Method for preparation of composite chromatographic stuffing of polymer carbon nanometer tube

A carbon nanotube composite and chromatographic filler technology is applied in the field of preparation of polymer carbon nanotube composite high-performance liquid chromatography columns, and can solve the problems of low rigidity of organic matrix fillers, non-specific irreversible adsorption, and easy expansion and contraction. , to achieve the effect of low cost, narrow particle size distribution and enhanced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

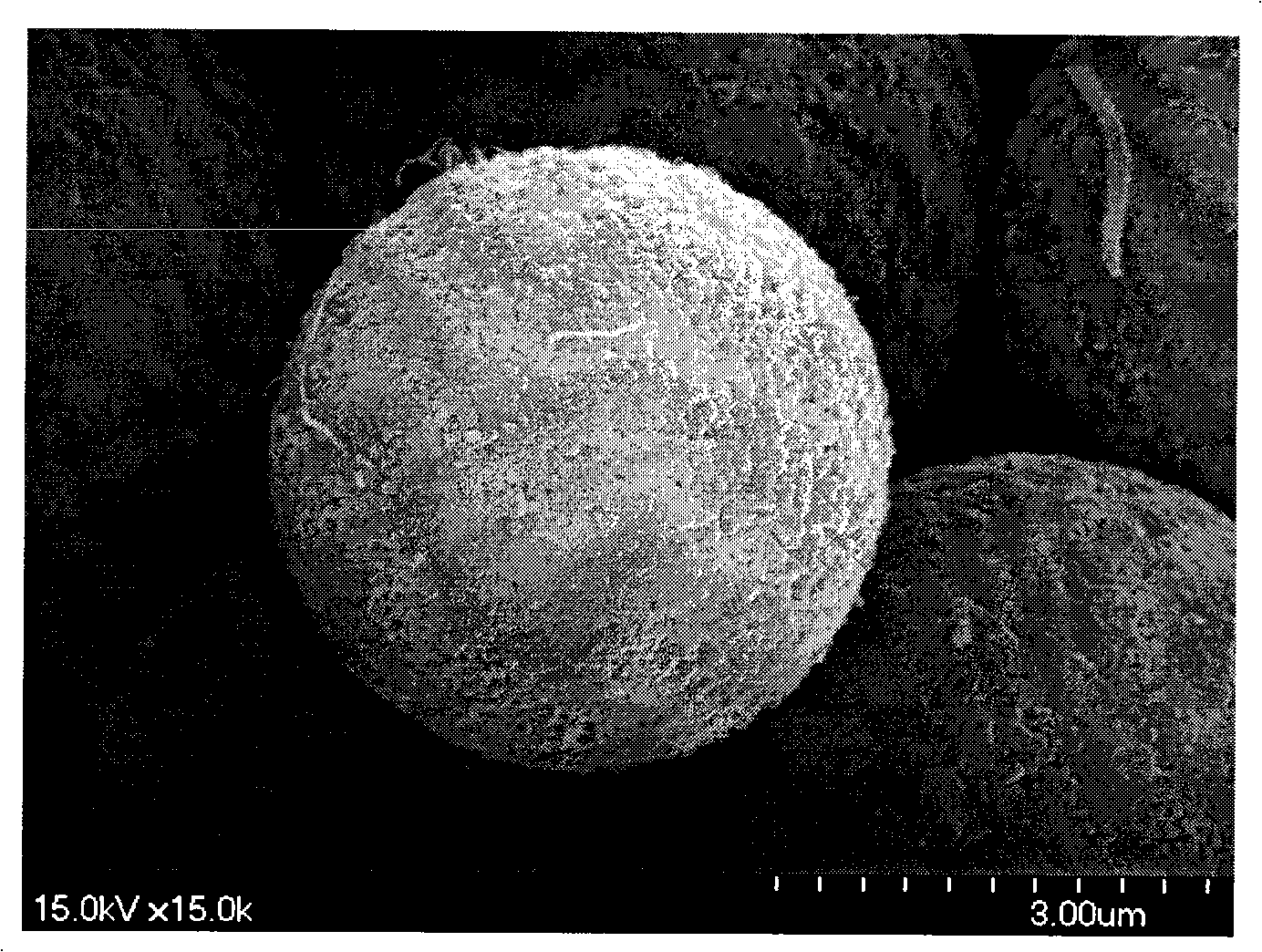

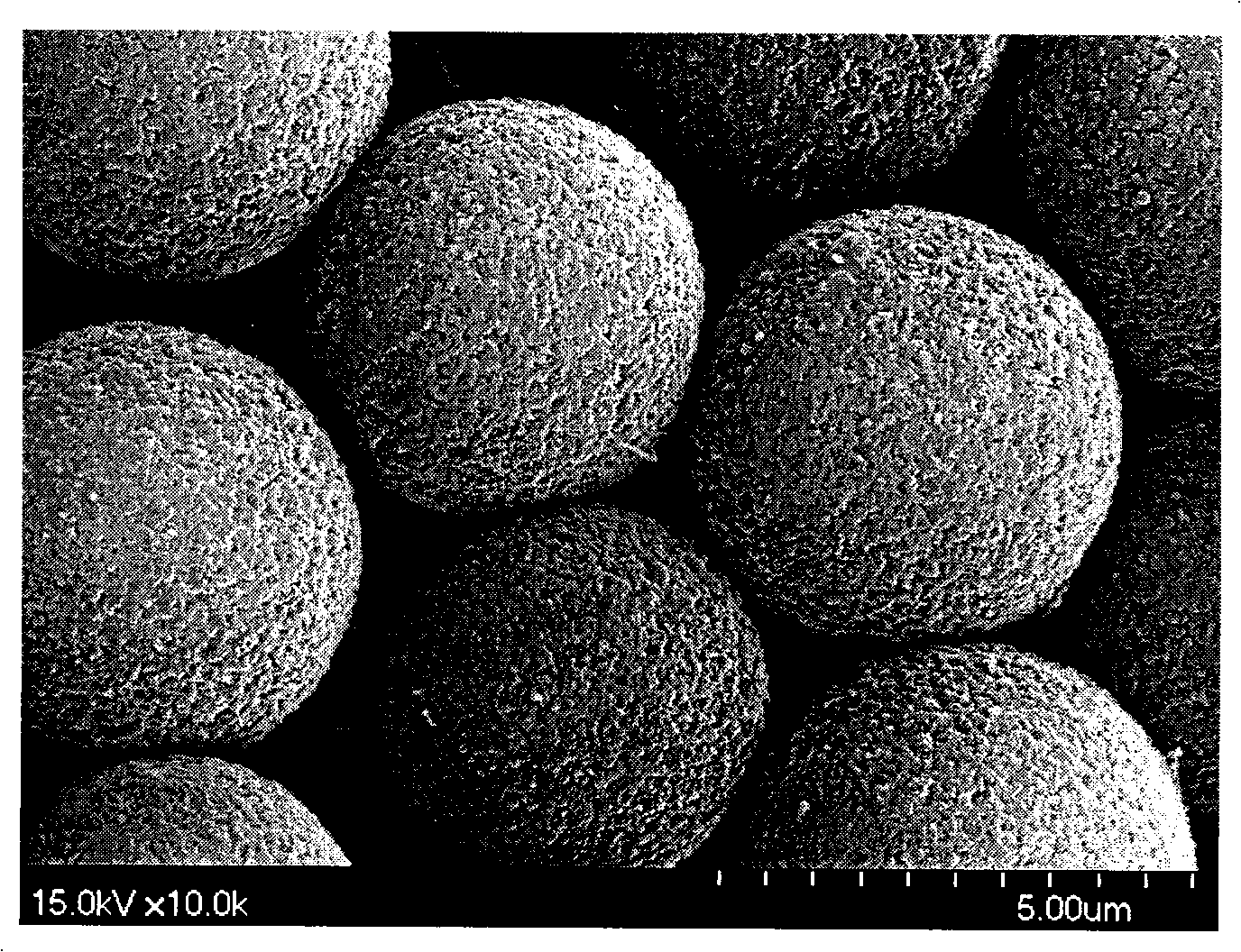

[0023] Embodiment 1: the making process of polymer carbon nanotube composite chromatographic filler is as follows, and its steps are:

[0024] 1. Synthesize monodisperse polystyrene seeds with a particle size of 1 to 3 μm by dispersion polymerization, the concentration of monomeric styrene is 5 to 30% (m / m) of the total amount, and the amount of stabilizer polyvinylpyrrolidone is the reaction medium 0.5-4% (m / v), the amount of initiator azobisisobutyronitrile is 1-5% (m / m) of the monomer amount, the reaction medium is ethanol aqueous solution, and the concentration is 75-100% (v / v ), the reaction temperature is 40-85° C., the stirring speed is 100-400 rpm, and the reaction time is 8-24 hours.

[0025] 2. Then prepare monodisperse polystyrene-divinylbenzene-carbon nanotube composite microspheres with a crosslinking degree of 10-75% by seed swelling method. The concentration of monomer styrene is 10-20% (m / m) of the total organic phase, and the range of cross-linking degree of ...

Embodiment 2

[0030] With reference to the method and steps of embodiment 1

[0031] 1. First synthesize 1.8 μm monodisperse polystyrene seeds by dispersion polymerization, the concentration of monomer styrene is 20%, the amount of stabilizer polyvinylpyrrolidone is 1.5%, and the amount of initiator azobisisobutyronitrile is 2%. The medium is 95% ethanol aqueous solution, the reaction temperature is 80° C., the stirring speed is 400 rpm, and the reaction time is 24 hours.

