Double-layer filter material for internal combustion engine

A double-layer filter and internal combustion engine technology, which is applied in the direction of filter separation, layered products, mechanical equipment, etc., can solve the problems of limited filter efficiency of filter materials, and achieve the effects of wide performance control range, improved filter efficiency, and high dust holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, double-layer filter material for internal combustion engine air filtration

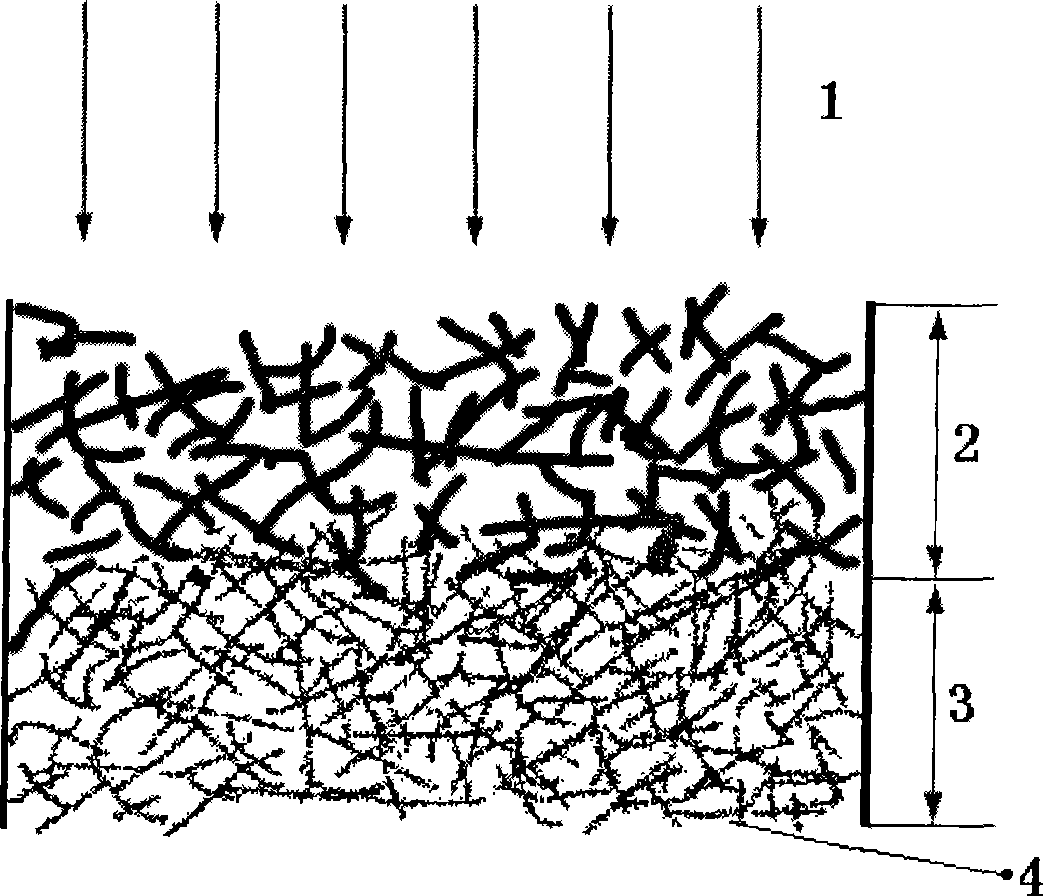

[0024] The structure of double-layer filter material for internal combustion engine is as follows: figure 1 As shown, a coarse filter layer 2 and a fine filter layer 3 are arranged according to the fluid flow direction 1 .

[0025] The coarse filter layer 2 is made up of 82% coarse filter natural fibers and 18% synthetic fibers by mass fraction; wherein the coarse filter natural fibers have an average diameter of 18 μm and an average length of 8 mm; the synthetic fibers have an average diameter of 20 μm, The average length is 8mm.

