Selectivity hydrodeolefin catalyst used for continuously reforming gasoline and preparation method thereof

A technology for reforming gasoline and catalysts, applied in refining to remove heteroatoms, etc., can solve problems such as not being able to meet long-term operation and short service life of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

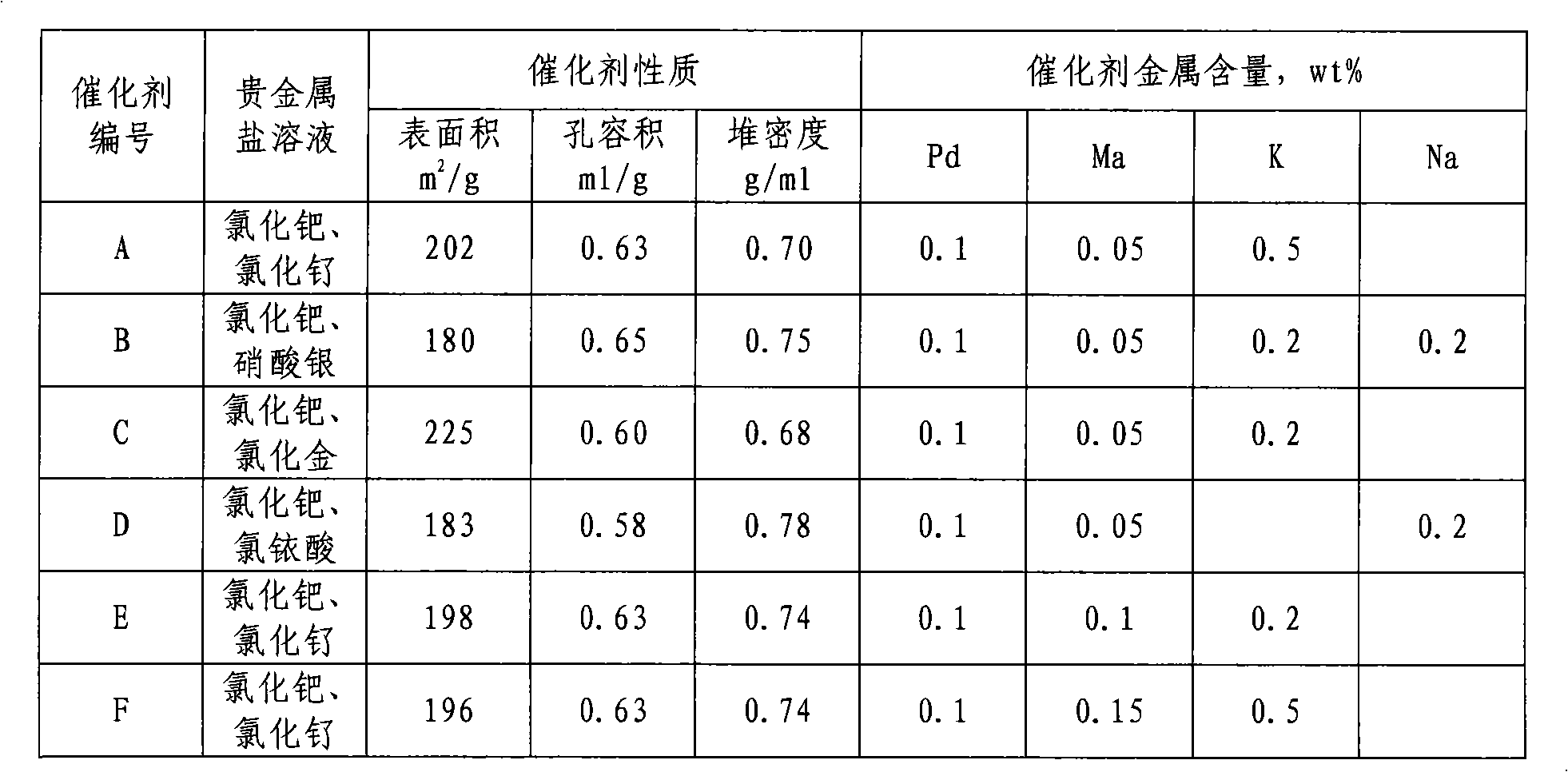

[0026] With shaped alumina as a carrier, in the presence of competitive adsorbent hydrochloric acid solution, use a Pd salt solution with a content of 0.1wt% (based on dry basis alumina), and the concentration of Ma is determined according to the final content of the catalyst in different molar ratios The catalyst of the present invention can be obtained by impregnating alumina carriers of different specifications, drying at 120°C for 8-12 hours, and roasting at 500°C in air for 4-6 hours. Table 1 lists the catalysts prepared by the method of the present invention.

