Bioreactor and bioreaction system with the bioreactor

A bioreactor, biomechanical technology, applied in the field of tissue engineering, can solve the problems of low integration, simultaneous realization of pulsatile perfusion and mechanical excitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

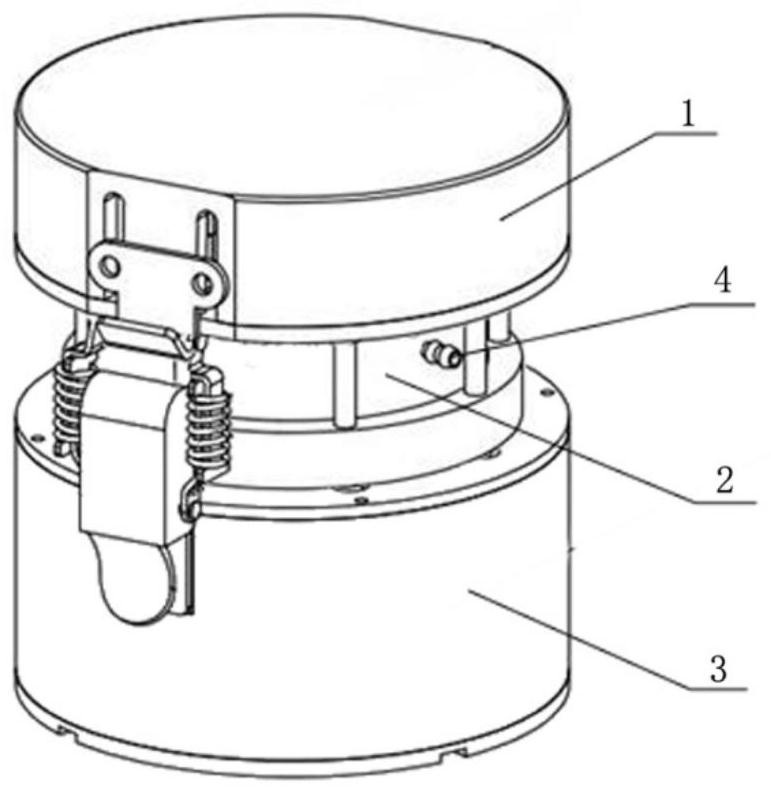

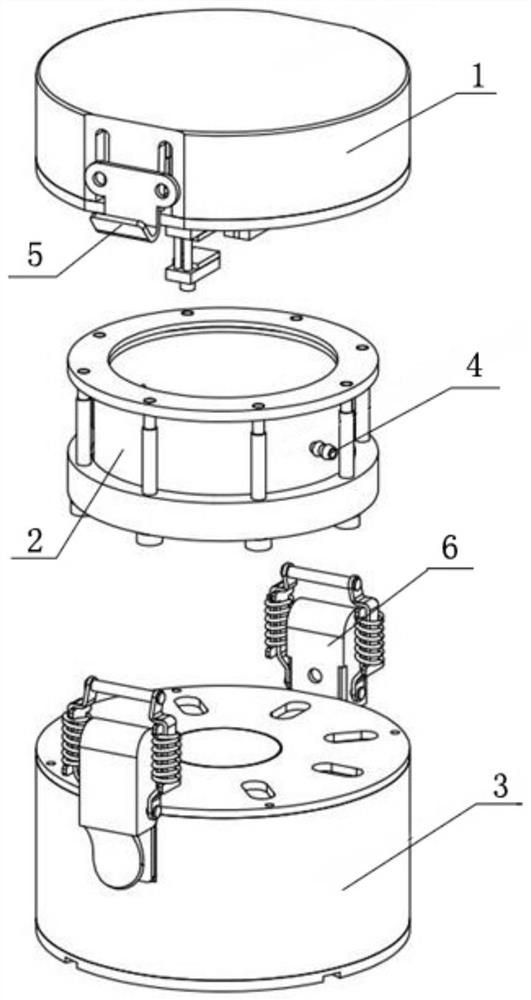

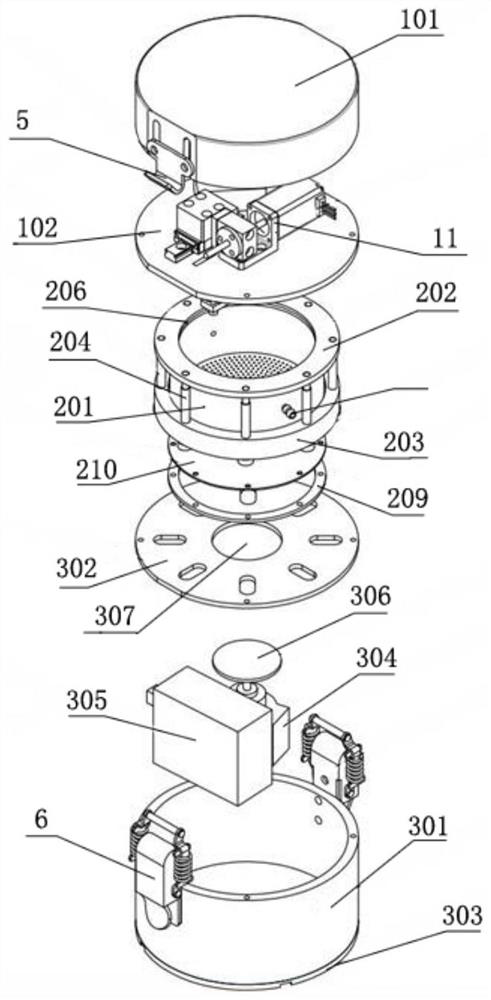

[0034] Such as Figure 1 to Figure 3 As shown, a bioreactor, which includes a mechanical generation chamber 1, a circulation culture chamber 2, and a pulsating flow generation chamber 3 that are detachably connected in sequence from top to bottom, and the bottom of the circulation culture chamber 2 and the pulsation flow generation chamber Inside the chamber 3 is provided a pulsating flow generating device for providing a physiological pulsating flow physiological environment for the tissue to be cultured, and the side wall of the circulation culture chamber 2 is provided with a culture solution inlet 4 and a culture solution outlet for the culture solution to enter and exit. In this way, the mechanical generation chamber 1 can simulate the biomechanical environment required by the muscle tissue when cultivating the muscle tissue; the circulation culture chamber 2 is used as a general dynamic culture, and the culture fluid inlet 4 and the culture fluid outlet are connected with...

Embodiment 2

[0045] This embodiment is similar to Embodiment 1, the difference is that, as Figure 9 As shown, the mechanical generating chamber 1 is a stirring mechanical generating chamber 1, and a stirring module is arranged inside the stirring mechanical generating chamber 1, and the stirring module extends into the circulation through the bottom of the stirring mechanical generating chamber 1. The interior of culture room 2.

