Material mixture for producing casting moulds for machining metal

A modeling material and metal processing technology, applied in the direction of metal processing equipment, casting molds, manufacturing tools, etc., can solve problems such as impossible safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Influence of Synthetically Prepared Amorphous Silica on the Strength of Shaped Body Using Quartz Sand as Modeling Basic Material

[0078] 1. Preparation and testing of molding material mixture

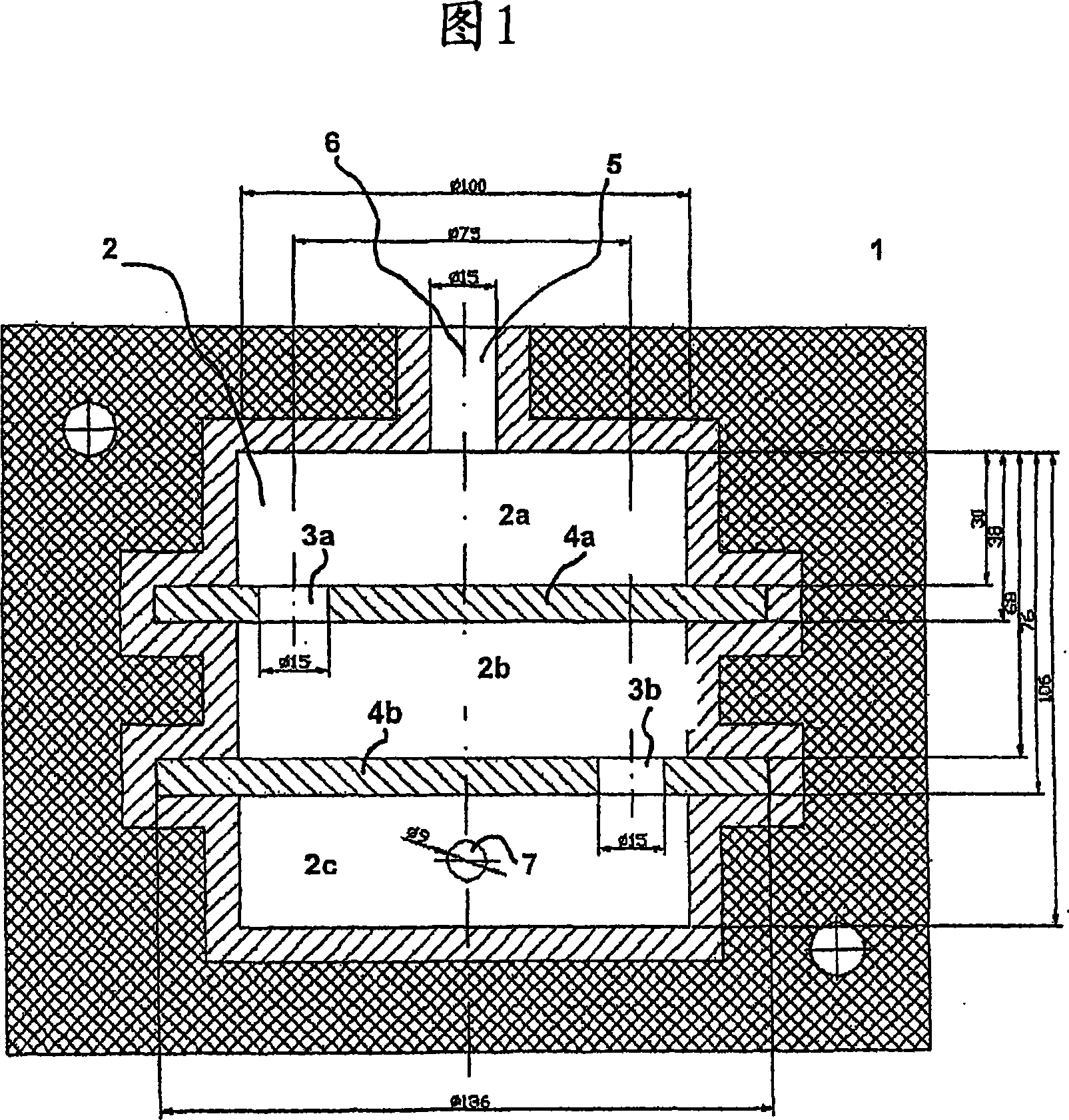

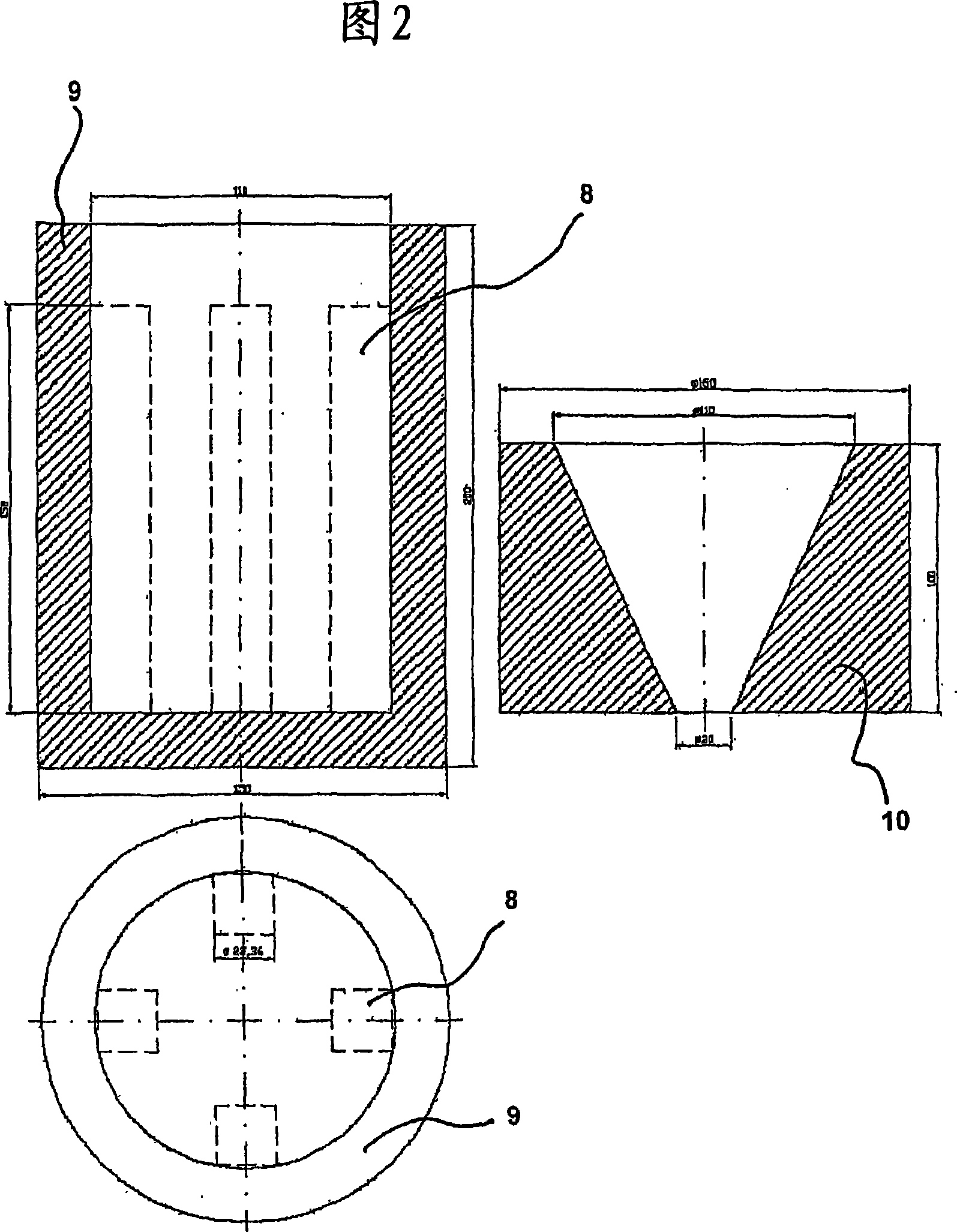

[0079] So-called Georg-Fischer test pins are produced for testing molding material mixtures.

[0080] A Georg-Fischer test pin is understood to be a cuboid test pin with dimensions 150 mm×22.36 mm×22.36 mm.

[0081] The composition of the molding material mixture is given in Table 1. To prepare the Georg-Fischer test pins proceed as follows:

[0082] - The components listed in Table 1 were mixed in a laboratory paddle mixer (Vogel & Schemmann AG, Hagen, DE). To do this, first precharge the quartz sand and add the water glass with stirring. Sodium water glass is used as water glass, which has a certain proportion of potassium. Therefore in the following table the SiO 2 : M 2 The modulus of O, where M is given is the sum of sodium and potassium. After the mixture was stirred...

Embodiment 2

[0114] Influence of the alkali water glass:amorphous silica ratio on the strength of shaped bodies with quartz sand as molding base material at a constant total binder quantity.