[0027] Catalyst prepared by the present invention in table 1

[0028]

Embodiment 2

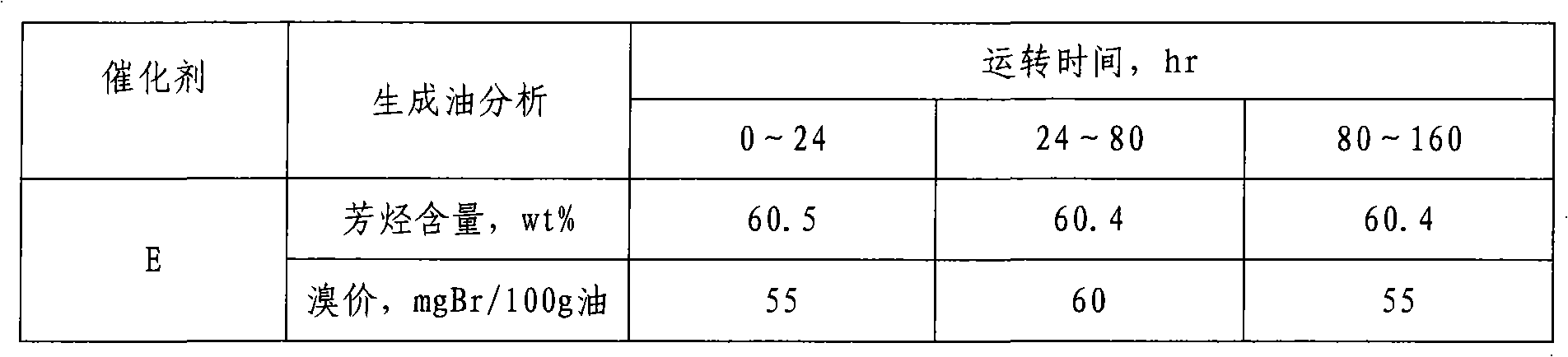

[0030] Using the catalyst in Example 1, a test of selective hydrodeolefination of continuously reformed gasoline was carried out on a 100 ml single-tube device. The raw material is the whole distillate of reformed gasoline from a continuous reforming unit, the distillation range is 26.2-218.2°C, the content of aromatics is 60.5wt%, and the bromine value is 3640mgBr / 100g oil. The reaction conditions are pressure 2.0MPa, reaction temperature 170°C, hydrogen-oil ratio 250:1, liquid hourly volume space velocity 4hr -1 , the catalyst was reduced in hydrogen at 170°C for 8 hours, and pre-sulfurized with dimethyl disulfide as a vulcanizing agent at 170°C. The vulcanization amount was 0.5wt% of the catalyst. The results are listed in Table 2.

[0031] Table 2 Hydrogenation results of continuous reforming full distillate gasoline