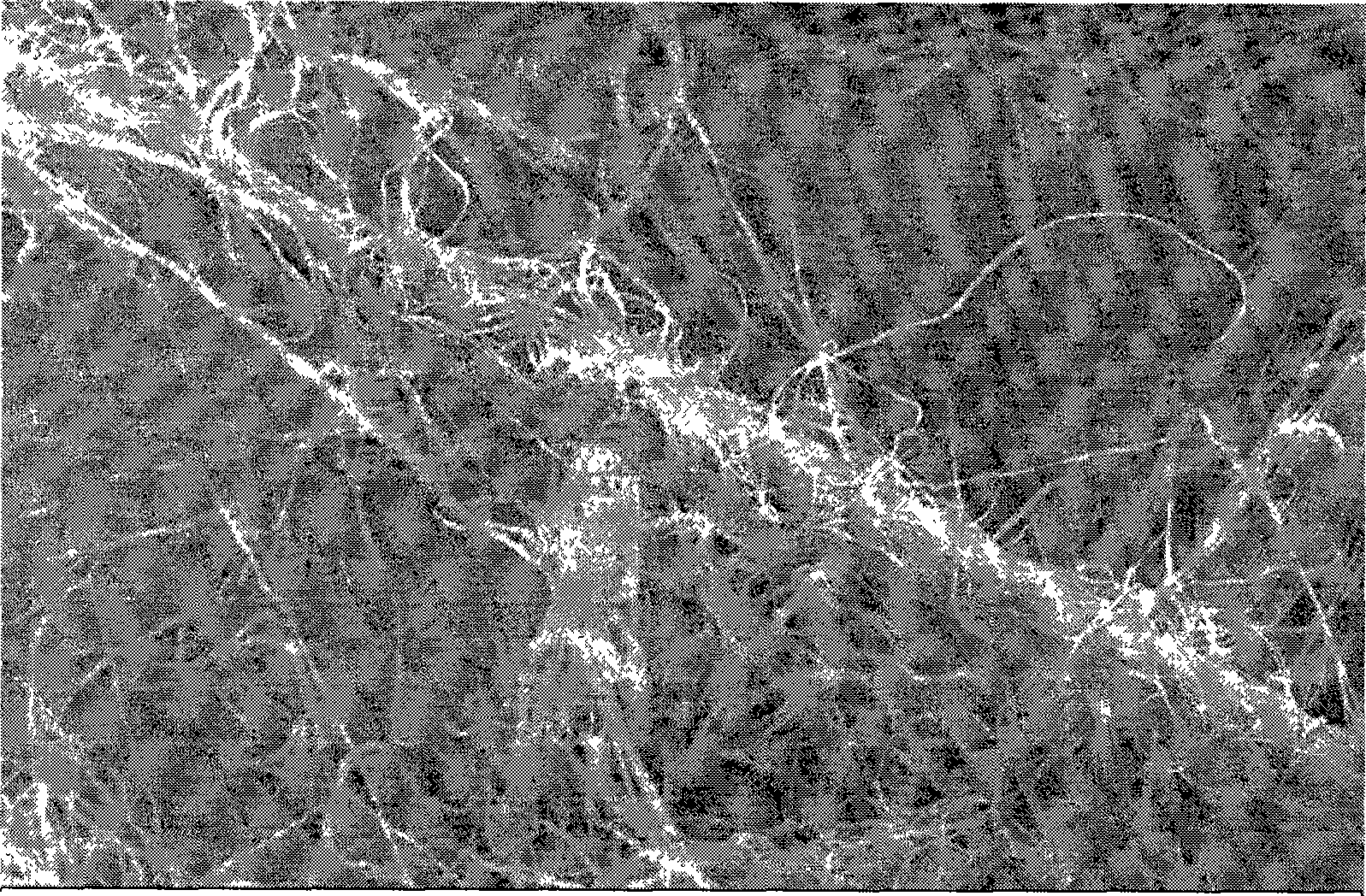

[0026] The fine filter layer 3 is composed of fibrillated fibers 4 with a mass fraction of 50% and natural fibers in the fine filter layer; wherein the average diameter of the fiber trunk of the fibrillated fibers 4 is 12 μm, the average length is 6 mm, and the beating degree is 30 0 SR; The natural fibers of the fine filter layer have an average dia...

Embodiment 2

[0029] Embodiment 2, double-layer filter material for internal combustion engine oil filtration

[0030] The structure of double-layer filter material for internal combustion engine is as follows: figure 1 As shown, a coarse filter layer 2 and a fine filter layer 3 are arranged according to the fluid flow direction 1 .

[0031] The coarse filter layer 2 is made up of 85% coarse filter natural fibers and 15% synthetic fibers by mass fraction; wherein the coarse filter natural fibers have an average diameter of 45 μm and an average length of 5 mm; the synthetic fibers have an average diameter of 25 μm, The average length is 20mm.

[0032] The fine filter layer 3 is composed of fibrillated fibers 4 with a mass fraction of 5% and fine filter layer natural fibers with a mass fraction of 95%; wherein the fiber trunk average diameter of the fibrillated fibers 4 is 18 μm, and the average length is 9 mm. The degree is 15°SR; the average diameter of natural fibers in the fine filter l...

Embodiment 3

[0035] Embodiment 3, the double-layer filter material that is used for internal combustion engine fuel oil filtration

[0036] The structure of double-layer filter material for internal combustion engine is as follows: figure 1 As shown, a coarse filter layer 2 and a fine filter layer 3 are arranged according to the fluid flow direction 1 .

[0037] The coarse filter layer 2 is made up of 88% coarse filter natural fibers and 12% synthetic fibers by mass fraction; wherein the average diameter of the coarse natural fibers is 60 μm, and the average length is 7 mm; the average synthetic fiber diameter is 30 μm, The average length is 20mm.

[0038] The fine filter layer 3 is composed of 100% fibrillated fibers 4 with an average trunk diameter of 3 μm, an average length of 1 mm, and a beating degree of 60°SR.

[0039] Wherein the fibrillated fiber 4 is a mixture of fibrillated Tencel fiber and Lisa fiber. The natural fibers of the coarse filter layer are mercerized plant fibers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com