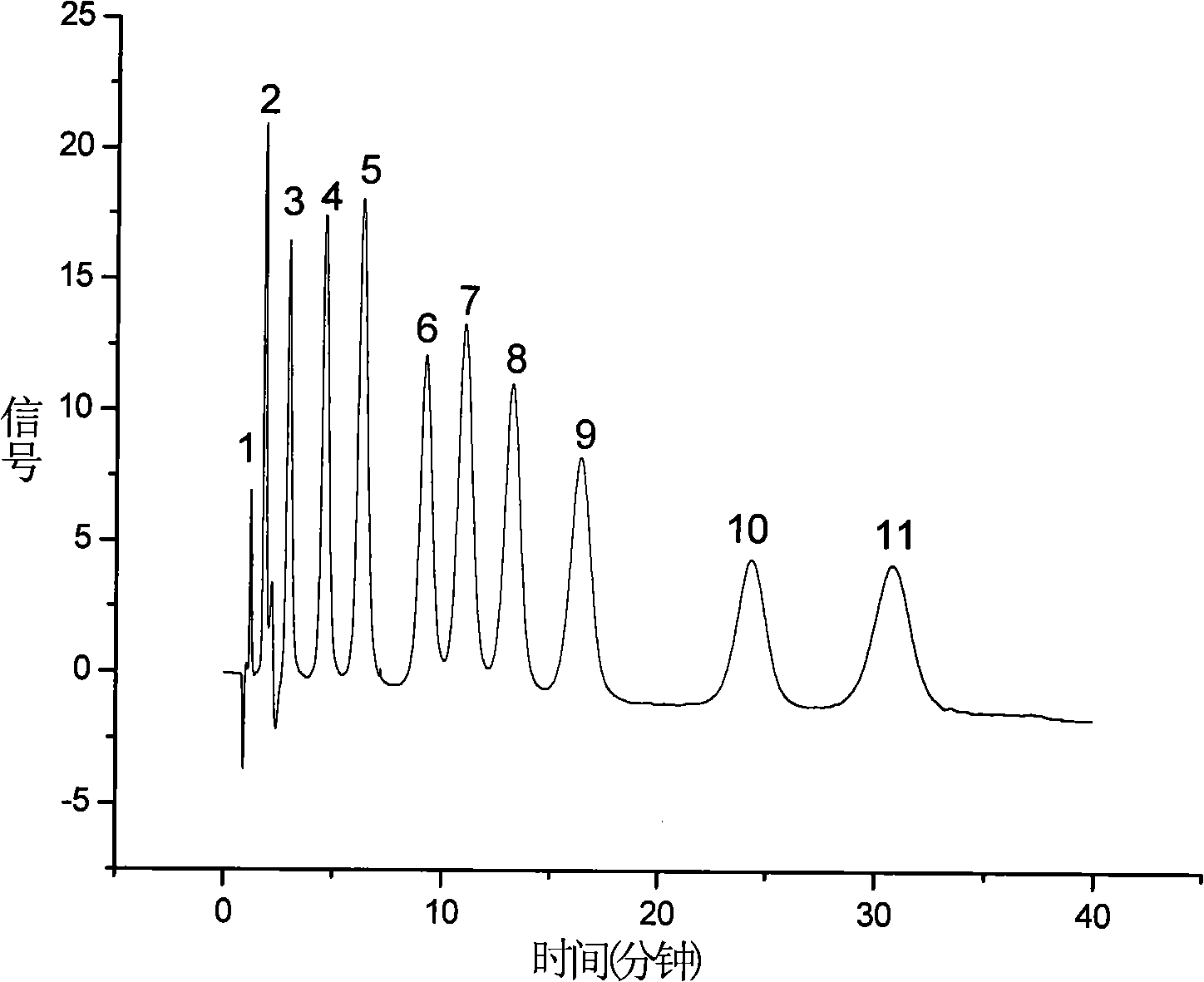

[0032] 2. At the same time, the carbon nanotubes were treated with hydrogen peroxide, and then monodisperse polystyrene-divinylbenzene-carbon nanotube composite microspheres with a crosslinking degree of 55% were prepared by the seed swelling method, and the monomer styrene concentration was 12%. The content of carbon nanotubes accounts for 0.5% of monomer styrene, the amount of emulsifier sodium lauryl sulfate is 2%, the amount of stabilizer polyvinyl alcohol is 1%, and the amount of initiator benzoyl peroxide is 0.5%. ...

Embodiment 3

[0038] (1) Synthesize 1.8 μm monodisperse polystyrene seed by dispersion polymerization method earlier, monomer concentration is 20%, stabilizer consumption is 1.5%, initiator consumption is 2%, reaction medium is 95% ethanol aqueous solution, reaction temperature 80 °C, the stirring speed was 400 rpm, and the reaction time was 24 hours.

[0039] (2) The carbon nanotubes were oxidized with nitric acid, and then the monodisperse polystyrene-divinylbenzene-carbon nanotube composite microspheres with a crosslinking degree of 55% were prepared by the seed swelling method. The monomer concentration is 10%, the content of carbon nanotubes accounts for 0.8% of the monomer, the amount of emulsifier is 2.8%, the amount of stabilizer is 1%, the amount of initiator is 0.5%, the amount of porogen is 60%, and the swelling ratio 50, the emulsification temperature is 20°C, the reaction temperature is 75°C, the stirring speed is 300 rpm, and the reaction time is 48 hours.

[0040] (3) The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com