[0032] catalyst

Embodiment 3

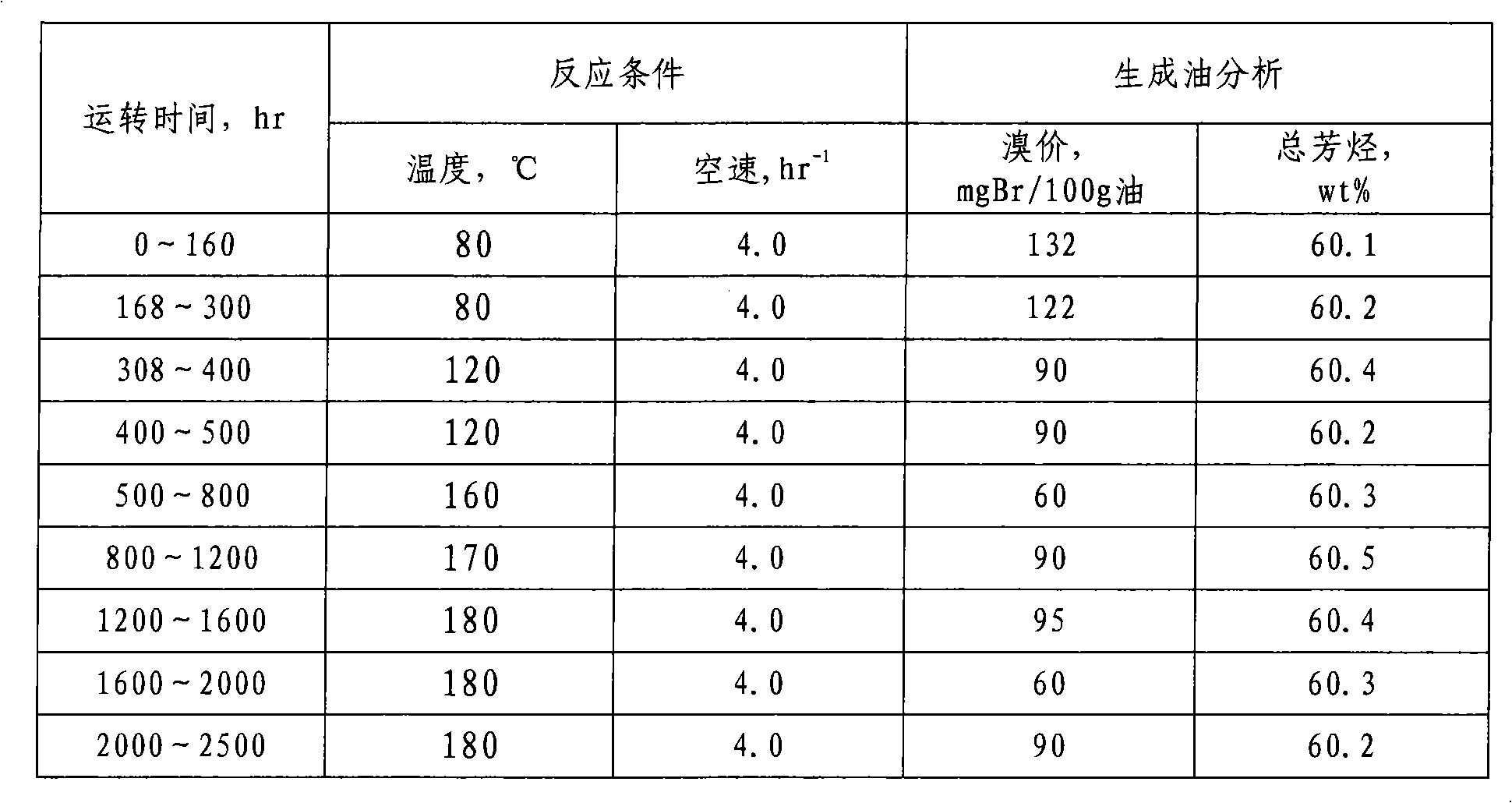

[0034] Using the catalyst E described in Example 1, a test of selective hydrodeolefination of continuously reformed gasoline was carried out on a 100 ml single-tube device. The raw material is the raw material oil in Example 2. The reaction conditions are pressure 2.0MPa, reaction temperature 170°C, hydrogen oil volume ratio 250:1, liquid hourly volume space velocity 4hr -1 . The catalyst is first reduced in hydrogen at 170°C for 8 hours. After the reduction is complete, the temperature is lowered to 60°C and then the feed is started. The reaction temperature is gradually increased by 10°C / hr each time, and then kept constant for 3 hours until the final reaction temperature reaches 170°C. , began to respond normally, and the results are listed in Table 3.

[0035] Table 3 Hydrogenation results of continuous reforming full distillate gasoline

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com