Preparation method of monolithic BEA molecular sieve catalyst for direct N2O catalysis decomposition

A catalytic decomposition and molecular sieve technology, which is applied in the fields of chemical engineering and environmental protection, to achieve high-efficiency removal, low conversion temperature, and stable catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of 5% aluminum sol Fe-BEA monolithic molecular sieve catalyst

[0039] Accurately weigh the H-BEA molecular sieve catalyst (SiO 2 / Al 2 o 3 =30) (commercial molecular sieve) 10.0g, Fe(NO 3 ) 3 9H 2 O (analytical pure) 0.729g, deionized water 300mL, put it in a three-necked flask, and stir in a constant temperature water bath at 90°C for 6 hours. Then it was filtered and washed 3 times, dried in a drying oven at 100°C for 12 hours, then placed in a muffle furnace to program the temperature to 550°C, and roasted at a constant temperature for 5 hours to obtain a Fe ion-modified BEA molecular sieve powder sample, in which Fe The mass percentage of ions in the modified molecular sieve is 1%.

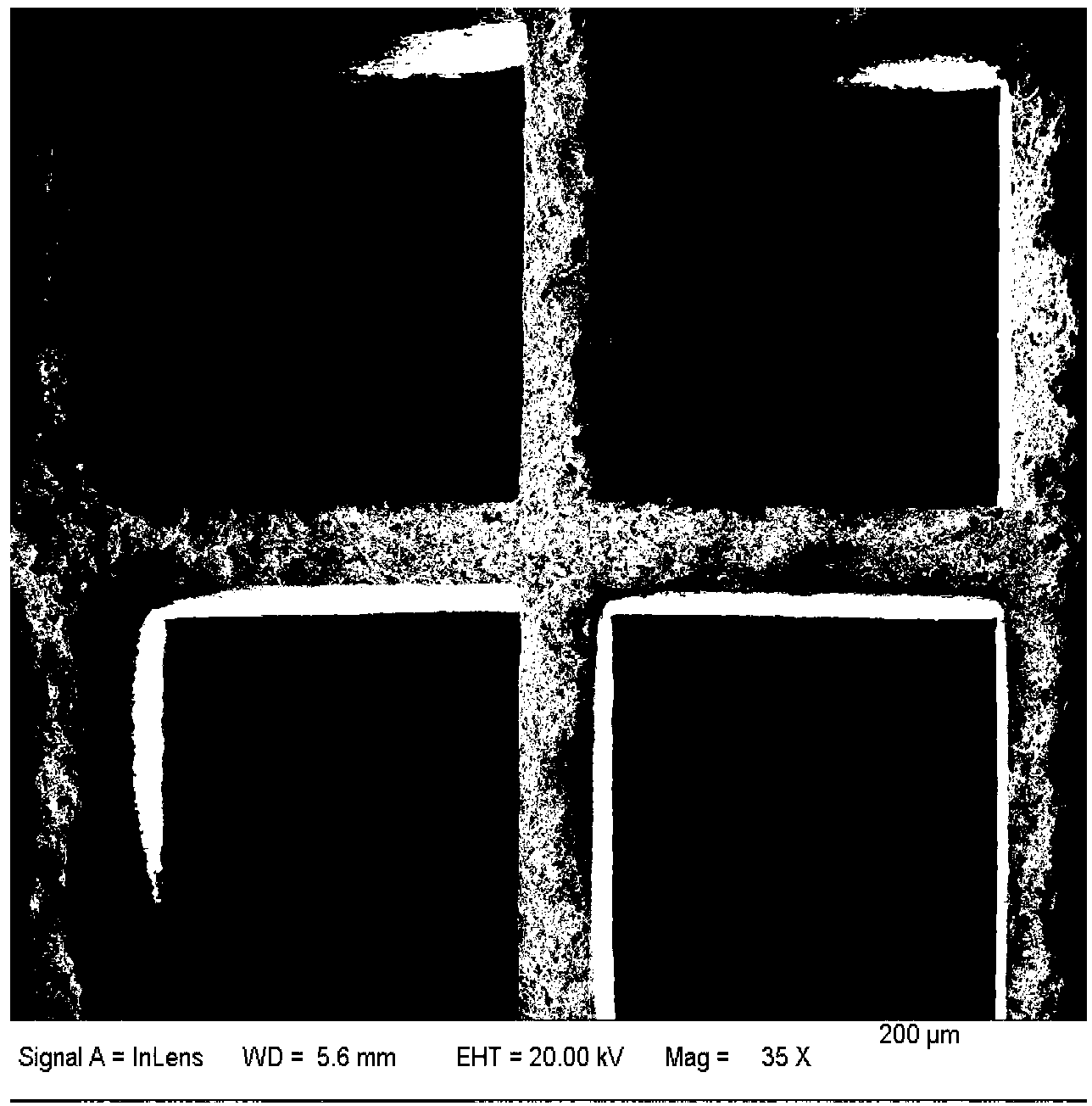

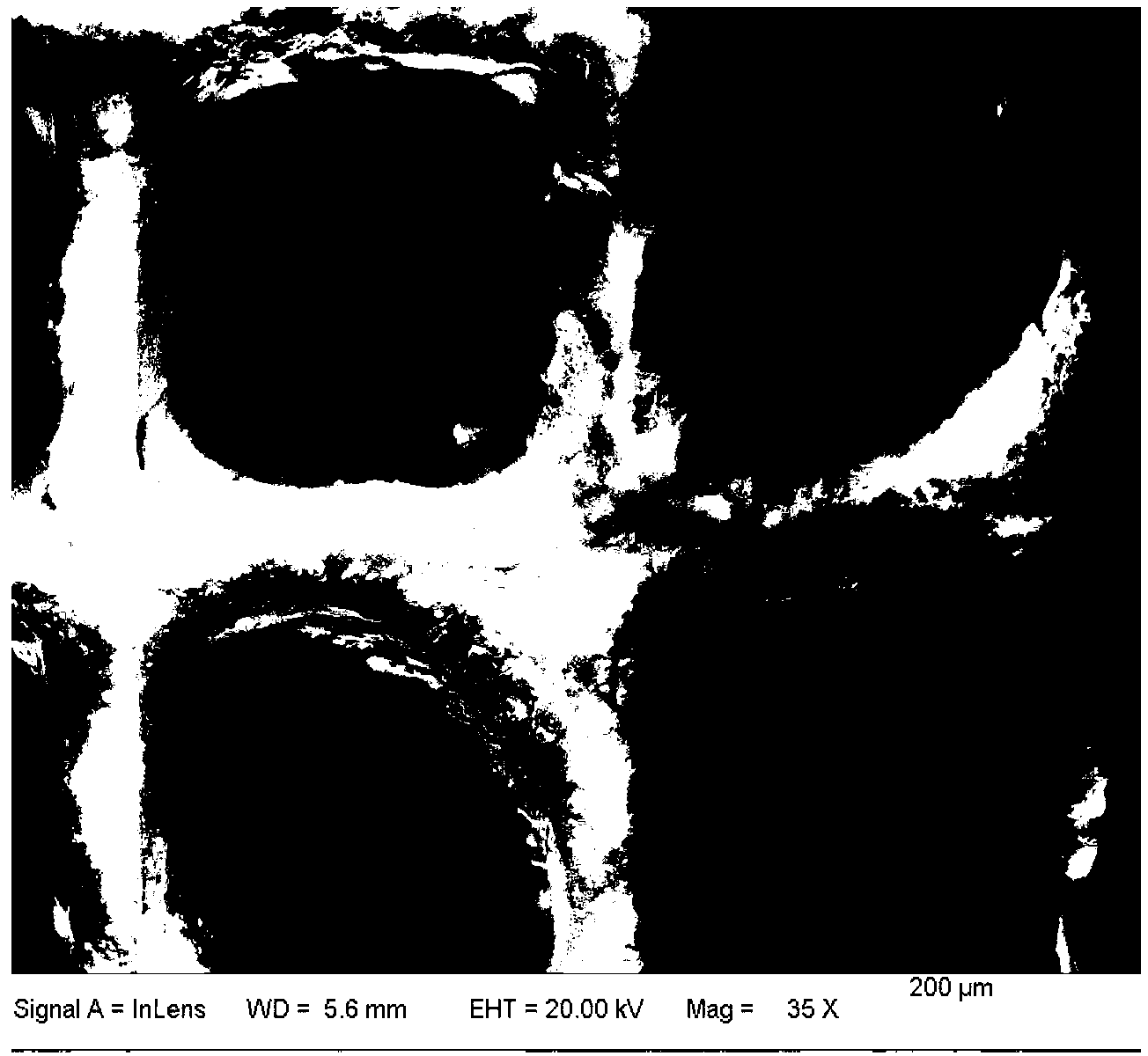

[0040] A large piece of cordierite (diameter 16.5mm, height 11mm, hole density 400cell / inch 2 ) into a small piece of cordierite with a hole number of 10×10, then grind it to a height of 5mm, and finally pick it into the required cylindrical shape with a p...

Embodiment 2

[0043] Example 2: Preparation of 10% aluminum sol Fe-BEA monolithic molecular sieve catalyst

[0044] The preparation of Fe-BEA powder molecular sieve is as described in Example 1. Select aluminum sol with a mass percentage of 20% as a binder, accurately weigh 4.000 g of Fe-BEA molecular sieve, 6.858 g of aluminum sol, and 2.824 g of deionized water. The rest of the preparation steps are as described in Example 1, and a Fe-BEA monolithic molecular sieve catalyst with 10% aluminum sol and a Fe-BEA loading capacity of 41.5% can be obtained. The activity evaluation means are the same as in Example 1, and the activity evaluation results are shown in Table 1.

