The connection structure of the louver type barrier

A technology for connecting structures and louvers, applied in the directions of roads, roads, buildings, etc., can solve the problems of affecting the effect of louver components, many components required for installation, and unfavorable installation efficiency, etc., and achieves ingenious structure, simplified installation difficulty, and simple installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

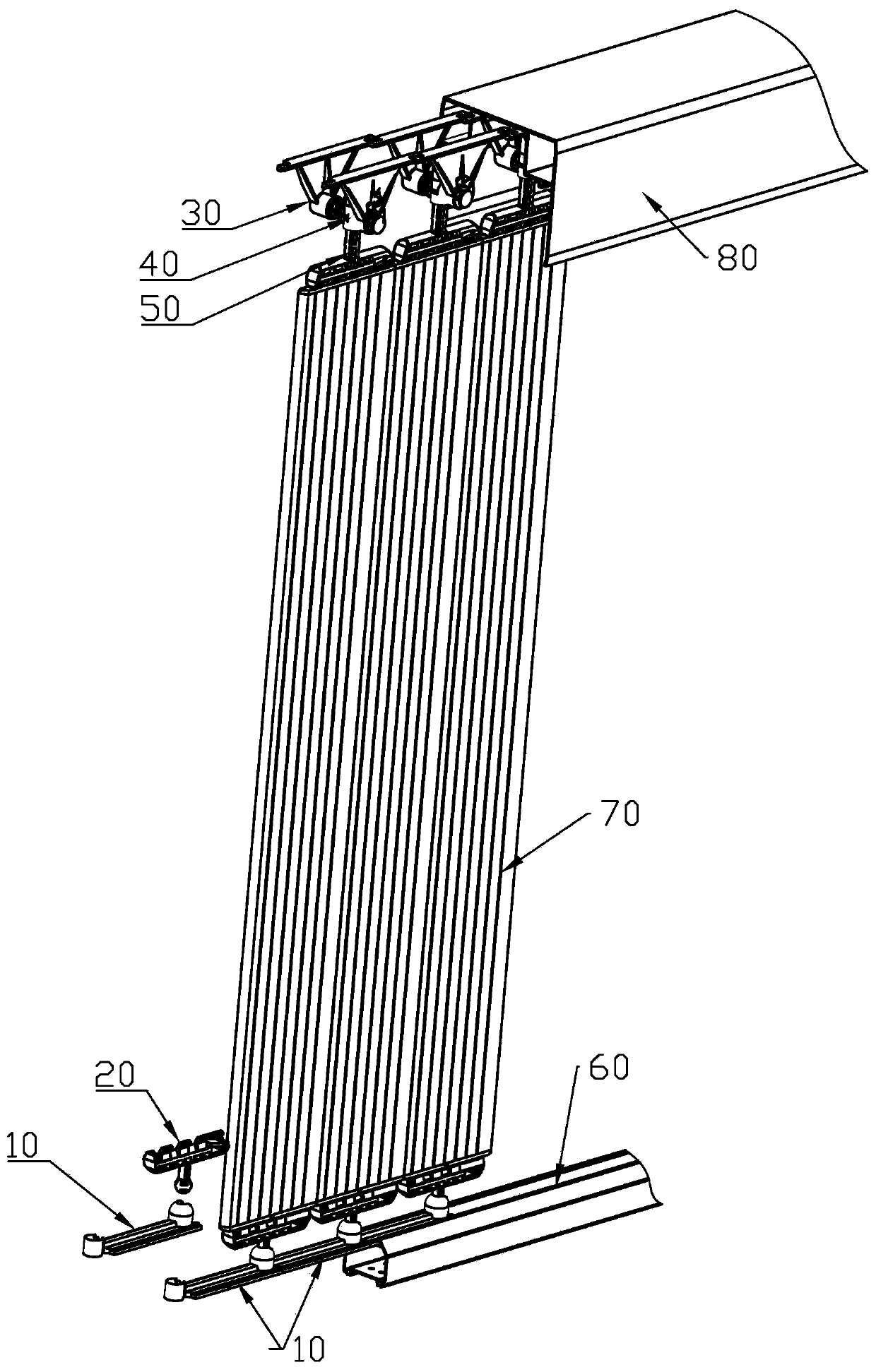

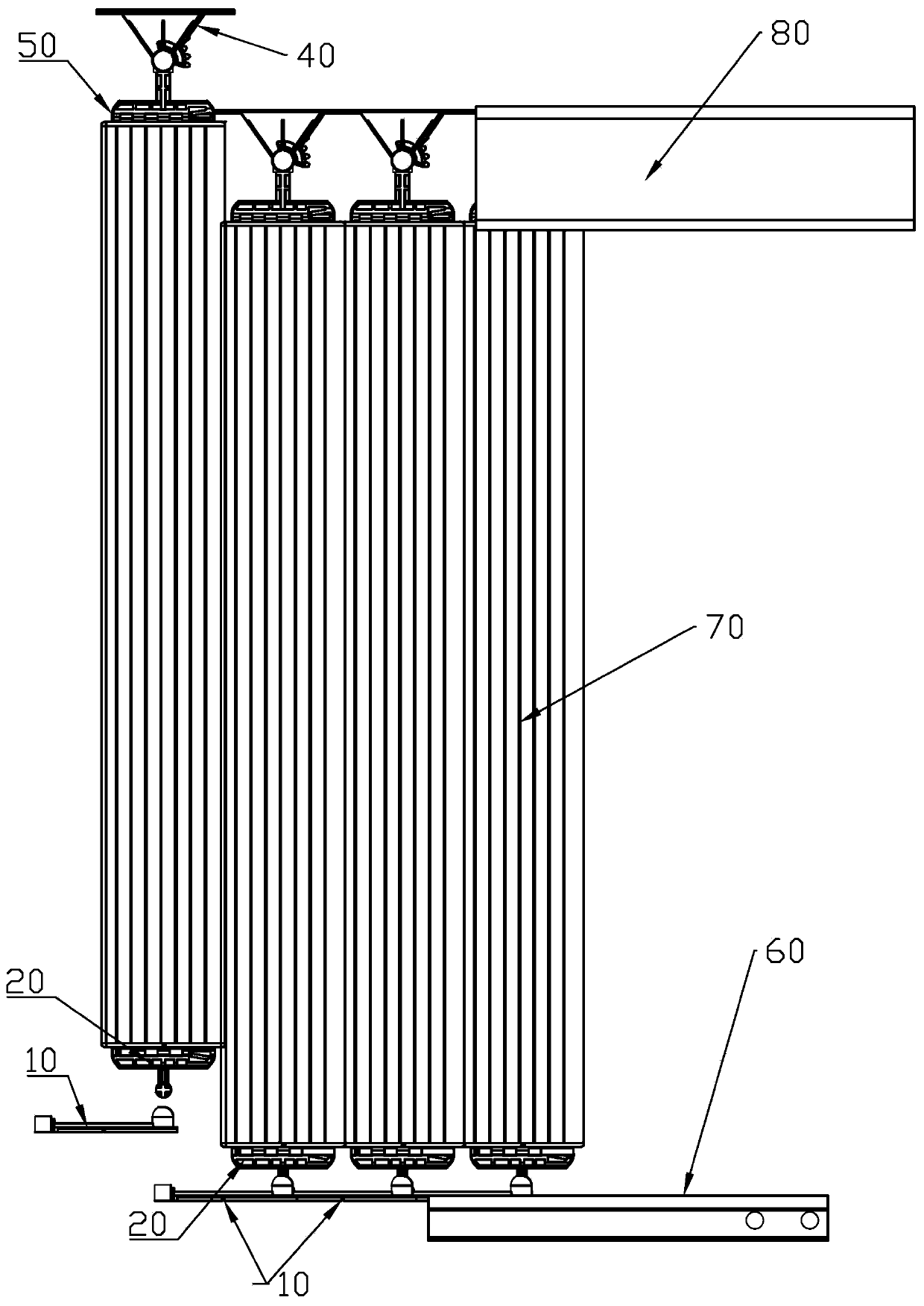

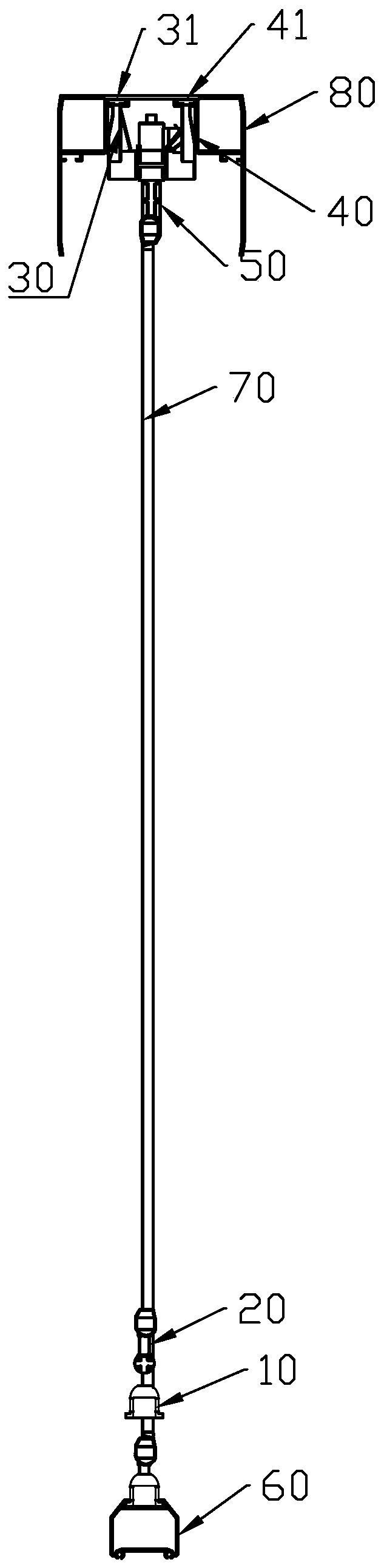

[0028] like Figure 1 to Figure 11 As shown, the main point of the connection structure of the louver-type barrier gate of the present invention is that it is connected to the beam through a single part that can be inlaid from the end to the end, so that not only can the parts required for installation be reduced, the installation difficulty is simplified, and the inlay from the end to the end It can also ensure that the distance between the installed louver blade assemblies 70 remains constant, ensuring the consistency of installation.

[0029] like Figure 1 ~ Figure 3 As shown, the connection structure of the louver type barrier of the present invention includes the connection structure of the upper beam 80 and the connection structure of the lower beam 60 . In this embodiment, the connecting structure of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com