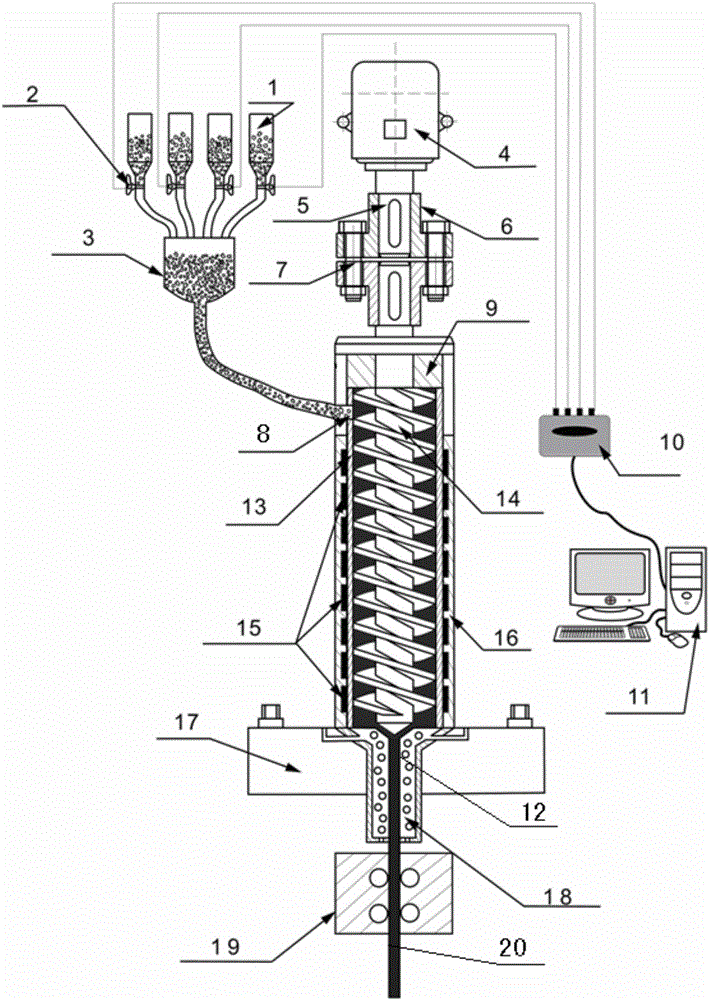

Device for high-throughput preparation of multi-component gradient metal materials

A metal material and multi-component technology, applied in the preparation of test samples, additive processing, etc., can solve the problems of long cycle, low efficiency, and high cost, and achieve the effects of easy control, convenient use, and reduced R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Weigh 1000 mesh 5kg metal pure magnesium powder, and weigh 1000 mesh 0.3kg metal pure zinc powder at the same time, put the above raw material powders into different metal powder storages for standby.

[0055] The dynamic flow rate control valve is controlled by the control system, so that the powder flow rates in the two metal powder reservoirs are different, and then the Mg\Zn metal mixed powder with Zn content varying from 0% to 6% is obtained.

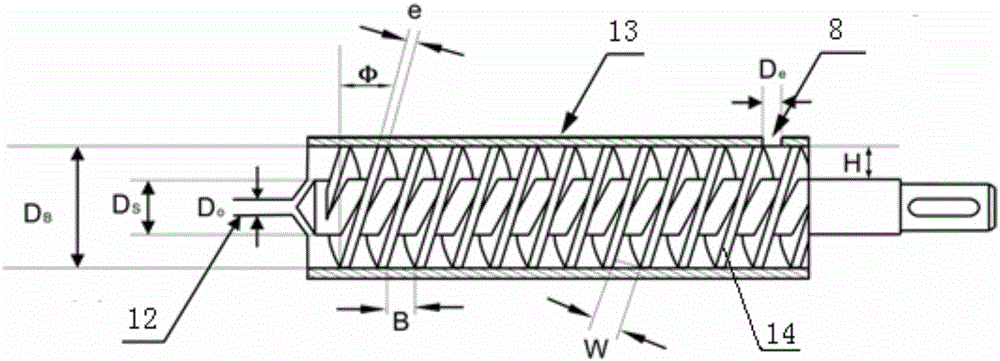

[0056] According to the flow rate of the metal powder inlet, adjust the screw speed:

[0057] r=(v e D. e 2 cosΦ) / {(D B 2 -D S 2 )·B}

[0058] In this example, the feeding speed is v e =1×10 5 mm / min; barrel inner diameter is D B =150mm, screw root diameter is D S =50mm; the diameter of the feed port is D e =20mm; the axial distance between the screw edges is B=50mm; the helix angle of the screw is Φ=37°, so the screw speed is calculated to be r=32 revolutions / min.

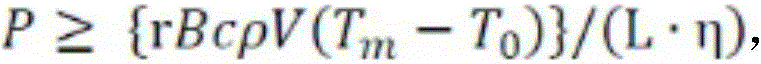

[0059] According to different raw materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com