Tank-carrying hydraulic automatic discharging vehicle

A loading and unloading truck and hydraulic technology, which is applied in the direction of tilting and carrying vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

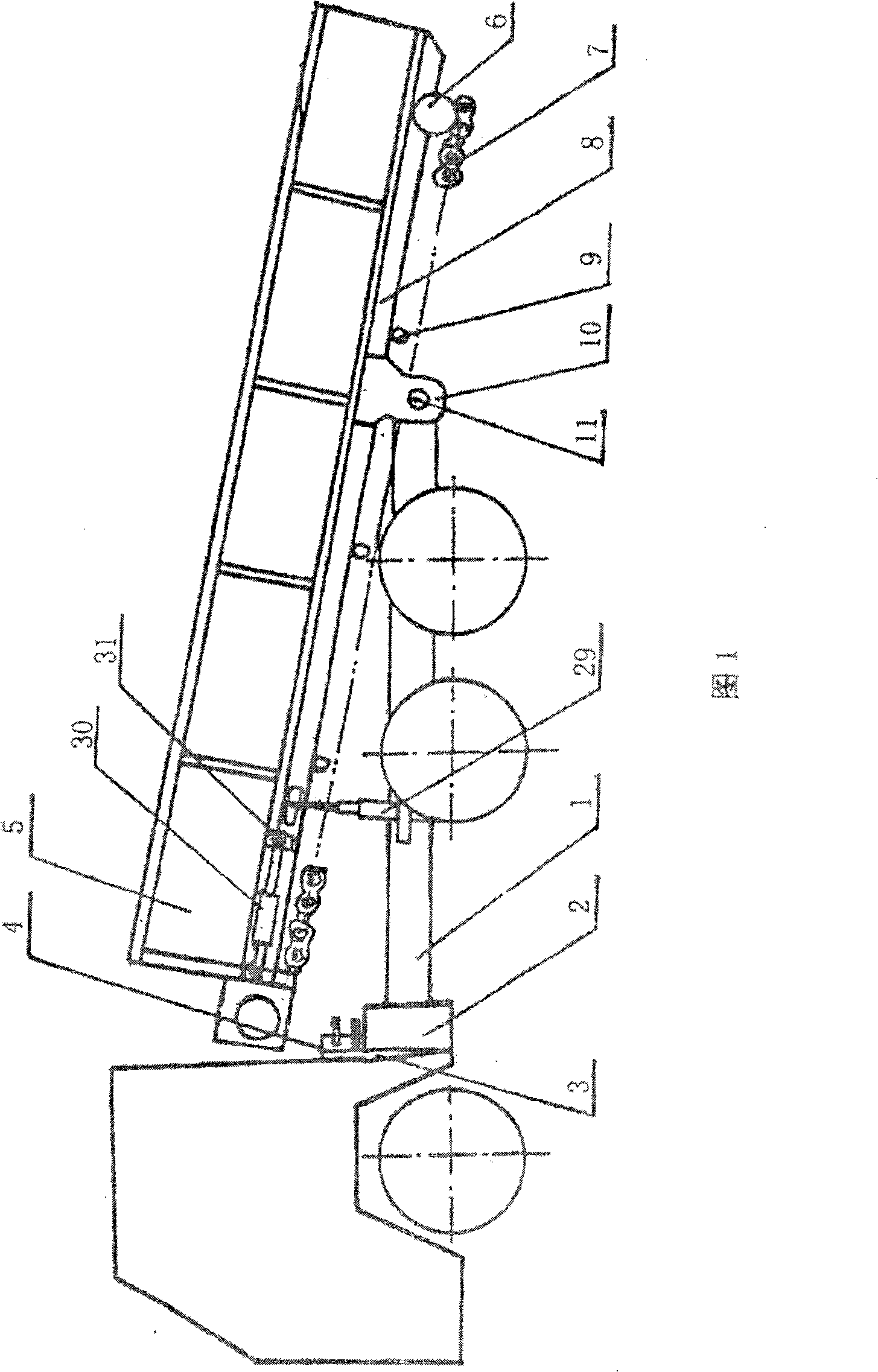

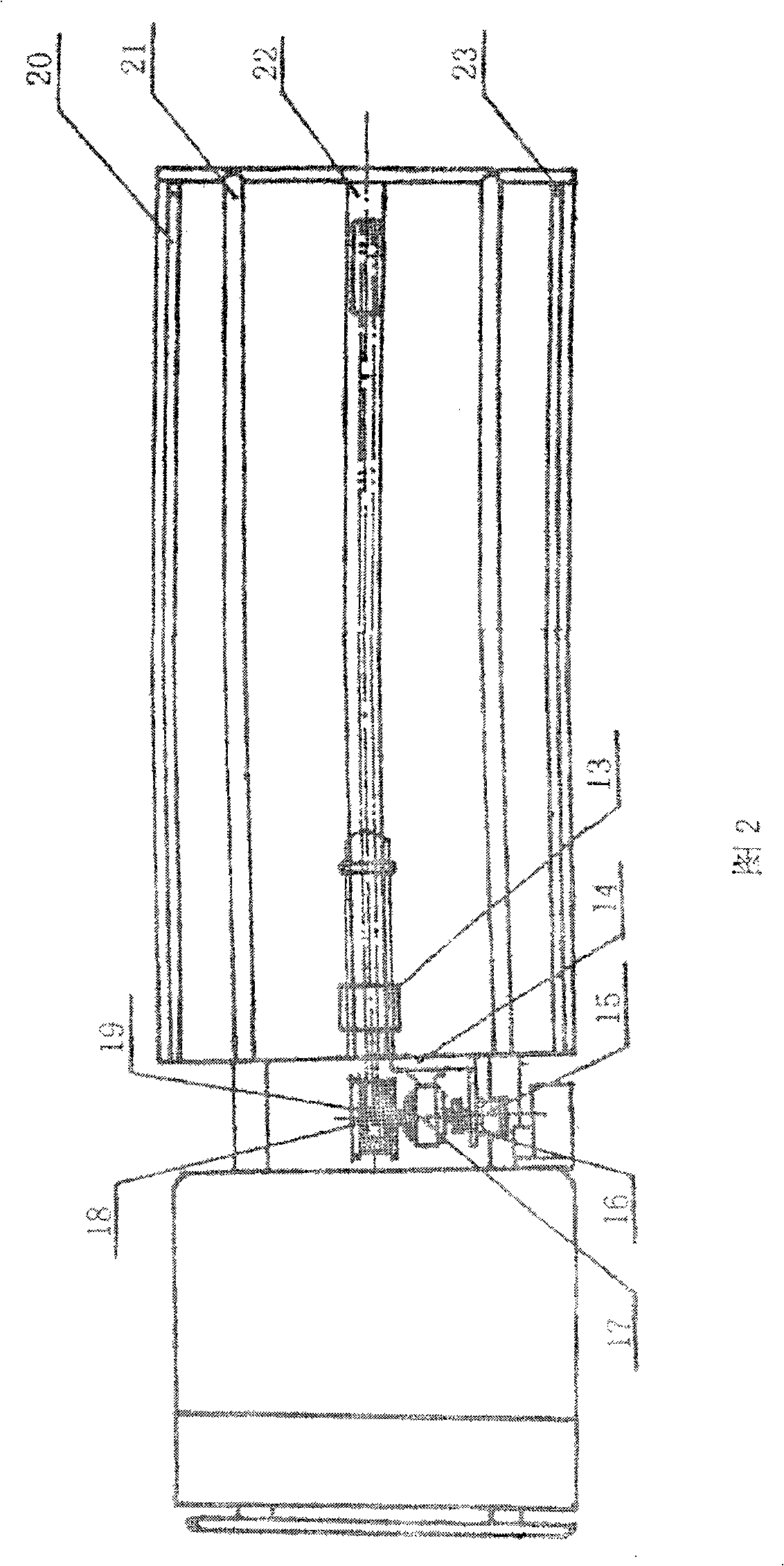

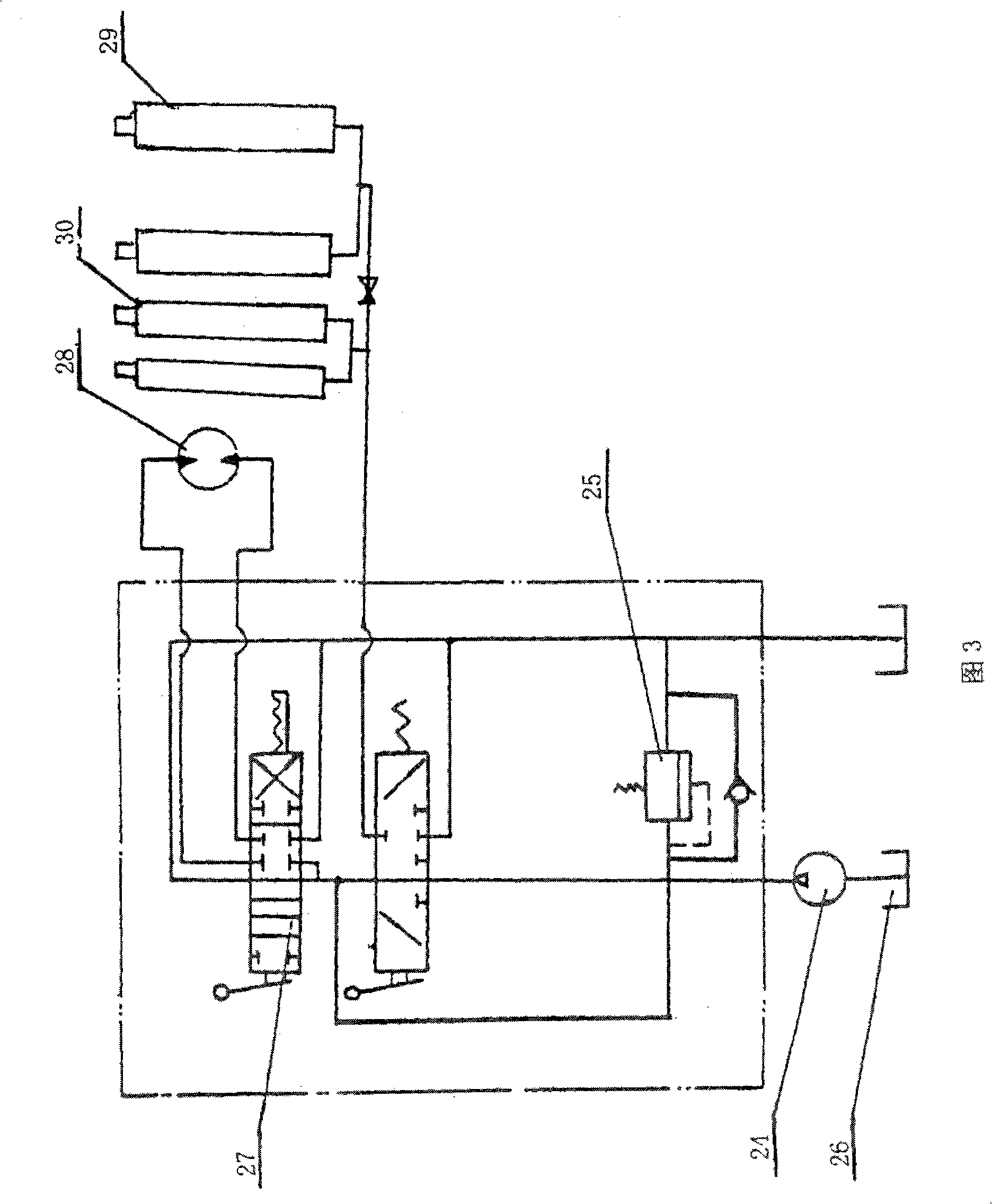

[0009] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0010] The automatic back tank loading and unloading truck is composed of a carriage guiding system, a chain transmission system and a hydraulic transmission system connected thereto. When the tank car is working, the hydraulic oil pump 24 distributes the power fluid to the carriage hydraulic cylinders 29 and 30 through the hydraulic reversing valves 4 and 27, the hydraulic pistons stretch out, the movable carriage moves forward and the rear end rises and the tail contacts the ground. The power fluid to the valves 4 and 27 enters the hydraulic oil motors 15 and 28 in different directions to realize forward and reverse rotation. Move forward with the wire rope hanger 13, and the tank body hung with the wire rope hanger 13 runs to the front end of the movable carriage at the same time, un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com