Needling static filter cotton and preparation method thereof

A technology of acupuncture and filter cotton, which is applied in the field of air purification, can solve the problems of high filtration resistance, low strength, high porosity, etc., and achieve the effects of small filtration resistance, large dust holding capacity, good strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

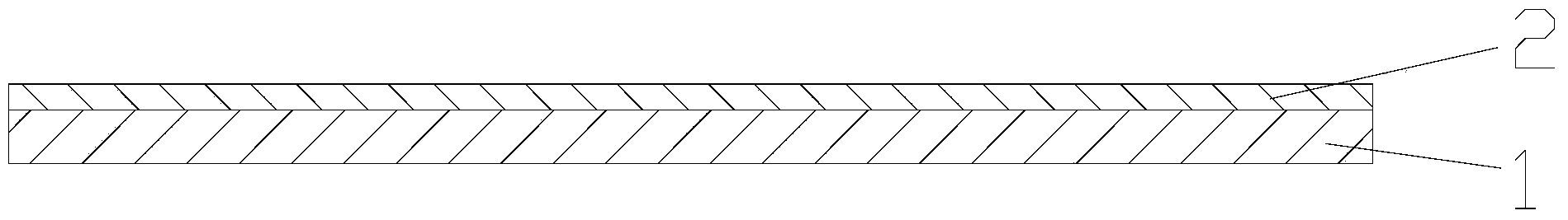

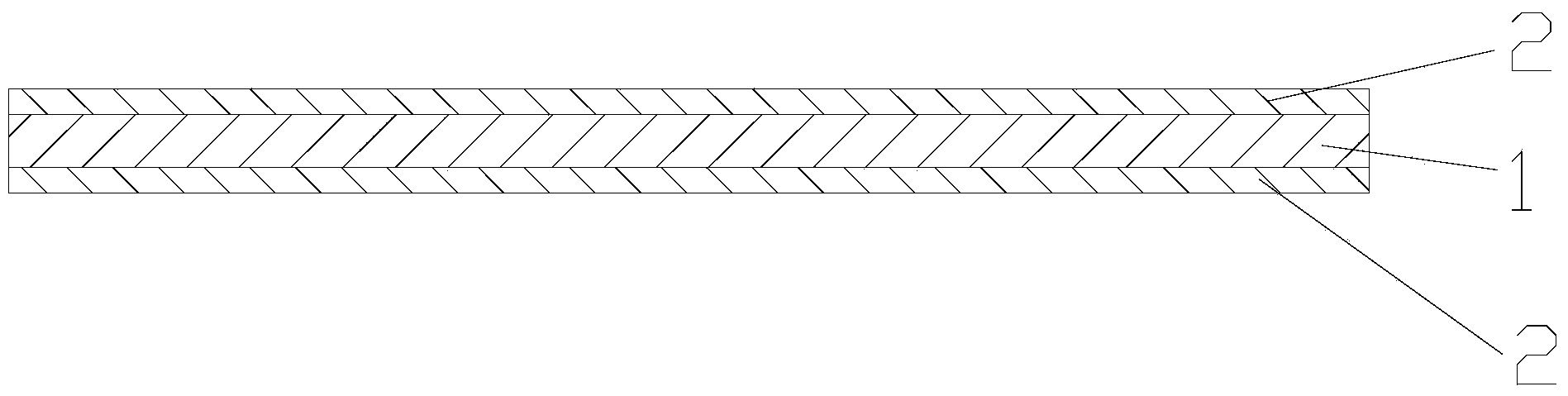

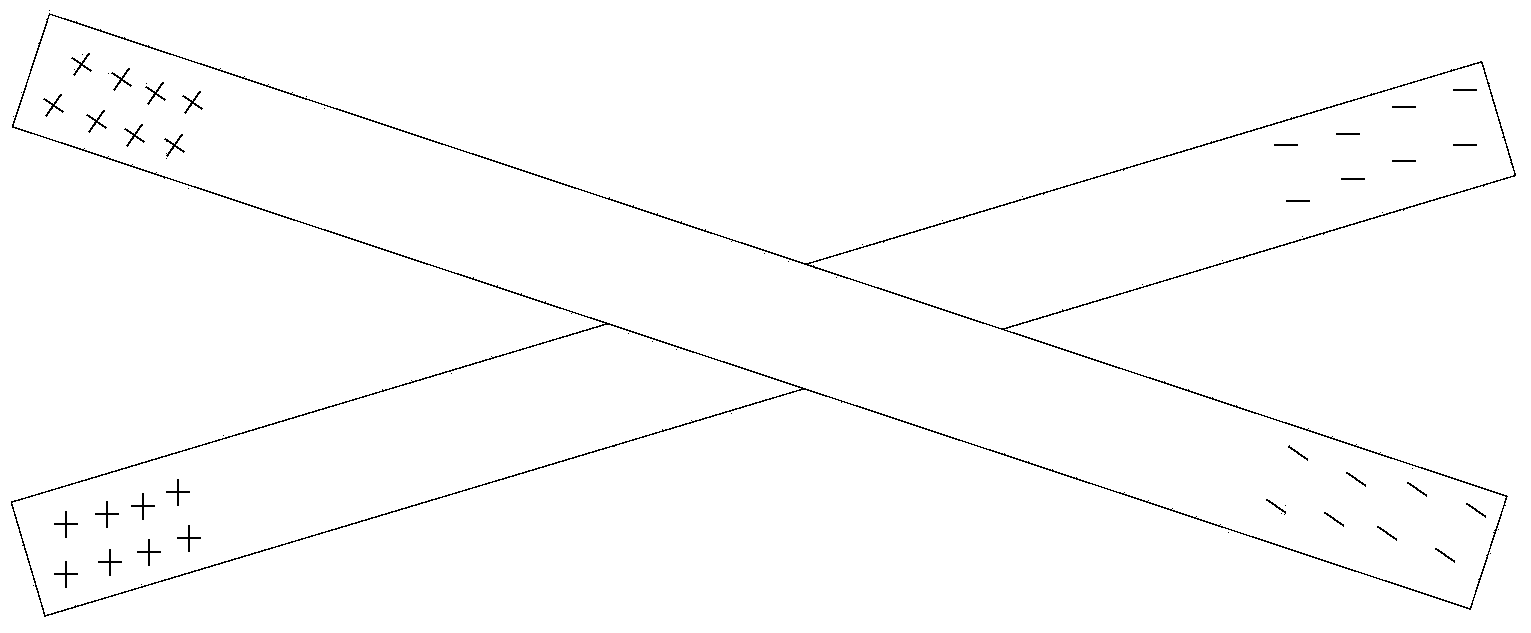

Image

Examples

Embodiment 1

[0039] Embodiment 1: a kind of preparation method of acupuncture electrostatic filter cotton, this method comprises the steps:

[0040] 1) Fabrication of needle-punched non-woven layer: The chopped polypropylene fibers are loosened, mixed, carded, and laid in sequence to make a relatively fluffy polypropylene fiber web, and the weight of the polypropylene fiber web is 35g / m 2 , the degree of longitudinal fiber orientation is 87, and the ratio of longitudinal and transverse strength is 2.9; then, the polypropylene fiber web is processed on the front and back sides by two needle punches, and the needle punch density is 155 punches / cm 2 , Reinforced into a needle-punched non-woven layer, the working temperature of the production workshop is controlled at 22-26°C, and the humidity is controlled at 50-60%RH.

[0041] 2) Drying process: pre-dry the needle-punched non-woven layer obtained in step 1), and then bake to obtain needle-punched filter cotton; the pre-drying temperature is ...

Embodiment 2

