Polyimide-base nano fibrous membrane, and preparation method and application thereof

A nanofiber membrane, polyimide-based technology, used in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of danger of polyimide diaphragms, and achieve convenient preparation, uniform pore structure and distribution. , the effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

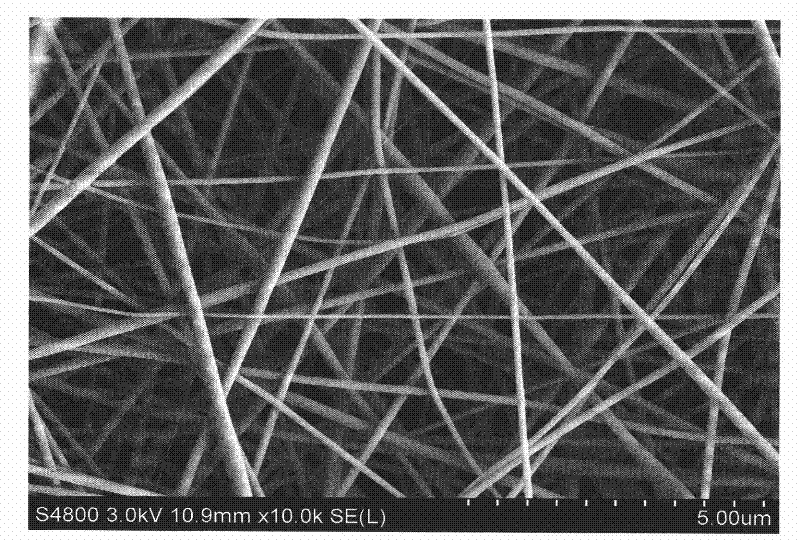

Embodiment 1

[0048] Add 4.36 grams of pyromellitic dianhydride, 4.00 grams of diaminodiphenyl ether, and 45.5 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C , the reaction time was 24 hours to obtain a uniform polyamic acid solution (15% by mass fraction). After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.6667 g of polyamic acid solution in a 50 ml volumetric flask, add N,N-dimethylacetamide to make it volume to 50 ml, prepare a solution of 0.0050 g / ml, and use an Ubbelohde viscometer in a water bath at 30°C Its intrinsic viscosity was determined to be 2.11dL / g. Another 1.0 ml of polyamic acid solution was taken out for electrospinning, the diameter of the needle was 1.6 mm, the spinning voltage was 100 volts, the height from the needle tip to the receiving plate was 20 cm, and the electrospinning was performed for 2 hours to obtain a polyamide with a thickness of 9...

Embodiment 2

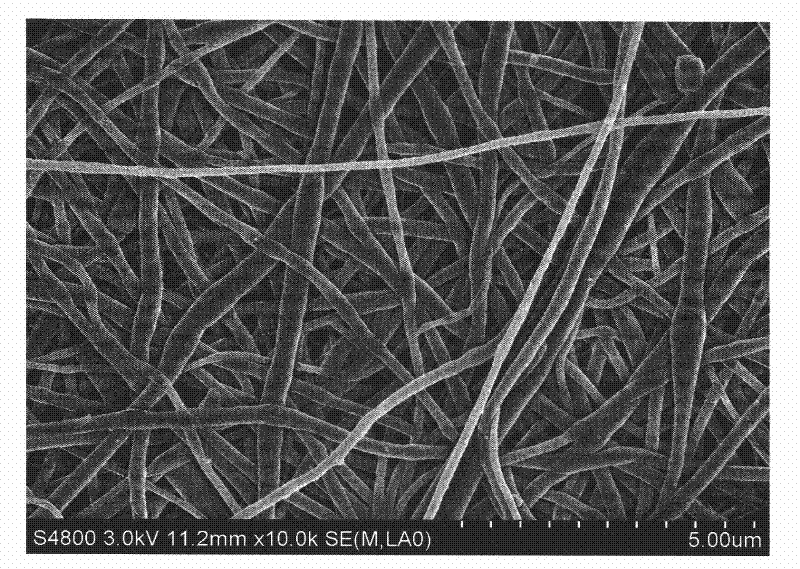

[0050] Add 5.88 grams of biphenyltetracarboxylic dianhydride, 4.97 grams of diphenylsulfone diamine, and 60.3 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C , the reaction time was 24 hours to obtain a uniform polyamic acid solution (15% by mass fraction). After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.6667 g of polyamic acid solution in a 50 ml volumetric flask, add N,N-dimethylacetamide to make it volume to 50 ml, prepare a solution of 0.0050 g / ml, and use an Ubbelohde viscometer in a water bath at 30°C Its intrinsic viscosity was determined to be 1.89dL / g. Another 1.0 ml of polyamic acid solution was taken out for electrospinning, the diameter of the needle was 1.6 mm, the spinning voltage was 2 kV, the height from the needle tip to the receiving plate was 20 cm, and the electrospinning was performed for 2 hours to obtain a nanometer with a thickn...

Embodiment 3

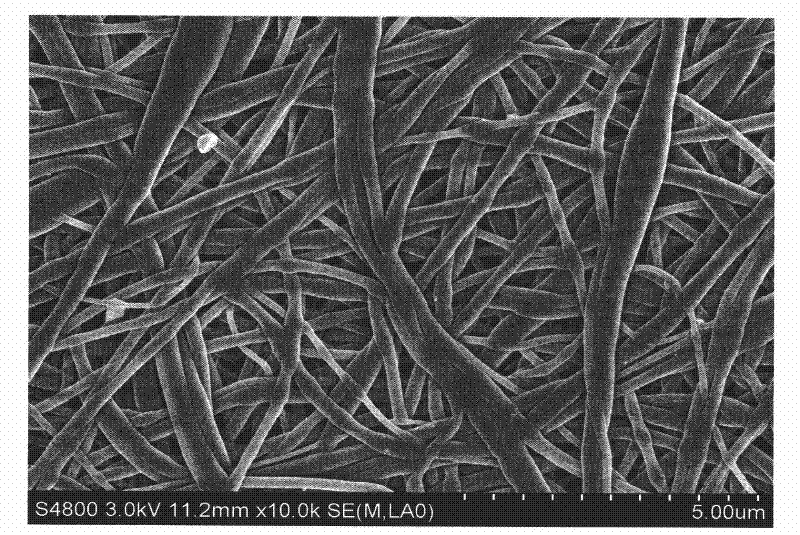

[0052] Add 5.88 grams of biphenyltetracarboxylic dianhydride, 2.16 grams of p-phenylenediamine, and 43.4 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C. The reaction time was 24 hours, and a uniform polyamic acid solution (15% by mass fraction) was obtained. After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.6667 g of polyamic acid solution in a 50 ml volumetric flask, add N,N-dimethylacetamide to make it volume to 50 ml, prepare a solution of 0.0050 g / ml, and use an Ubbelohde viscometer in a water bath at 30°C Its intrinsic viscosity was determined to be 1.49dL / g. Another 1.0 ml of polyamic acid solution was taken out for electrospinning, the diameter of the needle was 1.6 mm, the spinning voltage was 25.0 kV, the height from the needle tip to the receiving plate was 20 cm, and the electrospinning was performed for 2 hours to obtain a nanometer with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com