Load type metal mesoporous molecular sieve noble metal catalyst and preparation method thereof

A technology of noble metal catalysts and mesoporous molecular sieves, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems affecting the dispersion of catalyst active components, the limited number of hydroxyl groups on the surface of the carrier, and the migration and aggregation of metal particles And other problems, to achieve the effect of uniform size, avoid aggregation, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

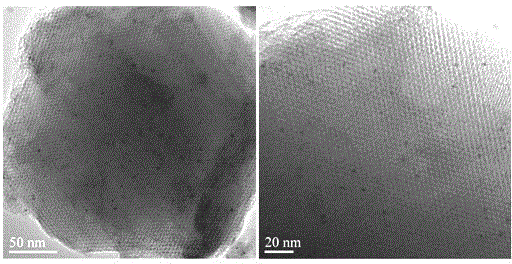

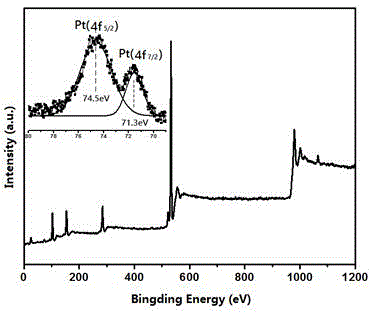

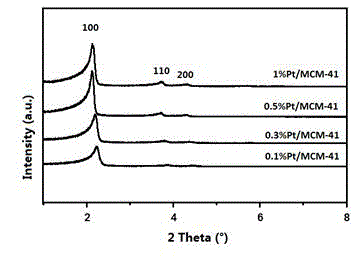

[0025] Weigh 2.34 g of cetyltrimethylammonium bromide into 100 ml of deionized water, and stir to dissolve it. Weigh 0.0707g of potassium chloroplatinate and dissolve it in heated deionized water. After clarification, add it dropwise to the transparent cetyltrimethylammonium bromide solution, stir to form a stable sol system, and then add 1mL Dilute hydrochloric acid with a mass fraction of 10% continued to stir for 1 hour, then added 10 mL of tetraethyl orthosilicate dropwise, continued to stir for 2 hours to be uniformly hydrolyzed, and then adjusted the pH to 10-11 with 25% concentrated ammonia water. The molar ratio of minutes is 1 TEOS : 0.144 CTAB : 4.0NH 3 : 149.5 H 2 O, followed by continuous stirring for 6 h, then transferred to a polytetrafluoroethylene-lined reaction tank, and crystallized at 110 °C for 2 days. After the crystallization, it was cooled to room temperature, filtered with suction, washed until the pH of the filtrate was 7, and dried at 110 °C for 12...

Embodiment 2

[0027] Weigh 2.34 g of cetyltrimethylammonium bromide into 100 ml of deionized water, and stir to dissolve it. Weigh 0.0348g of potassium chloroplatinate and dissolve it in heated deionized water. After clarification, add it dropwise to the transparent cetyltrimethylammonium bromide solution, stir to form a stable sol system, and then add 1mL Dilute hydrochloric acid with a mass fraction of 10% continued to stir for 1 hour, then added 10 mL of tetraethyl orthosilicate dropwise, continued to stir for 2 hours to be uniformly hydrolyzed, and then adjusted the pH to 10-11 with 25% concentrated ammonia water. The molar ratio of minutes is 1 TEOS : 0.144 CTAB : 4.0NH 3 : 149.5 H 2 O, followed by continuous stirring for 6 h, then transferred to a polytetrafluoroethylene-lined reaction tank, and crystallized at 110 °C for 2 days. After the crystallization, it was cooled to room temperature, filtered with suction, washed until the pH of the filtrate was 7, and dried at 110 °C for 12...

Embodiment 3

[0029] Weigh 2.34 g of cetyltrimethylammonium bromide into 100 ml of deionized water, and stir to dissolve it. Weigh 0.0202g of potassium chloroplatinate and dissolve it in heated deionized water. After clarification, add it dropwise to the transparent cetyltrimethylammonium bromide solution, stir to form a stable sol system, and then add 1mL Dilute hydrochloric acid with a mass fraction of 10% continued to stir for 1 hour, then added 10 mL of tetraethyl orthosilicate dropwise, continued to stir for 2 hours to be uniformly hydrolyzed, and then adjusted the pH to 10-11 with 25% concentrated ammonia water. The molar ratio of minutes is 1 TEOS : 0.144 CTAB : 4.0NH 3 : 149.5 H 2 O, followed by continuous stirring for 6 h, then transferred to a polytetrafluoroethylene-lined reaction tank, and crystallized at 110 °C for 2 days. After the crystallization, it was cooled to room temperature, filtered with suction, washed until the pH of the filtrate was 7, and dried at 110 °C for 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com