[0048] 1) Production of needle-punched non-woven layer: The polypropylene chopped fibers are opened, mixed, carded, and laid in turn to make a relatively fluffy polypropylene fiber web. The degree of orientation is 76, and the aspect ratio is 2.5. Then, the polypropylene fiber web is processed on the front and back sides by two needle punches, and the needle punch density is 206 punches / cm 2 , Reinforced into a needle-punched non-woven layer, the working temperature of the production workshop is controlled at 22-26°C, and the humidity is controlled at 50-60%RH.

[0049] 2) Drying process: pre-dry the needle-punched non-woven layer obtained in step 1), and then bake to obtain needle-punched filter cotton; the pre-drying temperature is 40°C, the curing temperature is 50°C, and the drying temperature is 50°C. The drying time is 2 minutes.

[0050] 3) Pass the acupuncture filter cotton treated in step 2) through a high-voltage corona discharge electric field, the voltage is 46KV...

Embodiment 3

[0056] 1) Production of needle-punched non-woven layer: The polypropylene chopped fibers are opened and mixed, carded, and laid in turn to make a relatively fluffy polypropylene fiber web. The degree of orientation is 45, and the aspect ratio is 1.6. Then, the polypropylene fiber web is processed on the front and back sides by two needle punches, and the needle punch density is 438 punches / cm 2 , Reinforced into a needle-punched non-woven layer, the working temperature of the production workshop is controlled at 22-26°C, and the humidity is controlled at 50-60%RH.

[0057] 2) Drying process: pre-dry the needle-punched non-woven layer obtained in step 1), and then bake to obtain needle-punched filter cotton; the pre-drying temperature is 50°C, the baking temperature is 65°C, and the drying temperature is 65°C. The drying time is 3 minutes.

[0058] 3) Pass the acupuncture filter cotton treated in step 2) through a high-voltage corona discharge electric field, the voltage is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com