Liquefied petroleum gas dechlorination adsorbent and application method thereof

A technology of liquefied petroleum gas and an application method, which is applied in the field of liquefied petroleum gas dechlorination adsorbents, can solve the problems of frequent regeneration and decreased chloride removal effect, and achieves large adsorption and dechlorination capacity, high adsorption and dechlorination efficiency, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

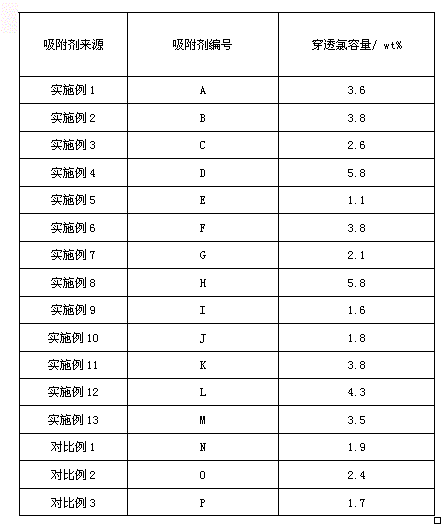

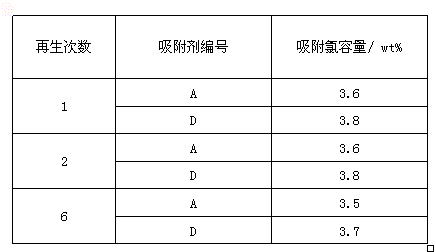

Examples

example 1

[0026] 700 grams of average particle size Φ3mm (the average particle size of molecular sieves in other embodiments is the same) NaY molecular sieve (silicon-aluminum atomic molar ratio is 3, specific surface area 550m 2 / g) The carrier was added to 1500 milliliters of aqueous solution containing 583 grams of magnesium nitrate and impregnated for 5 hours, then dried at 150° C. for 4 hours, then roasted in air at 540° C. for 2 hours, and then impregnated with 1000 milliliters of aqueous solution containing 122 grams of zinc nitrate for 4 hours. Hours, then dried at 150°C for 4 hours, and calcined in air at 540°C for 2 hours to obtain Adsorbent A.

[0027] Adsorbent A is composed of 77wt% molecular sieve, 17.3wt% magnesium oxide and 5.7wt% zinc oxide.

example 2

[0029] The average particle size is less than 5μmNaY molecular sieve (dry basis, silicon aluminum atomic molar ratio is 5, specific surface area is 430m 2 / g ) mixed with pseudo-boehmite and kaolin, and then rolled into Φ3mm balls, wherein the content of alumina is 20wt%, the content of kaolin is 30wt%, and the content of molecular sieve is 50wt%.

[0030] Take 500 grams of the above-mentioned Φ3mm balls and add them to 1500 milliliters of aqueous solution containing 583 grams of magnesium nitrate and immerse them for 5 hours, then dry them at 150°C for 4 hours, then roast them in air at 500°C for 2 hours, and then use 3000 milliliters of 610 grams of zinc nitrate The aqueous solution was impregnated three times, the amount of each solution was 1000 ml, impregnated for 4 hours, and after each impregnation, it was dried at 150° C. for 4 hours and roasted in air at 500° C. for 2 hours to obtain adsorbent B.

[0031] The composition of adsorbent B is 27.5wt% of molecu...

example 3

[0033] Add 700 grams of average particle size Φ3mm NaY molecular sieve (same as Example 1) carrier into 1500 milliliters of aqueous solution containing 698 grams of magnesium nitrate and soak for 5 hours, then dry at 150°C for 4 hours, and then roast at 540°C for 2 hours to obtain the adsorbent C, its composition is molecular sieve 83wt%, magnesium oxide 17wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com