Toughness tube (pipe) type filtration machine

A filter and tube-type technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of filter cloth wear, cleaning difficulty, size limitation, etc., achieve simple structure and avoid excessive displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

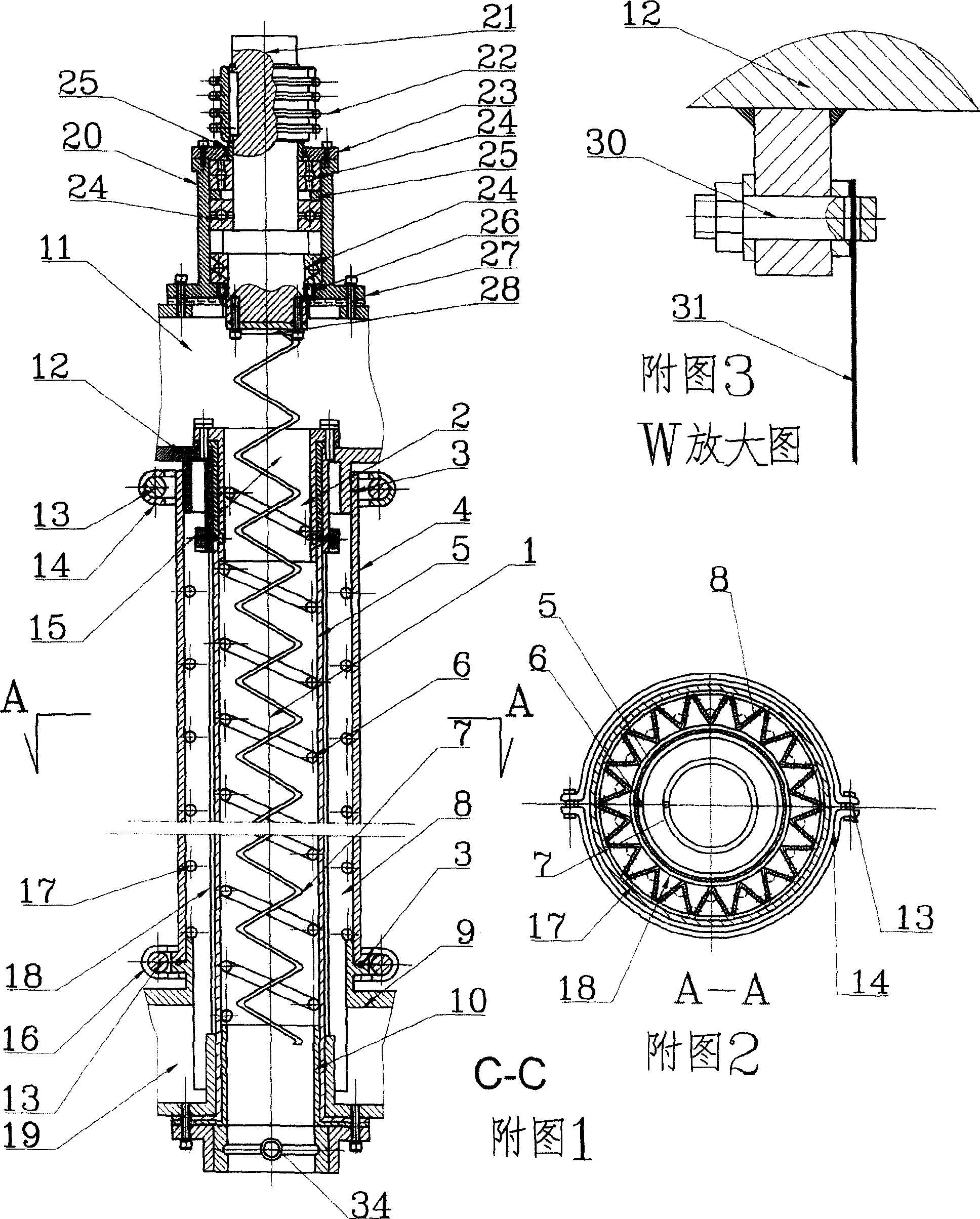

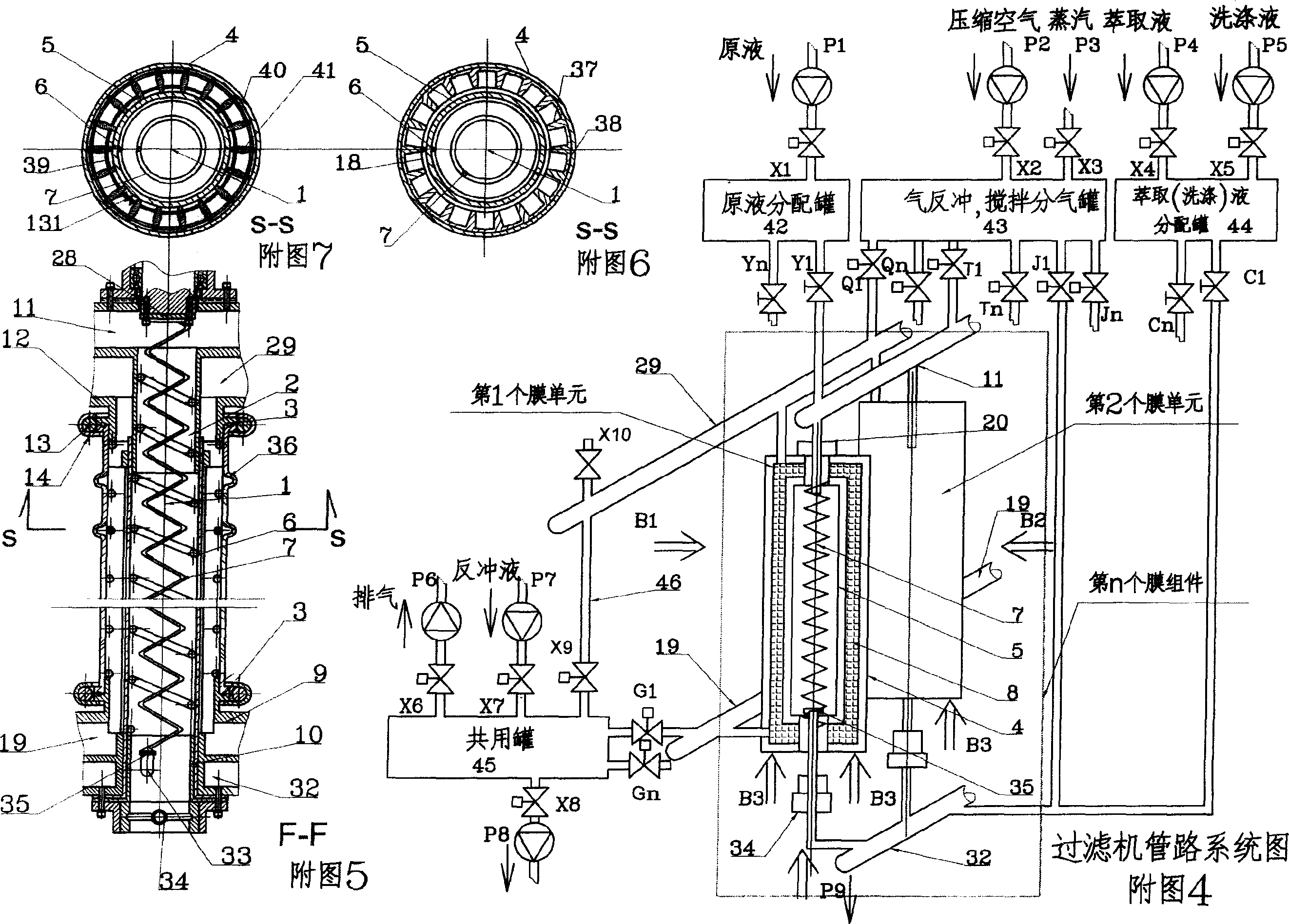

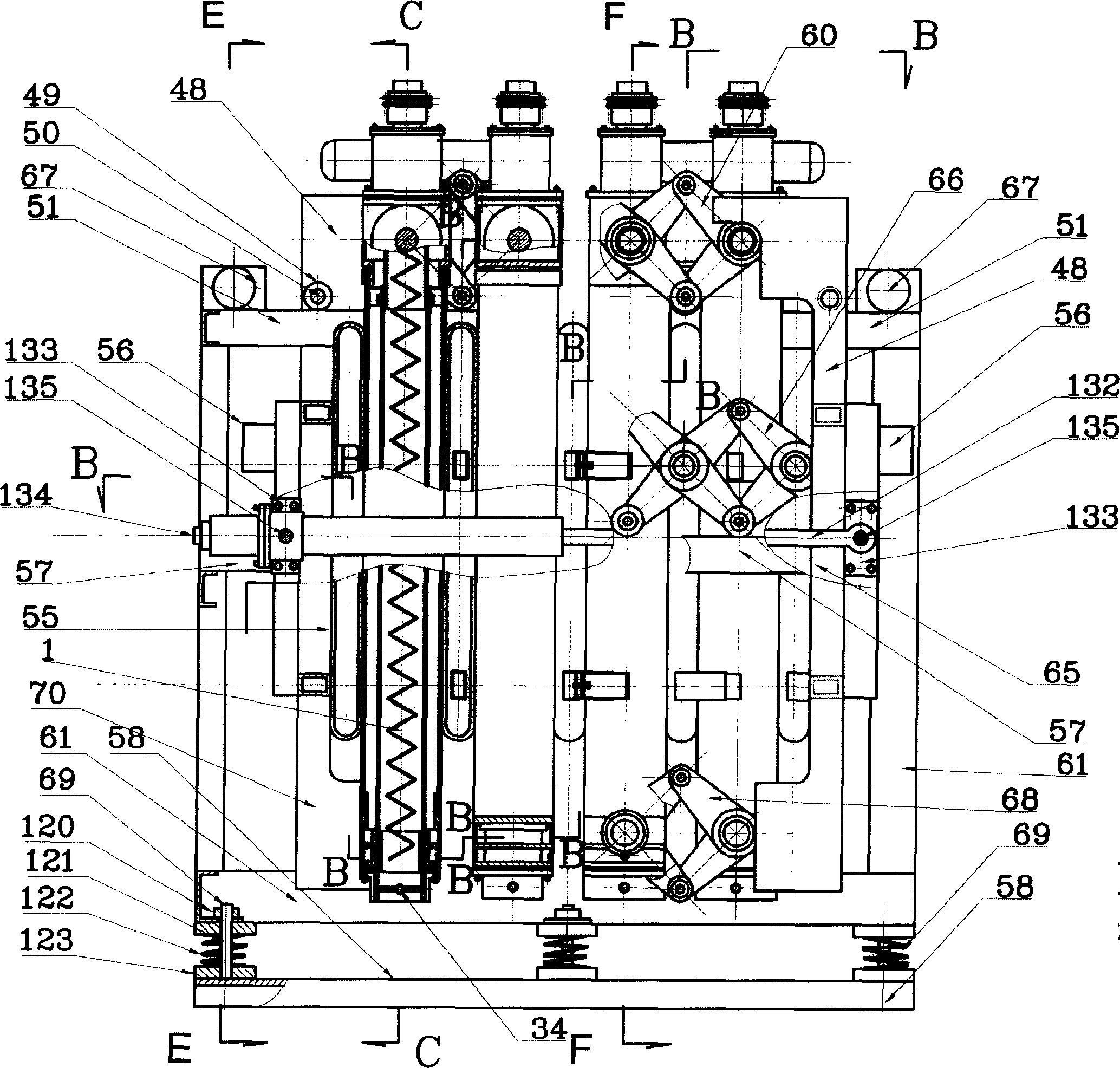

[0070] The filter of the present invention will be further described below in conjunction with the accompanying drawings.

[0071] In FIGS. 1 , 2 and 9 , the membrane assembly 2 includes four membrane units 1 , an upper flange chamber 12 , a lower flange chamber 9 , a slag discharge valve assembly, a steel wire rope 31 and a fixing clip 30 . Membrane unit 1 includes the following flexible components: tubular filter membrane 5, tubular filter membrane support frame 6, tubular grid, tubular closed membrane 4, the centerlines of their major axes coincide and are perpendicular to the horizontal line. A tube filter membrane supporting frame 6 is set inside the tube filter, a tubular grid is set outside it, and a tubular sealing membrane 4 is set outside the tube grid, and the tubular sealing membrane 4 adopts non-leakage stainless steel thin-walled tubes. The tubular grid is composed of ribs 8 and two layers of skeletons 17 and 18. The ribs 8 are a rectangular plate folded into a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com