[0115] 1. Preparation and testing of molding material mixture

[0116] The preparation of the molding material mixture and its testing were carried out analogously to Example 1. The composition of the molding material mixture used to prepare the test pins is listed in Table 3. The values obtained in the flexural strength test are listed in Table 4.

[0117] table 3

[0118] Composition of the molding material mixture

[0119] Quartz sand

H32

water glass b)

amorphous

silica c)

2.1 a)

100GT

2.5GT

-

compare, not root

According to the present invention

2.2

100GT

2.3GT

0.2 GT

According to the present invention

2.3

100GT

1.9 GT

0.6 GT

Accordin...

Embodiment 3

[0129] Effect of silane on the strength of moldings

[0130] 1. Preparation and testing of molding material mixture

[0131] The preparation of the molding material mixtures and their testing was carried out analogously to Example 1. The composition of the molding material mixture used to prepare the test pins is listed in Table 5. The values obtained in the flexural strength test are listed in Table 6.

[0132] table 5

[0133] Composition of the molding material mixture

[0134] Quartz sand

H32

water glass c)

amorphous

silica d)

3.1 a)

100GT

2.5GT

---

---

compare, not root

According to the present invention

3.2 b)

100GT

2.5GT

0.2 GT

---

According to the present invention

3.3

100GT

2.5GT

0.2 GT

0.02

GT e)

According to the present invention

3.4

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com