On-line purification equipment for metal machining fluid and purification method thereof

A metal cutting fluid and purification equipment technology, applied in chemical instruments and methods, metallurgical wastewater treatment, oxidized water/sewage treatment, etc., can solve the problems of incomplete removal of microorganisms, poor oil separation effect, complex equipment, etc., to reduce waste The effect of liquid production, energy saving, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

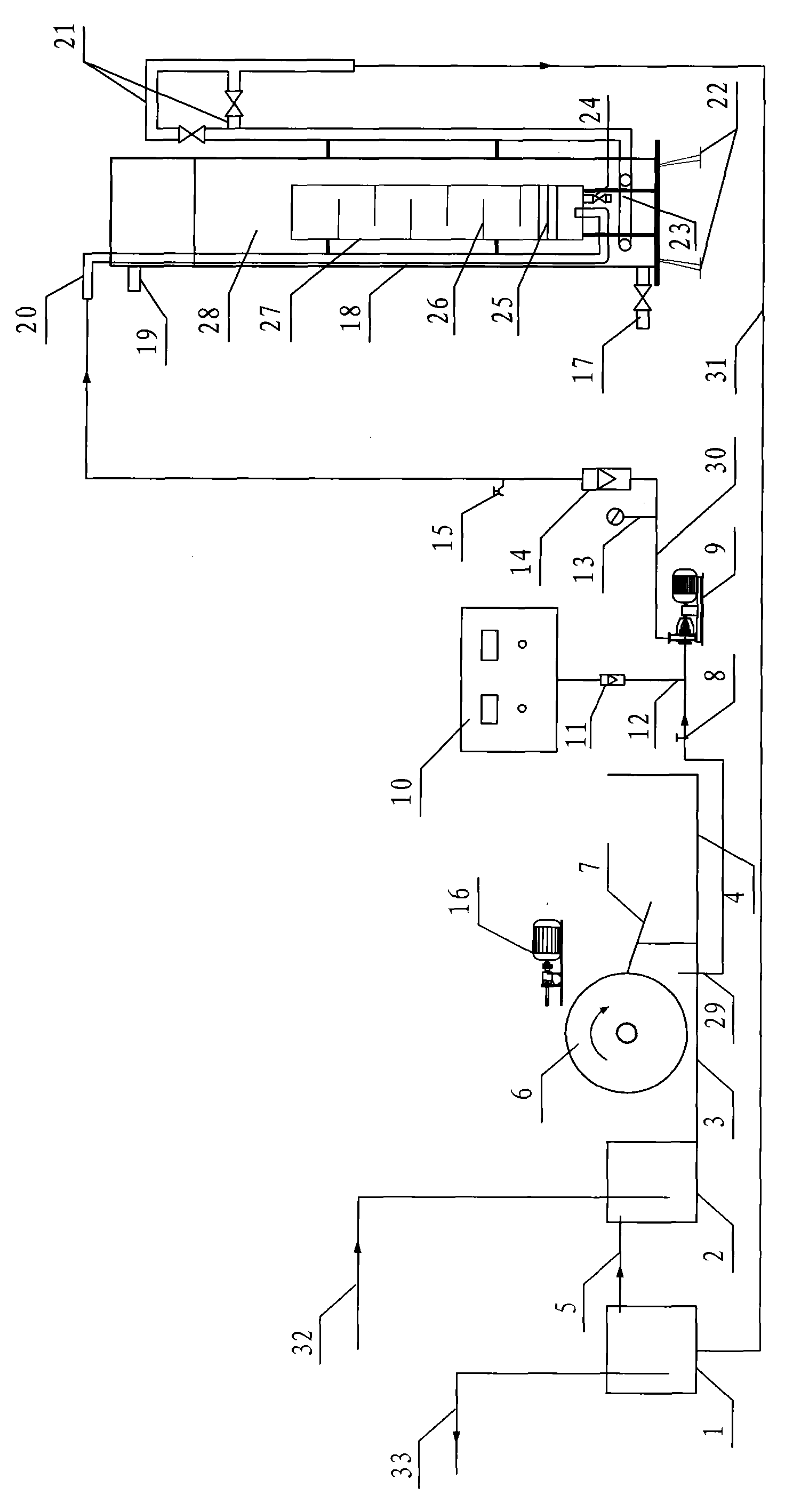

