Drying machine

A dryer and hollow shaft technology, applied in the direction of non-progressive dryers, dryers, drying solid materials, etc., can solve problems such as waste of energy, and achieve the effects of reducing energy consumption, high thermal efficiency, and a wide range of materials to be processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

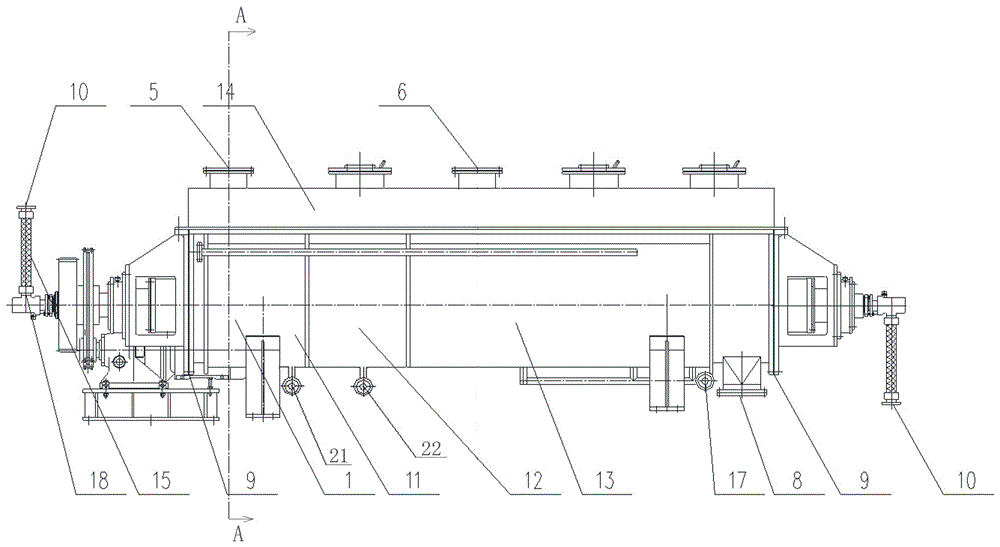

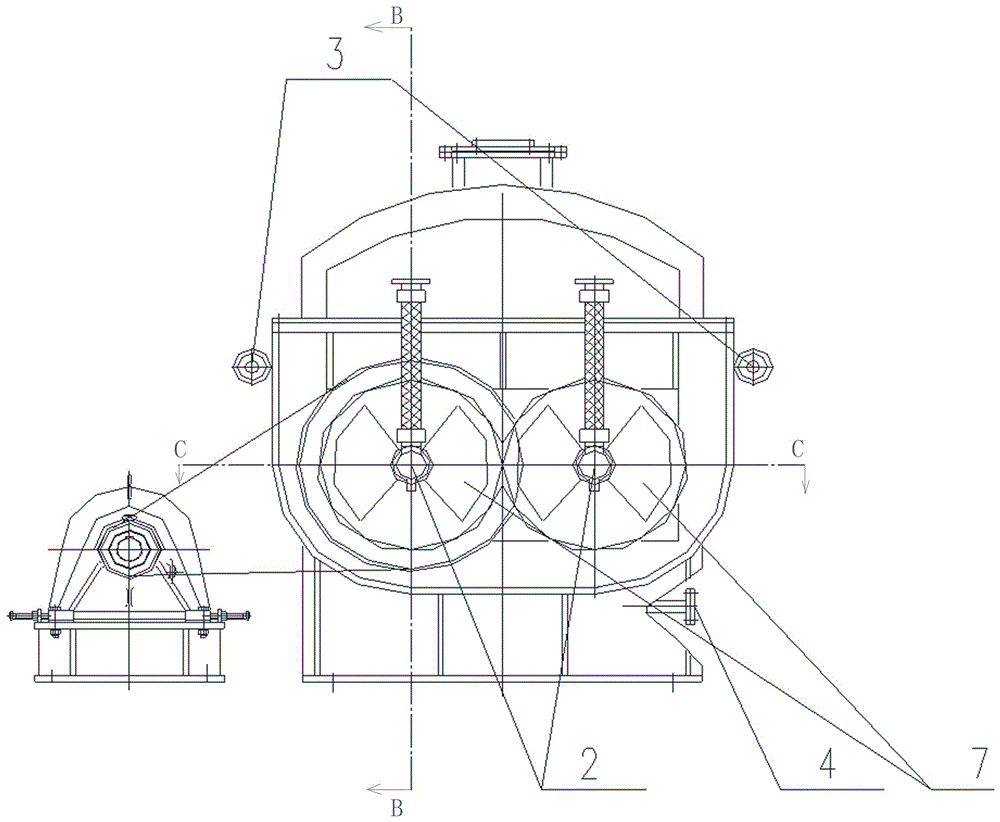

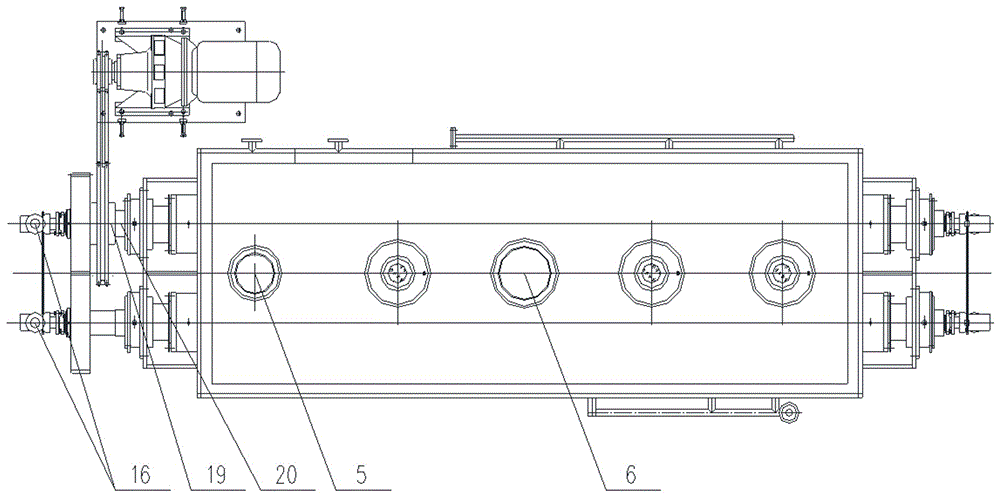

[0027] Such as figure 1 , figure 2 with image 3 As shown, the schematic diagrams of the front view, left view and top view of the dryer of the present invention are respectively provided. The dryer shown is composed of a housing 1, a hollow shaft 2, a steam inlet pipe 3, a hollow paddle 7, an end cover 9, The rotary joint 10, the heat carrier gas preheating section jacket 11, the steam condensate water preheating section jacket 12, the steam heating section jacket 13 and the driving device, the inside of the housing 1 shown is used for storing the material to be dried Cavity, the upper side of the front end of the housing 1 is provided with a material feeding port 5 communicating with the inner cavity, and an auger feeder can be connected above the material feeding port 5 to realize uniform feeding and feeding speed control. The lower side of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com