Aluminum oxide ceramic integrated hot-pressing molding machine and working method

An alumina ceramic and molding machine technology, applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problem of poor alumina powder distribution casting molding quality, unreasonable temperature field distribution of heating devices, and inability to accurately control molding temperature and other issues, to achieve the effect of improving temperature field distribution, small processing allowance, and small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

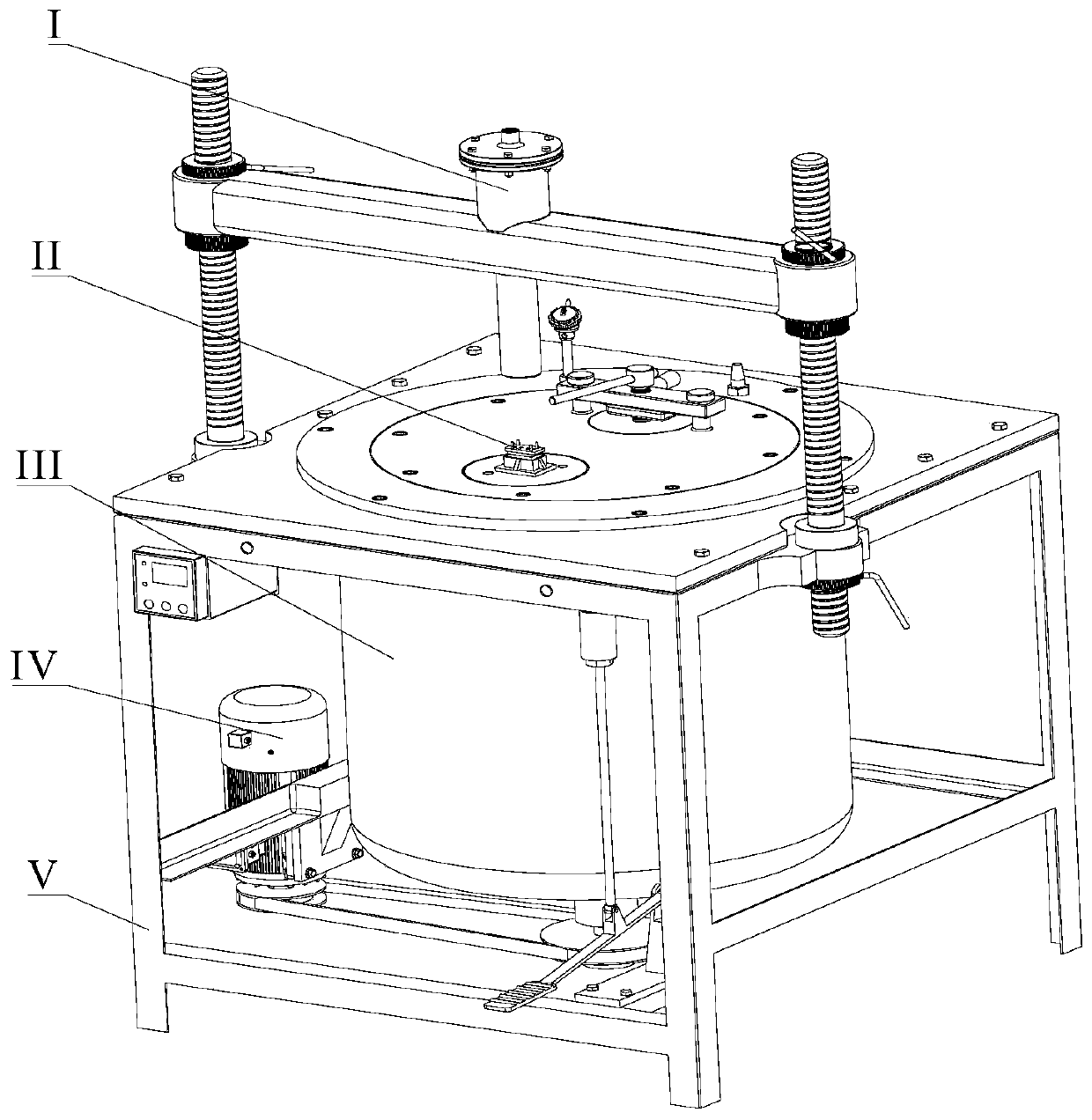

[0096] Attached below figure 1 - attached Figure 35 (b) A kind of aluminum oxide ceramic integrated hot press forming machine disclosed in this embodiment is further described;

