Organic EL element and method of manufacturing the same, organic EL display device using the element, organic EL material, and surface emission device and liquid crystal display device using the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

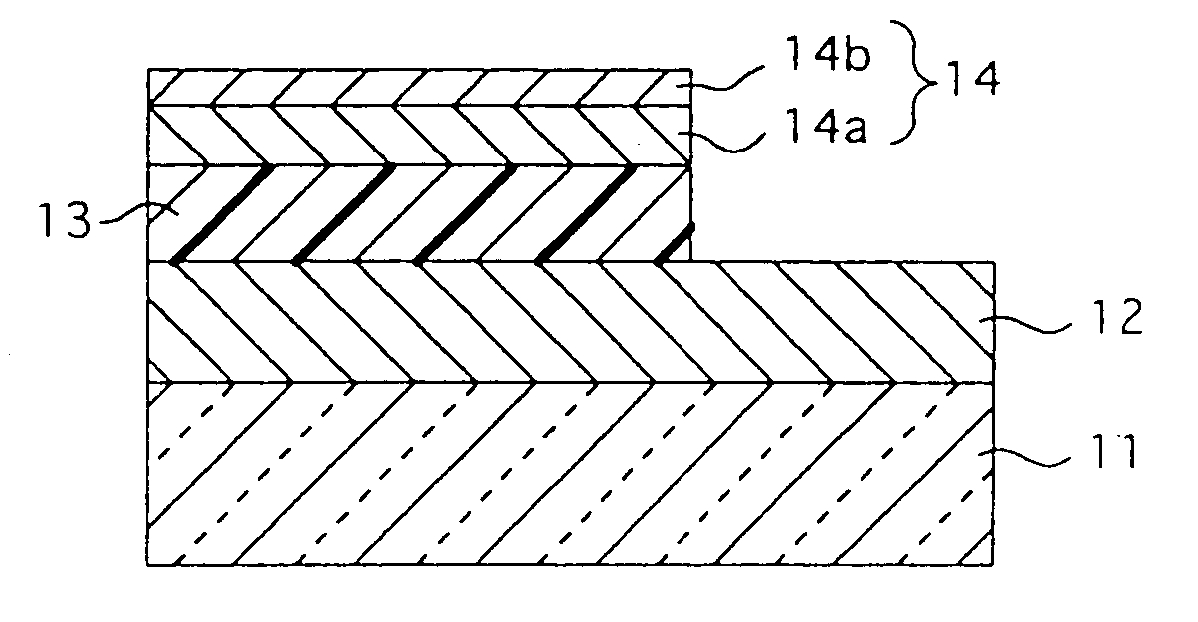

[0097]FIG. 1 is a sectional view showing an organic EL element according to a first embodiment of the present invention.

[0098] An ITO film of about 200 nm thickness is formed as an anode 12 on a glass substrate 11. Also, a poly[3-(4-alkylphenyl)thiophene] film of about 150 nm thickness is formed as an organic EL layer (a luminous layer) 13 in the predetermined area on the anode 12.

[0099] In addition, a laminated film having the double-layered structure consisting of a first conductive film 14a made of the conductor containing Mg and a second conductive film 14b made of the conductor containing Ru is formed as a cathode 14 on the organic EL layer 13. In this example, a thickness of the first conductive film 14a is about 100 nm, and a thickness of the second conductive film 14b is about 50 nm.

[0100] The anode 12 is not limited to ITO, and any conductor having the large work function may be employed. In this case, if the light is irradiated to the substrate 11 side, the anode 12 mus...

second embodiment

[0118]FIGS. 4A to 4D are sectional views showing a method of manufacturing an organic EL element according to a second embodiment of the present invention.

[0119] The second embodiment shows an example of the organic EL element in which the buffer layer is provided between the anode and the organic EL layer.

[0120] First, as shown in FIG. 4A, the ITO film of 200 nm thickness is formed on an upper side of a glass substrate 21 by the sputter method to construct an anode (lower electrode) 22.

[0121] Then, as shown in FIG. 4B, the Ru (ruthenium) film of 30 nm thickness is formed on the anode 22 by the sputter method to construct a buffer layer 23. Then, as shown in FIG. 4C, the short-time annealing (RTA) is carried out at the temperature of 700° C. for 3 to 5 seconds by using the RTA (Rapid Thermal Annealing) equipment that heats by the lamp.

[0122] The Ru on the surface of the buffer layer 23 is oxidized by this short-time annealing. In this case, since RuO can be generated in a very s...

third embodiment

[0137]FIGS. 5A to 5D are plan views showing manufacturing steps of an organic EL display device according to a third embodiment of the present invention.

[0138] This third embodiment shows an example of a method of manufacturing the full-color organic EL display device.

[0139] First, as shown in FIG. 5A, an ITO film of about 200 nm thickness is formed by sputtering ITO on the overall upper surface of a glass substrate 31. Then, anodes (lower electrodes) 32 are formed by patterning the ITO film into a stripe shape by virtue of the photolithography. In this case, a width of the anode 32 is set to 20 μm, for example.

[0140] Then, an EL emission layer 33 is formed by forming poly[3-(4-alkylphenyl)thiophene] on the overall display area of the glass substrate 31 by virtue of the spin coating method to have a thickness of 1500 Å.

[0141] In the present invention, the material of the EL emission layer 33 is not limited to poly[3-(4-alkylphenyl) thiophene]. But such EL emission layer 33 must ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com