Filtration mechanism

The technology of a filter mechanism and filter barrel is applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc. It can solve the problems of inconvenient disassembly and cleaning of the filter screen, inability to operate continuously, cumbersome operation steps, etc., and achieve simple structure , easy operation and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

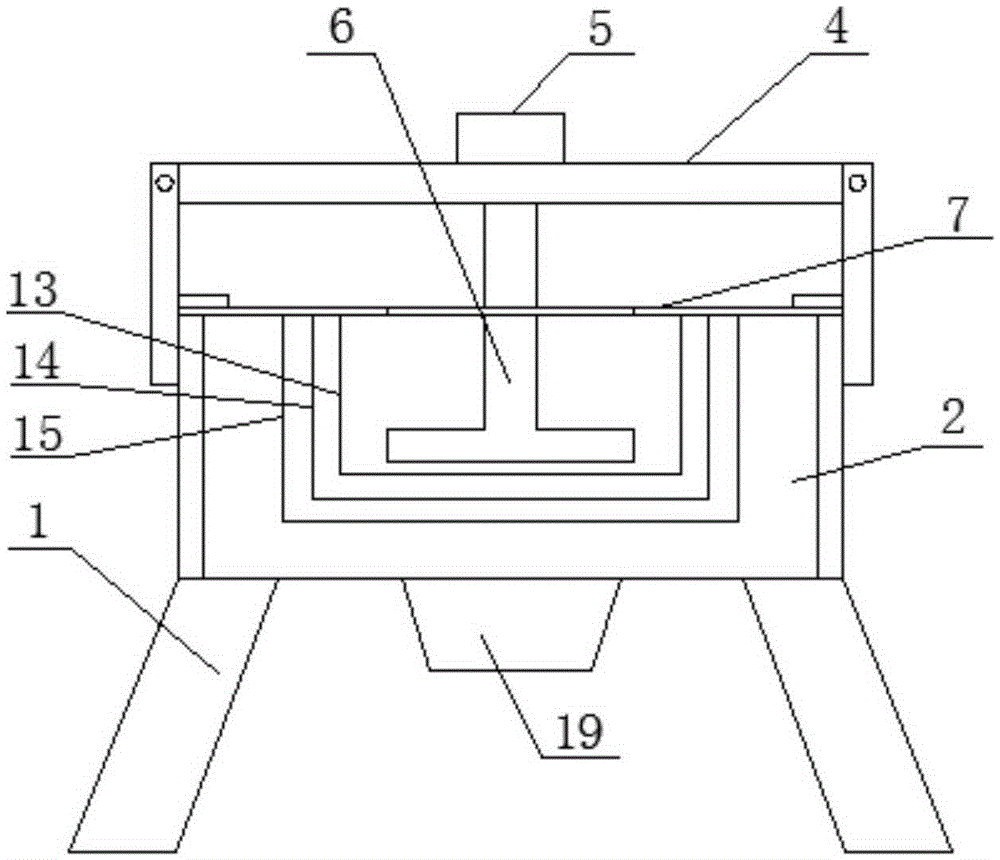

[0024] Such as Figure 1-7 As shown, a filter mechanism includes a support 1, a collection container 2 is arranged on the support 1, fixed grooves 3 are symmetrically arranged on both sides of the top of the collection container 2, and the two ends of the stirring support 4 are located in the fixed groove 3, The stirrer support 4 is provided with a motor 5, and the output end of the motor 5 is connected with a stirrer 6;

