Suspension cone bucket type semi-solid metal slurry preparation and conveyor device

A semi-solid metal and conveying device technology, applied in the field of suspension cone-type semi-solid metal slurry preparation and conveying device, can solve the problems of low production efficiency, low temperature control precision, long cycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

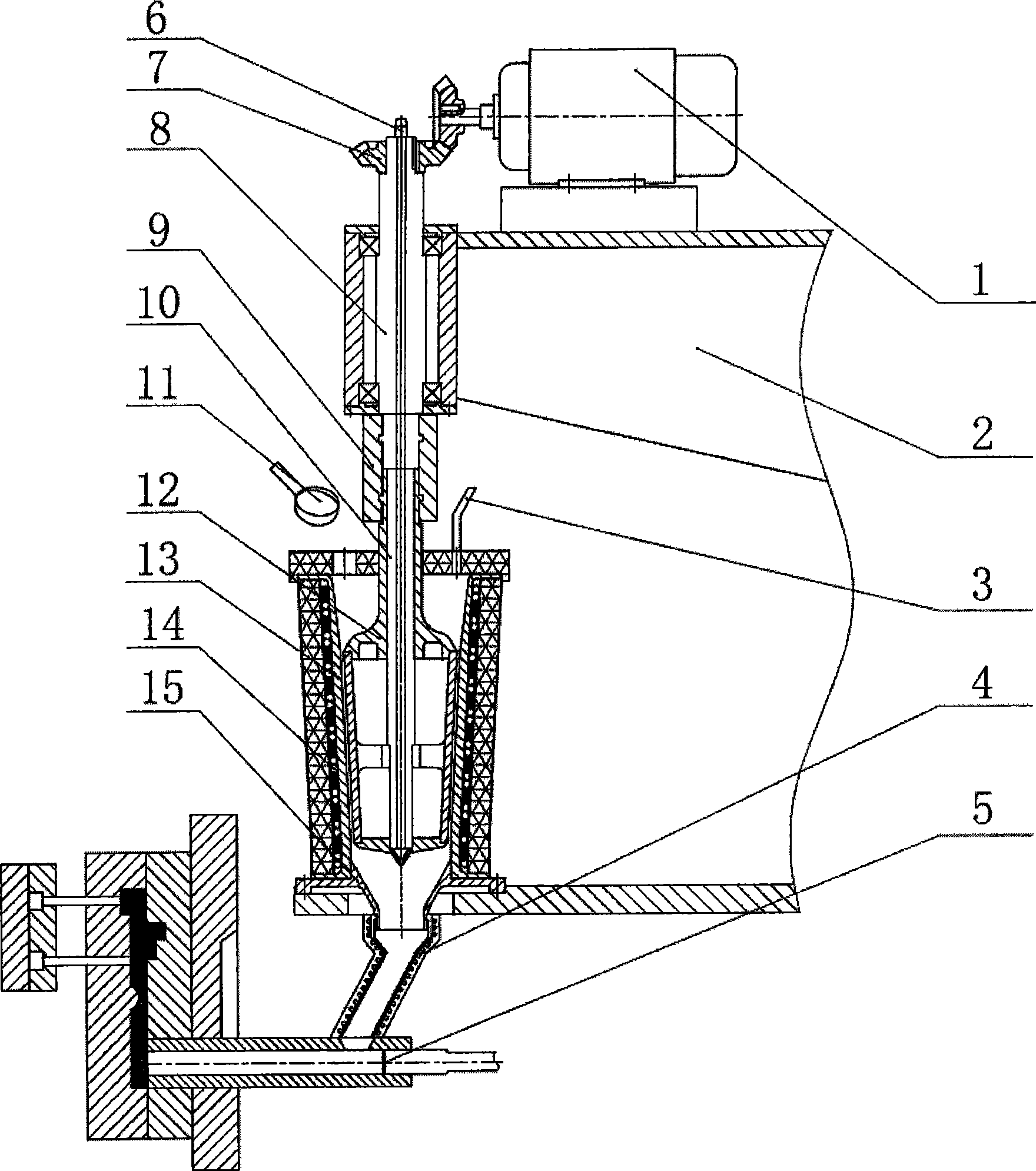

[0024] The structure and implementation effect of the present invention will be further described below according to the accompanying drawings and examples.

[0025] A suspended cone type semi-solid metal slurry preparation and delivery device, which consists of a speed-regulating motor 1, a lifting mechanism 2, a vent pipe 3, a connecting device 4, a die-casting machine injection chamber 5, a vent 6, a transmission bevel gear 7, Mandrel 8, coupling 9, air pipe 10, pouring spoon 11, inner cone barrel 12, outer cone barrel 13, heating and cooling element 14, flange plate 15 and so on. The speed regulating motor 1 can carry out stepless speed regulation, the speed range: 0~900rad / min; the speed of the inner cone barrel 12 is realized by driving the transmission bevel gear 7 through the speed regulating motor 1; the speed between the inner cone barrel 12 and the outer cone barrel 13 The gap can be realized by adjusting the lifting mechanism 2, the adjustment range: 3mm ~ 6mm; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com