Counter-rotating bladeless stirring device and method

A stirring device and counter-rotating technology, applied in chemical instruments and methods, transportation and packaging, dissolving and other directions, can solve the problems such as the inability to achieve continuous and stable operation of the device, the complex structure of the mechanical stirring device, and the easy damage to the seal and other structures. Simple structure, low cost, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

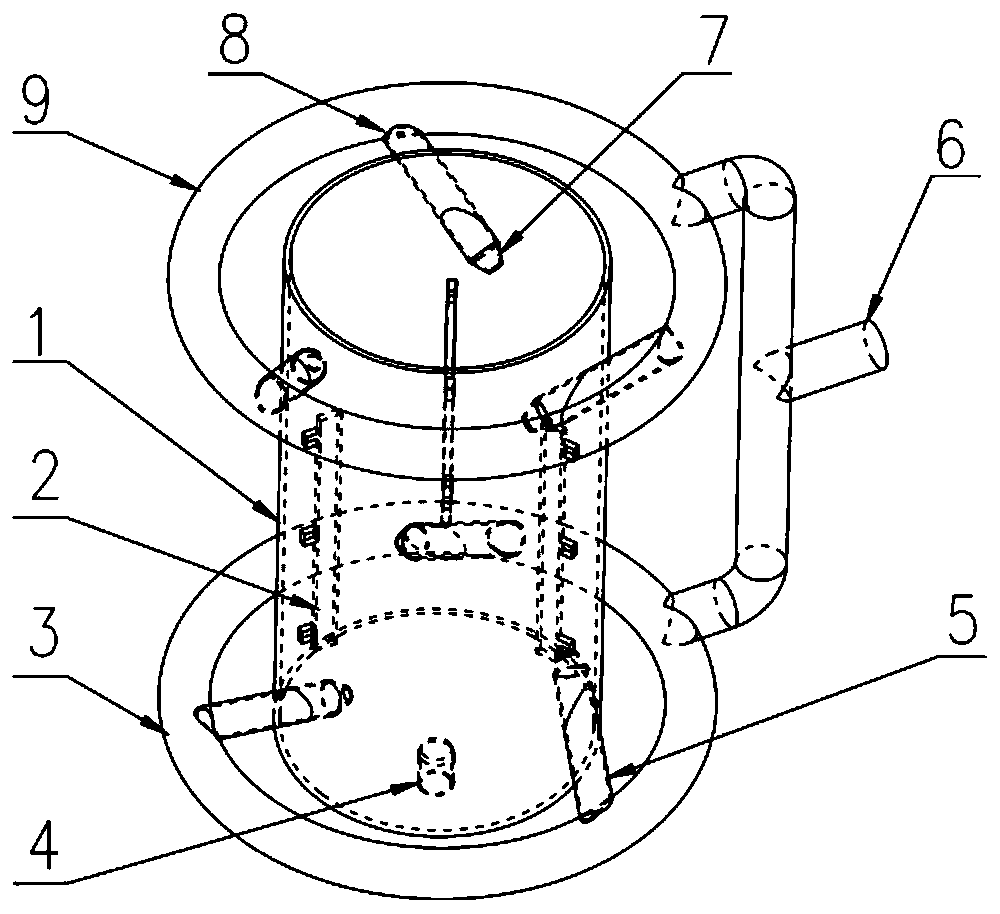

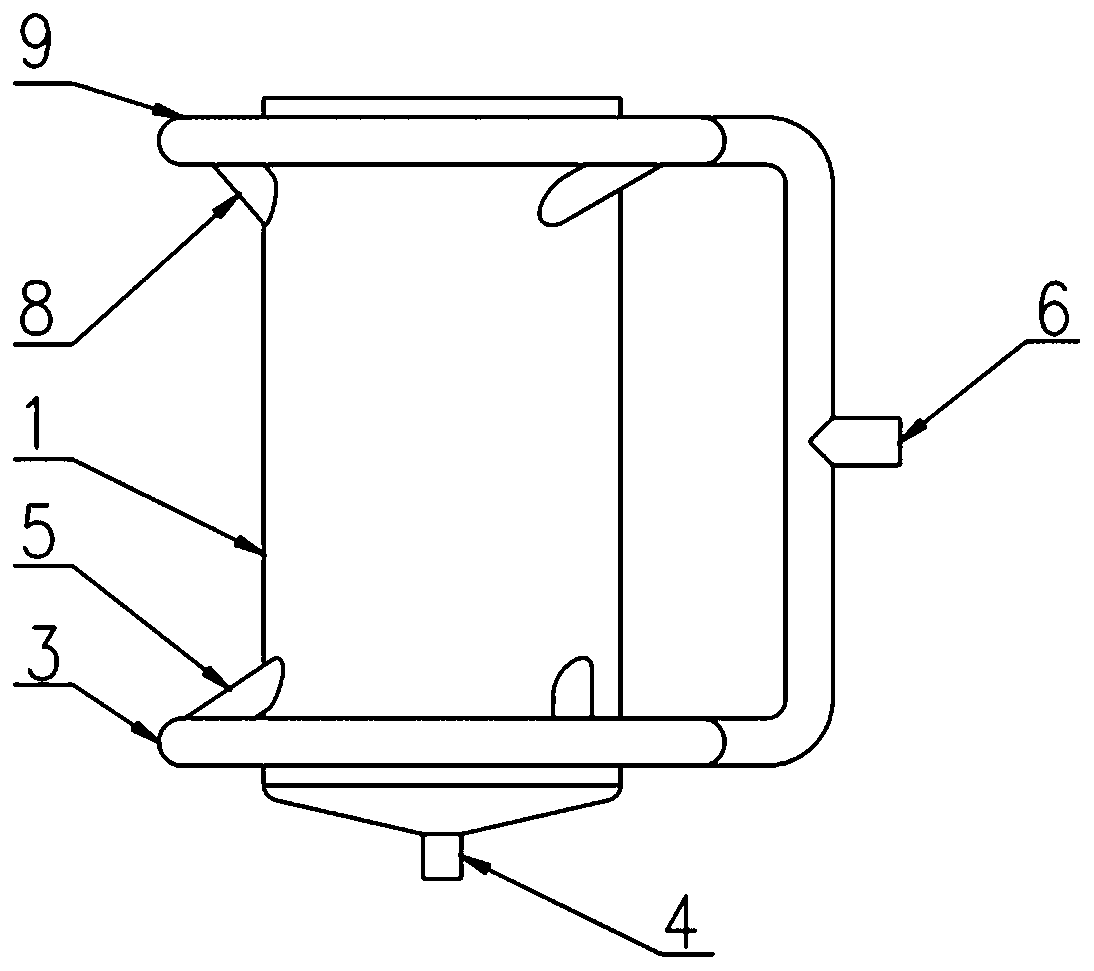

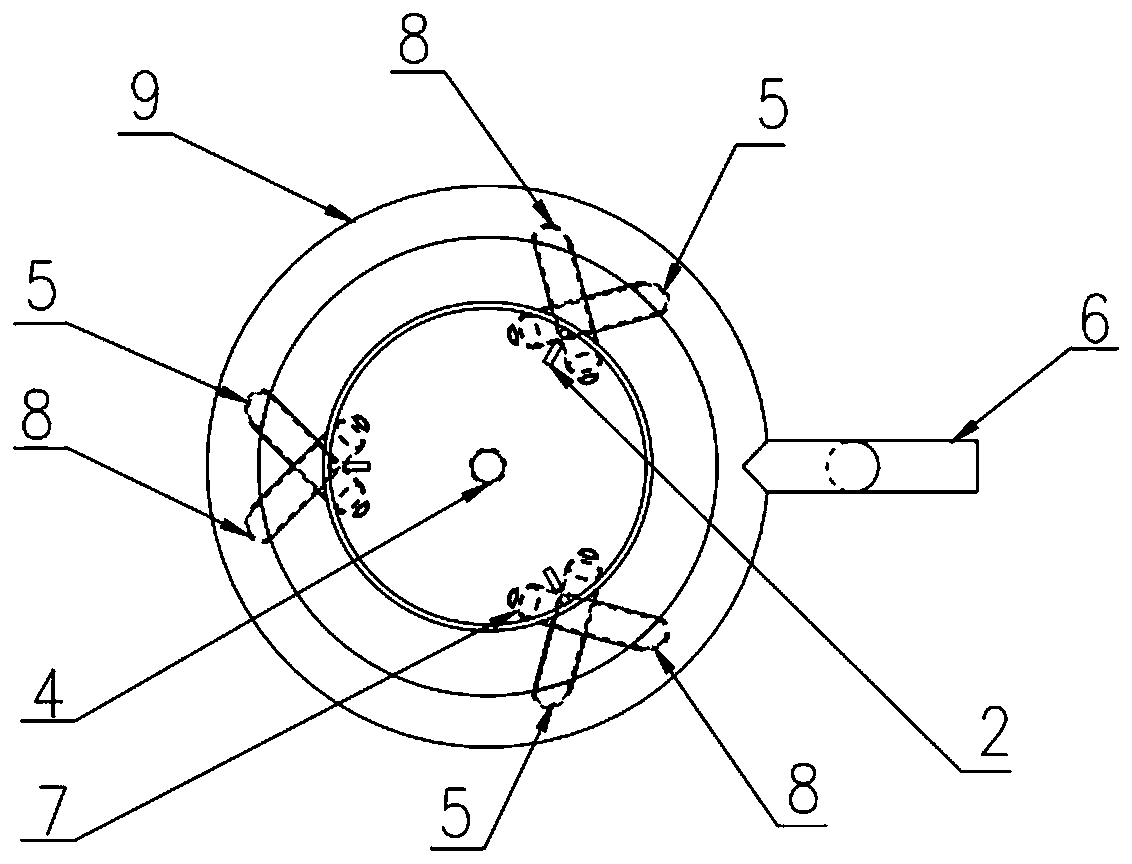

[0024] Such as figure 1 , figure 2 and image 3 As shown, the counter-rotating bladeless stirring device of the present invention is characterized in that: it includes a columnar structure cylinder 1 and a stirring mixing device, the cylinder 1 is provided with a discharge port 4 of a funnel structure, and the cylinder 1 inner wall surface There are three vertically arranged baffles 2 evenly distributed, and the top of the cylinder body 1 is respectively provided with a feeding port 10 and a chemical feeding port 11. The whole device is completely closed and does not allow the slurry to splash outward;

[0025] The stirring and mixing device includes a lower distribution ring 3 and an upper distribution ring 9 arranged around the outside of the cylinder body 1, the lower distribution ring 3 is arranged on the periphery below the cylinder body 1, and the upper distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com