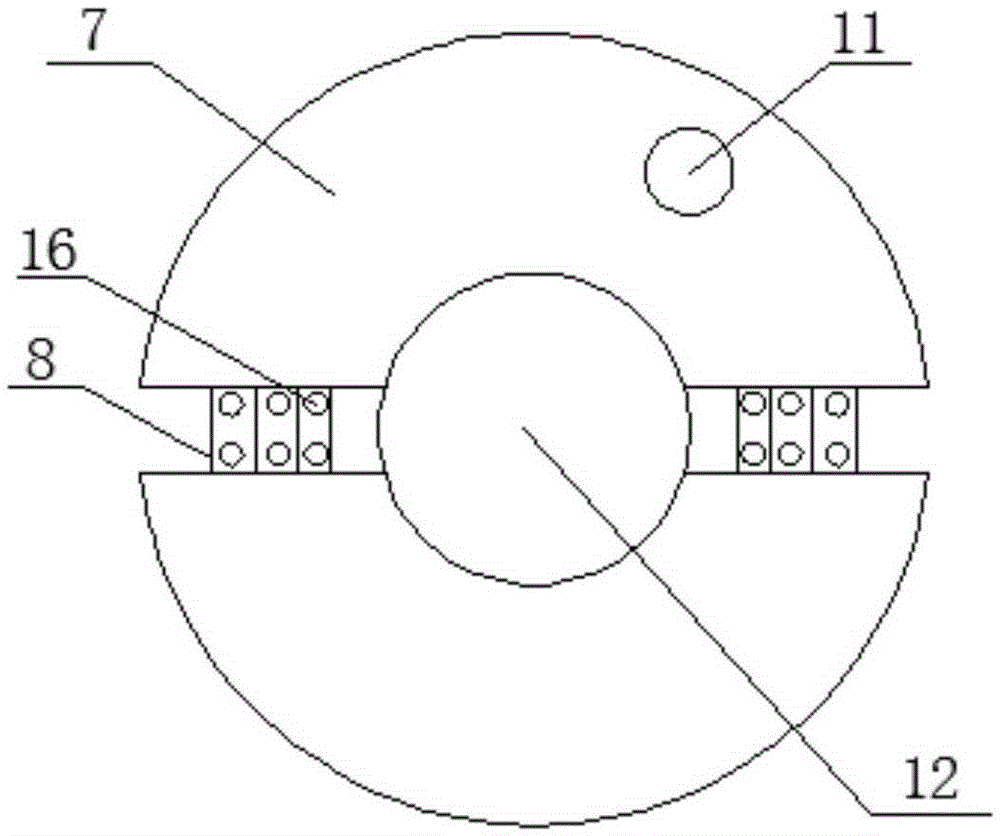

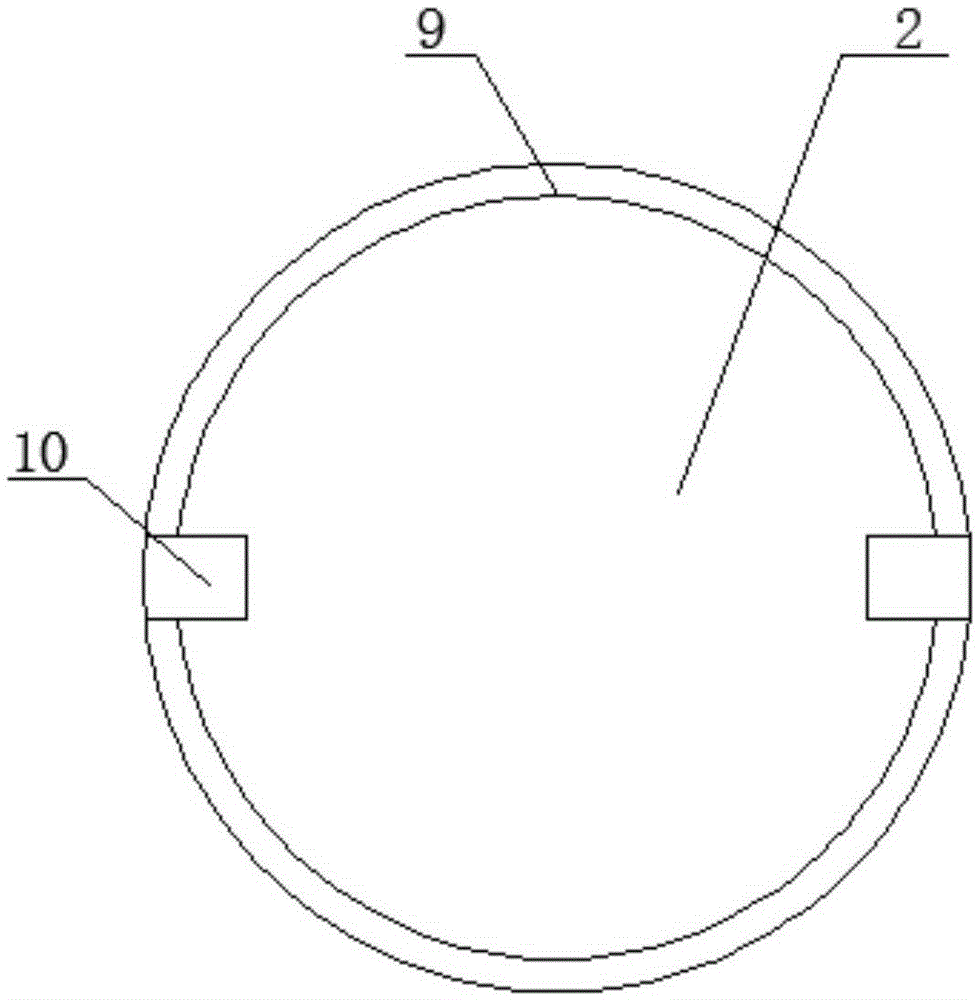

[0025] A filtering device is provided in the collecting container 2, and the filtering device includes a filtering bracket 7, which is detachably fixed in the collecting container 2, and a gap 8 is arranged on both sides of the filtering bracket 7, and a gap 8 is arranged on the inner wall of the collecting container 2. Limiting groove 9, two protrusions 10 are arranged symmetrically on the limiting groove 9, the gap 8 is located on the protrusions 10, a liquid inlet 11 is provided on the filter holder 7, a circular hole 12 is provided in the center of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com