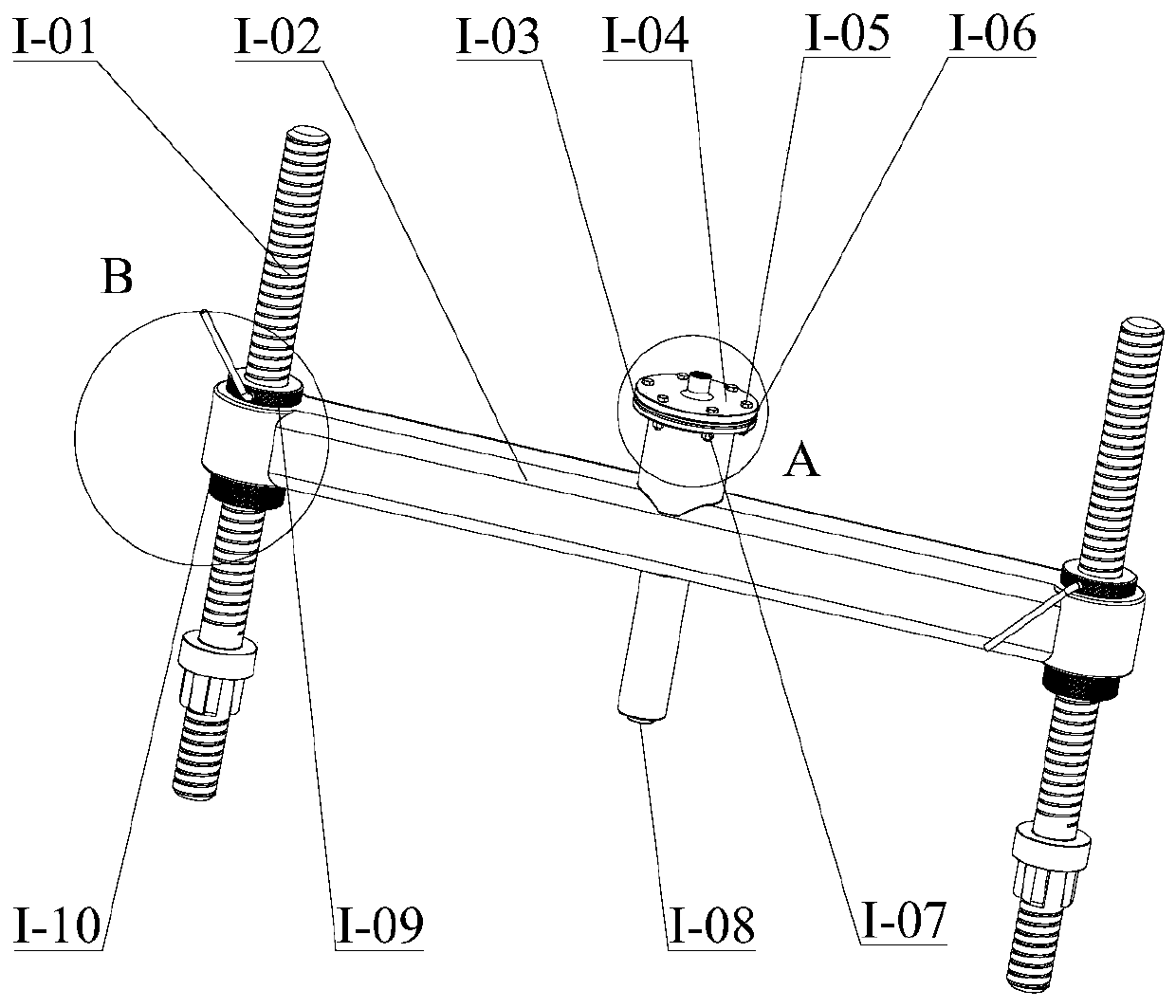

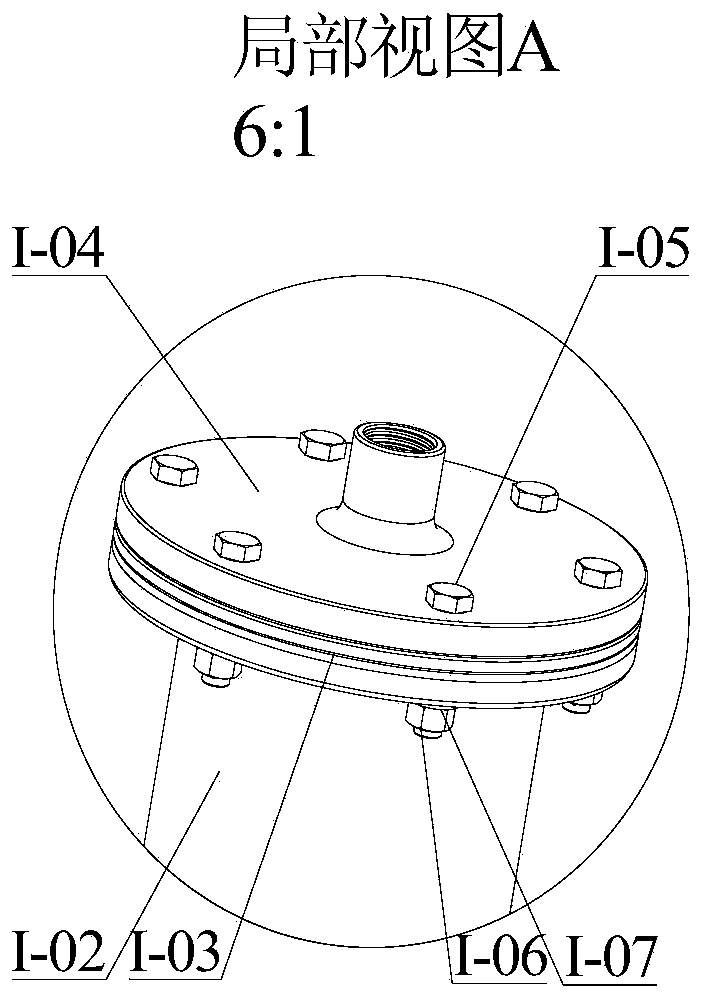

[0097] Such as figure 1As shown, an alumina ceramic integrated hot-press molding machine is composed of five parts: compacting device I, hot-pressing mold II, hot-pressing device III, stirring device IV and frame V. The chuck I-0101 on the -01 is positioned on the threaded support rod base V-03 on the frame V, and the clamping device I is fixed on the frame V by turning the clamping nut I-09. I-02 piston pressure rod stroke cavity I-0204 inner piston pressure rod I-08 is facing the center of the slurry outlet III-0504. The mold II is located in the mold nest III-06 on the hot pressing device III, and the slurry inlet II-0503 on the mold II located on the pulp inlet plate II-05 is grouted with the mold nest III-06 in the mold nest Port III-0601 is connected. The workbench positioning through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com