[0046] Such as Figure 9As shown, the stirring mechanism generation chamber 1 includes a first top cover 101, and the stirring module includes a first bottom plate 102 arranged at the bottom of the first top cover 101, and is arranged on the first bottom plate 102 close to the first bottom plate 102. The second stepper motor 130 on the side of a top cover 101 and the second control board 131 connected thereto, the output end of the second stepper motor 130 is provided with a connecting bar 132, and the connecting bar 132 passes through The first bottom plate 1...

Embodiment 3

[0049] like Figure 10 Shown, a kind of bioreaction system, wherein, comprises bioreactor 7, peristaltic pump 8 and liquid storage bottle 9, and described bioreactor 7, peristaltic pump 8 and liquid storage bottle 9 are connected end-to-end through pipeline to form circulation loop , the bioreactor 7 is the bioreactor 7 described in embodiment 1, the pipelines on both sides of the bioreactor 7 are respectively connected to the culture solution inlet 4 and the culture solution outlet on the side wall of the circulation culture chamber 2 connect. The culture is placed in the bioreactor 7, and the culture solution in the pipeline driven by the peristaltic pump 8 flows through the bioreactor 7, and the culture solution is housed in the liquid storage bottle 9, which is used to update the culture solution and belt in the bioreactor 7. Take away the waste produced by cultivation.

[0050] The working principle of this embodiment: the liquid storage bottle 9 is loaded with culture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com