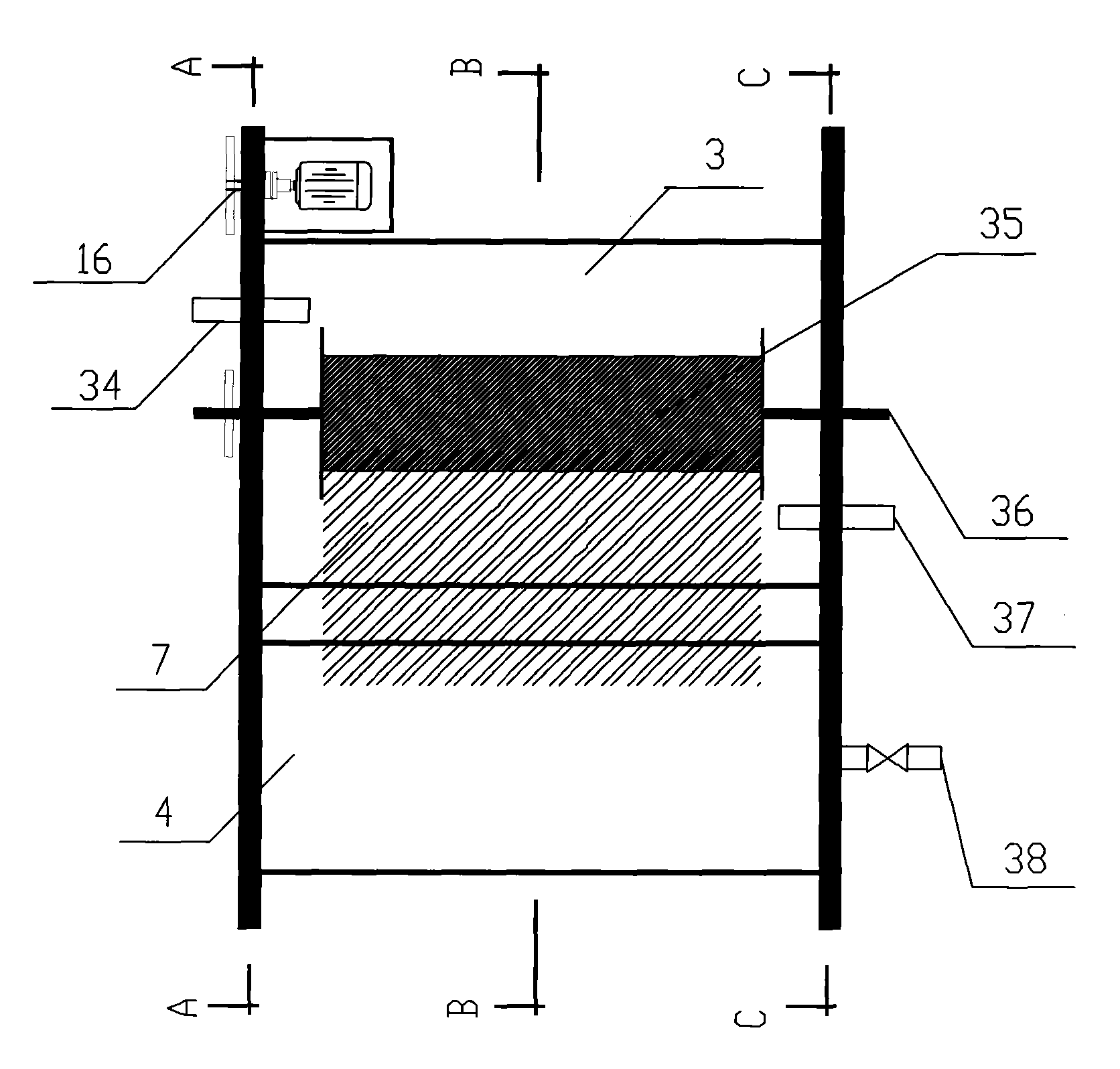

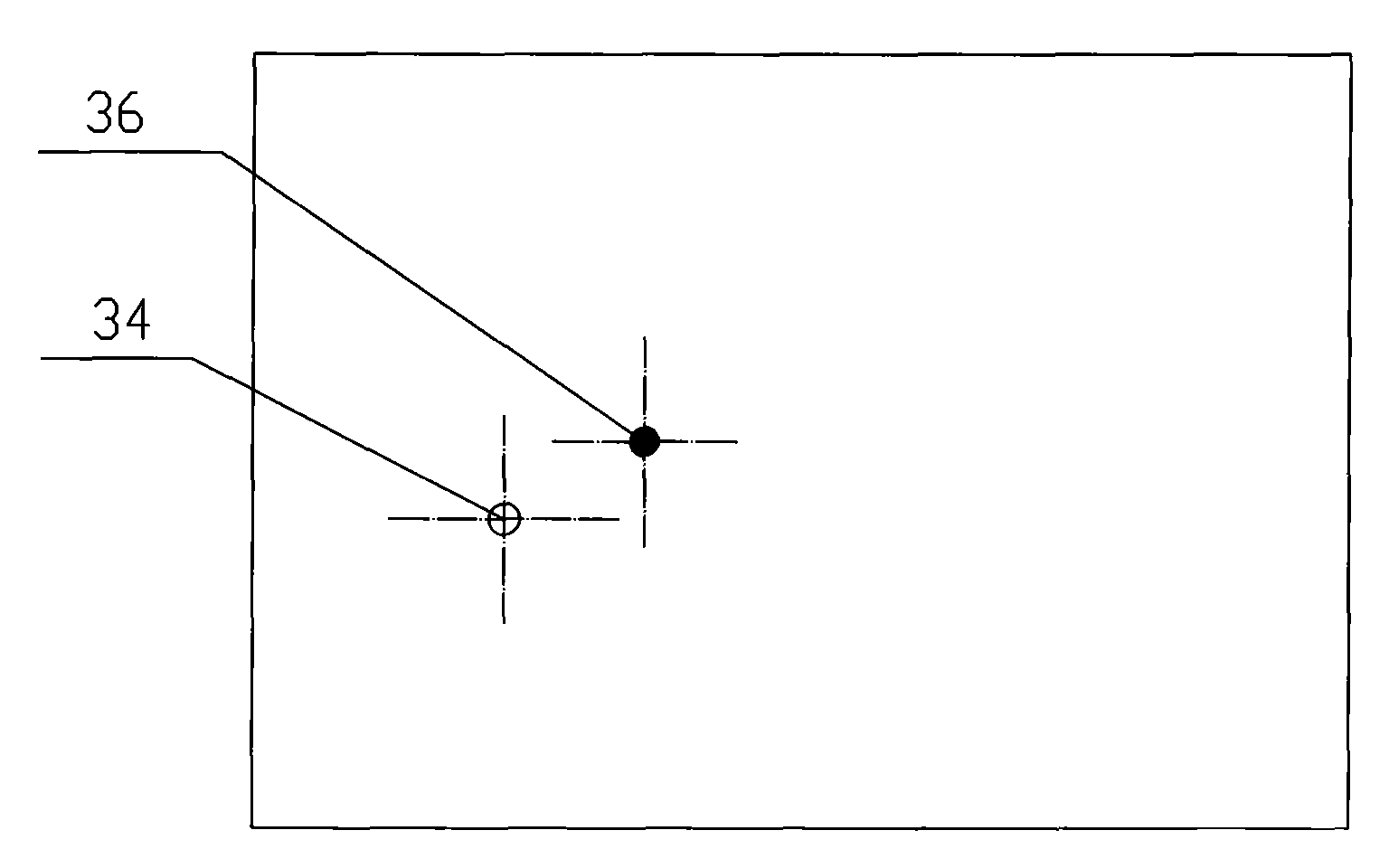

[0031] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-Figure 8As shown, a metal cutting fluid online purification equipment includes a purification liquid storage tank 1, a raw liquid storage tank 2, a magnetic separation tank 3, a magnetic slag storage tank 4, a drum-type multi-stage magnetic separation device 6, a gas-liquid mixing pump 9, an ozone Generator 10, ozone copolymerization air flotation sterilization separation device 18, Y-shaped outlet pipe 21; the purified liquid storage tank 1 is connected to the metal cutting equipment through the purified liquid online output pipe 33, and is connected to the stock solution storage tank through the return pipe 5 2. The stock solution storage tank 2 is connected to the metal cutting equipment through the stock solution input pipe 32, and there is a partition between the stock solution storage tank 2 and the magnetic separation tank 3, the magnetic separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com