Coating composite for lithium ion battery separator and foam gluing method

A coating composition, lithium ion technology, applied to battery components, coatings, circuits, etc., can solve the problem of uneven pore size distribution of battery separators, improve service life and performance, good adhesion, and not easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

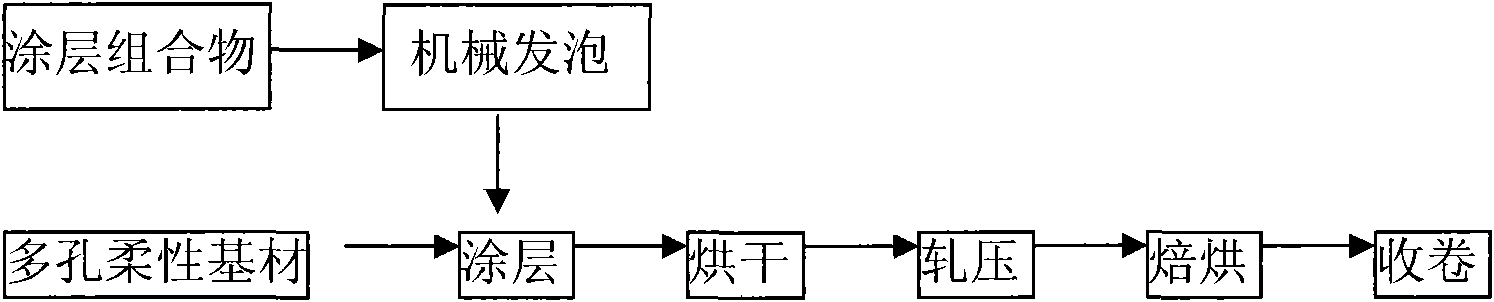

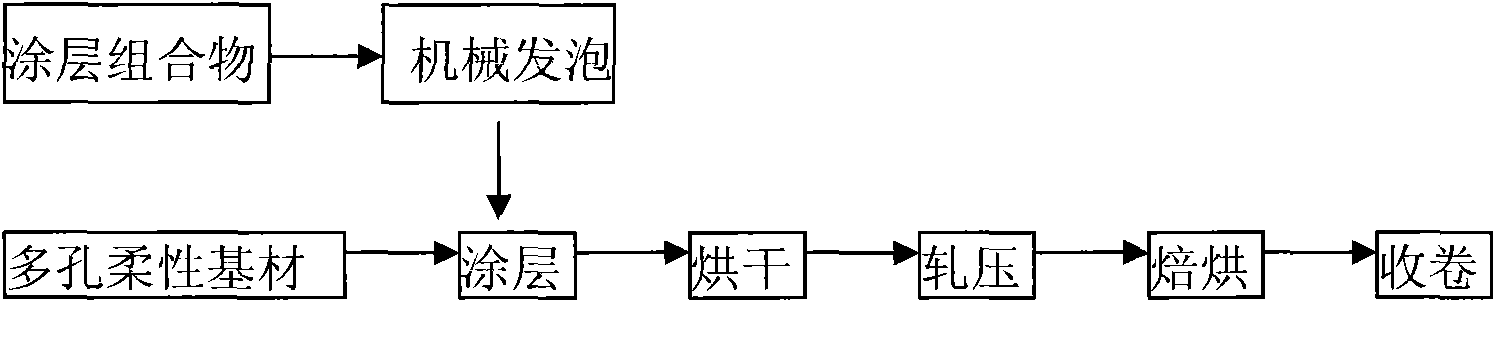

Method used

Image

Examples

Embodiment 1

[0037] A coating composition for a lithium-ion power battery diaphragm, consisting of the following components in parts by weight:

[0038] Acrylate emulsion 30 parts;

[0039] 30 parts of alumina powder;

[0040] Foaming agent (sodium lauryl sulfate) 2 parts;

[0041] 3 parts of foam stabilizer (lauryl alcohol);

[0042] 35 parts of water.

[0043] Step 1. Mix acrylate emulsion, alumina powder, sodium lauryl sulfate, lauryl alcohol and 3 parts by weight of alkali-thickening acrylate emulsion in proportion, and adjust the viscosity to 2000mPa·s;

[0044] Step 2. Foaming the above suspension and adjusting the foam density to about 250 g / L. Use the foam applicator to evenly coat the foam on the porous flexible substrate;

[0045] Step 3. Dry the foam coating coated on the porous flexible substrate at a temperature of 90°C for 3 minutes, so that the moisture content reaches about 10%. After rolling at 45N / cm, bake at 130°C Bake for 1 min, and wind up to obtain a lithium-ion...

Embodiment 2

[0048] A coating composition for a lithium-ion power battery diaphragm, consisting of the following components in parts by weight:

[0049] Acrylate emulsion 50 parts;

[0050] 10 parts of alumina powder;

[0051] 0.5 parts of blowing agent (sodium lauryl sulfate);

[0052] 1 part of foam stabilizer (dodecyl alcohol);

[0053] 38.5 parts of water.

[0054] Step 1. Mix acrylate emulsion, alumina powder, sodium lauryl sulfate, lauryl alcohol and 1 part by weight of alkali-thickening acrylate emulsion in proportion, and adjust the viscosity to 3000mPa·s;

[0055] Step 2. Foaming the above suspension and adjusting the foam density to about 200 g / L. Use the foam applicator to evenly coat the foam on the porous flexible substrate;

[0056] Step 3. Dry the foam coating coated on the porous flexible substrate at a temperature of 120°C for 1 minute to make the moisture content reach about 10%. After rolling at 294N / cm, bake it at 160°C Bake for 3 minutes, and wind up to obtain a ...

Embodiment 3

[0059] A coating composition for a lithium-ion power battery diaphragm, consisting of the following components in parts by weight:

[0060] 40 parts of acrylate emulsion;

[0061] 20 parts of alumina powder;

[0062] 1.5 parts of foaming agent (sodium lauryl sulfate);

[0063] 2 parts of foam stabilizer (dodecyl alcohol);

[0064] 36.5 parts of water.

[0065] Step 1. Mix acrylate emulsion, alumina powder, sodium lauryl sulfate, lauryl alcohol and 2 parts by weight of alkali-thickening acrylate emulsion in proportion, and adjust the viscosity of the coating composition to 2500mPa·s;

[0066] Step 2. Foaming the above suspension and adjusting the foam density to about 210 g / L. Use the foam applicator to evenly coat the foam on the porous flexible substrate;

[0067] Step 3. Dry the foam coating coated on the porous flexible substrate at a temperature of 110°C for 3 minutes, so that the moisture content reaches about 10%. After rolling at 150N / cm, bake at 150°C Bake for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com