Embodiment 3

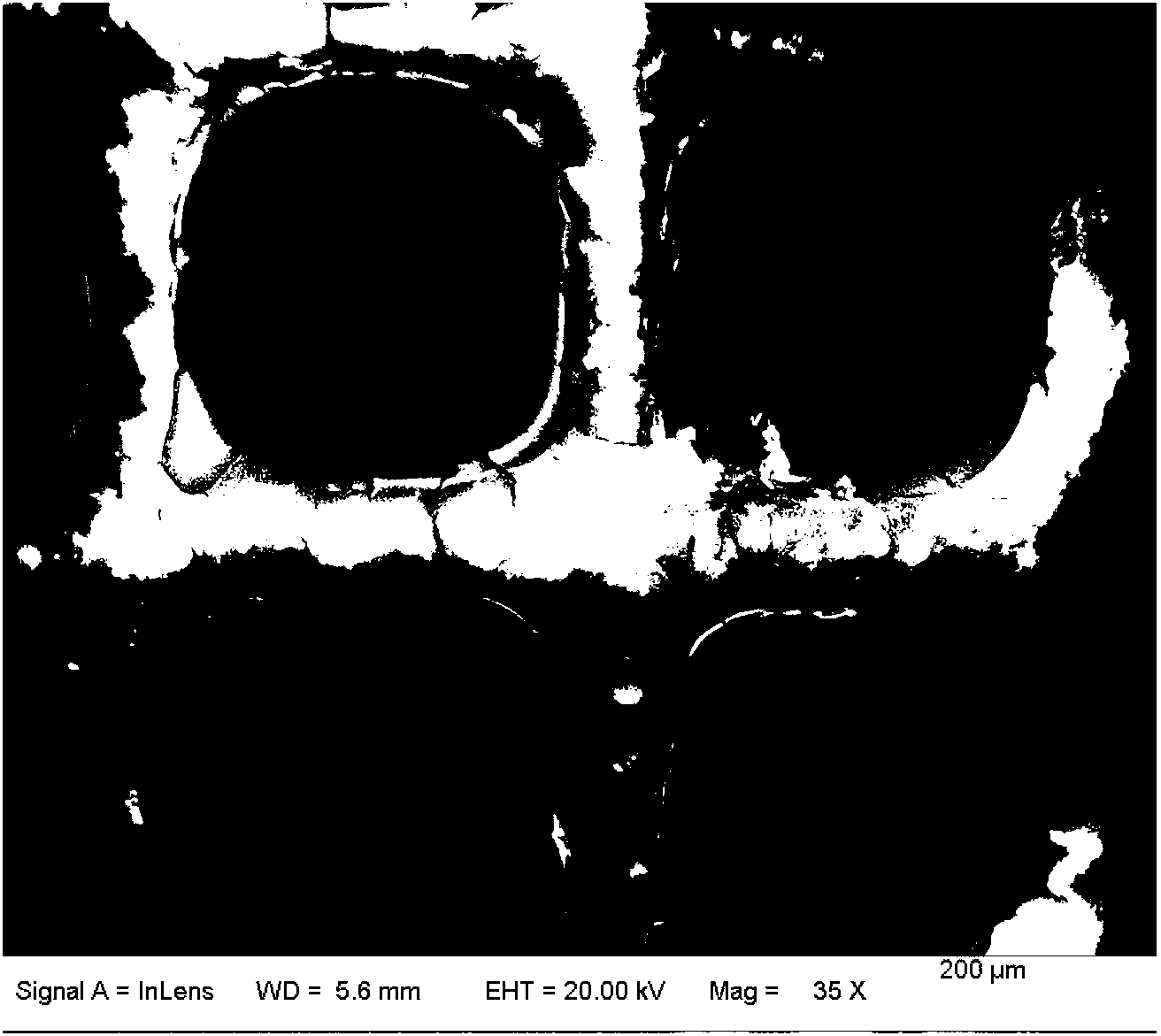

[0045] Example 3: Preparation of 5% silica sol Co-BEA monolithic molecular sieve catalyst

[0046] Accurately weigh 10.0 g of H-BEA molecular sieve catalyst (commercial molecular sieve), Co(NO 3 ) 3 ·6H 2 O (analytical pure) 0.490g and deionized water 300mL, the rest of the preparation steps are the same as the preparation process of Fe-BEA modified molecular sieve in Example 1 to obtain Co-BEA powder molecular sieve, wherein Co accounts for the mass of modified molecular sieve (Co-BEA) The percentage is 1%.

[0047] The pretreatment of the original carrier of cordierite is the same as in Example 1.

[0048] Select silica sol with a mass percentage of 30% as a binder, accurately weigh 4.000 g of Co-BEA molecular sieve, 2.131 g of silica sol, and 6.528 g of deionized water. The remaining preparation steps are as described in Example 1, and 5% silica sol, 48.0% (mass percentage, based on the Co-BEA monolithic molecular sieve catalyst, the same below) Co-BEA monolithic molecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com