0.5 hour.

[0061] Mix 0.06 parts by mass of alkaline catalyst ammonia water and 30 parts by mass of solvent water, add them into the hydrolyzed sol system, stir evenly, and catalyze polymerization at 25° C. to obtain a liquid sol.

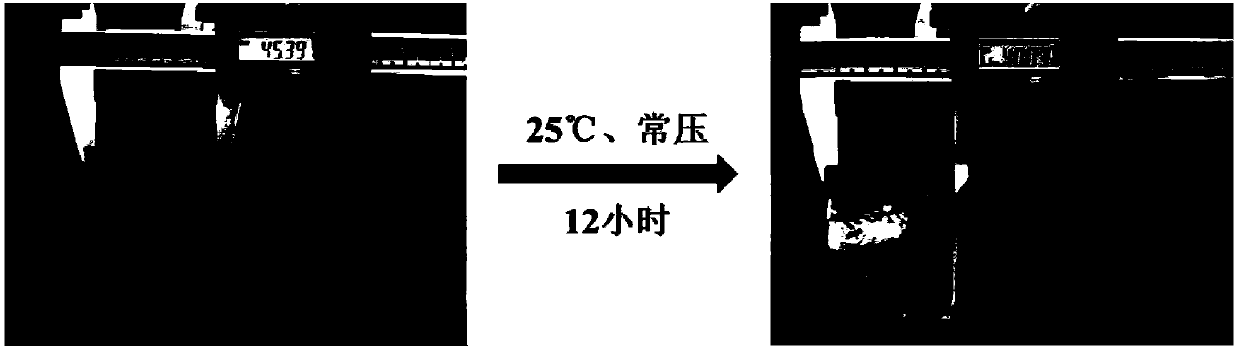

[0062] Inject the sol into a suitable mold and let it stand still. When it reaches the gel point, a wet gel is obtained, and the wet gel is removed from the mold and placed at 25°C under normal pressure for 12 hours to obtain a shrinking wet gel. glue, wet gel shrinkage process such as figure 1 shown.

[0063] Move the shrunk wet gel into an ethanol bath for aging, the aging temperature is 60°C, the aging time...

Embodiment 2

[0067] It is basically the same as Example 1, the only difference is that after standing to the gel point, continue to stand for 20 minutes to obtain a wet gel, and remove the wet gel from the mold and place it under normal pressure at 25°C for 10 hours, A shrinking wet gel is obtained. The optical transparency of the airgel is as Figure 5 as shown in b;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com