Dicing and shredding machine

A shredding machine and dicing technology, which is applied in metal processing and other fields, can solve the problems of high labor cost, low production capacity, unsuitable for factory industrial production, etc., and achieve the effect of simple structure and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

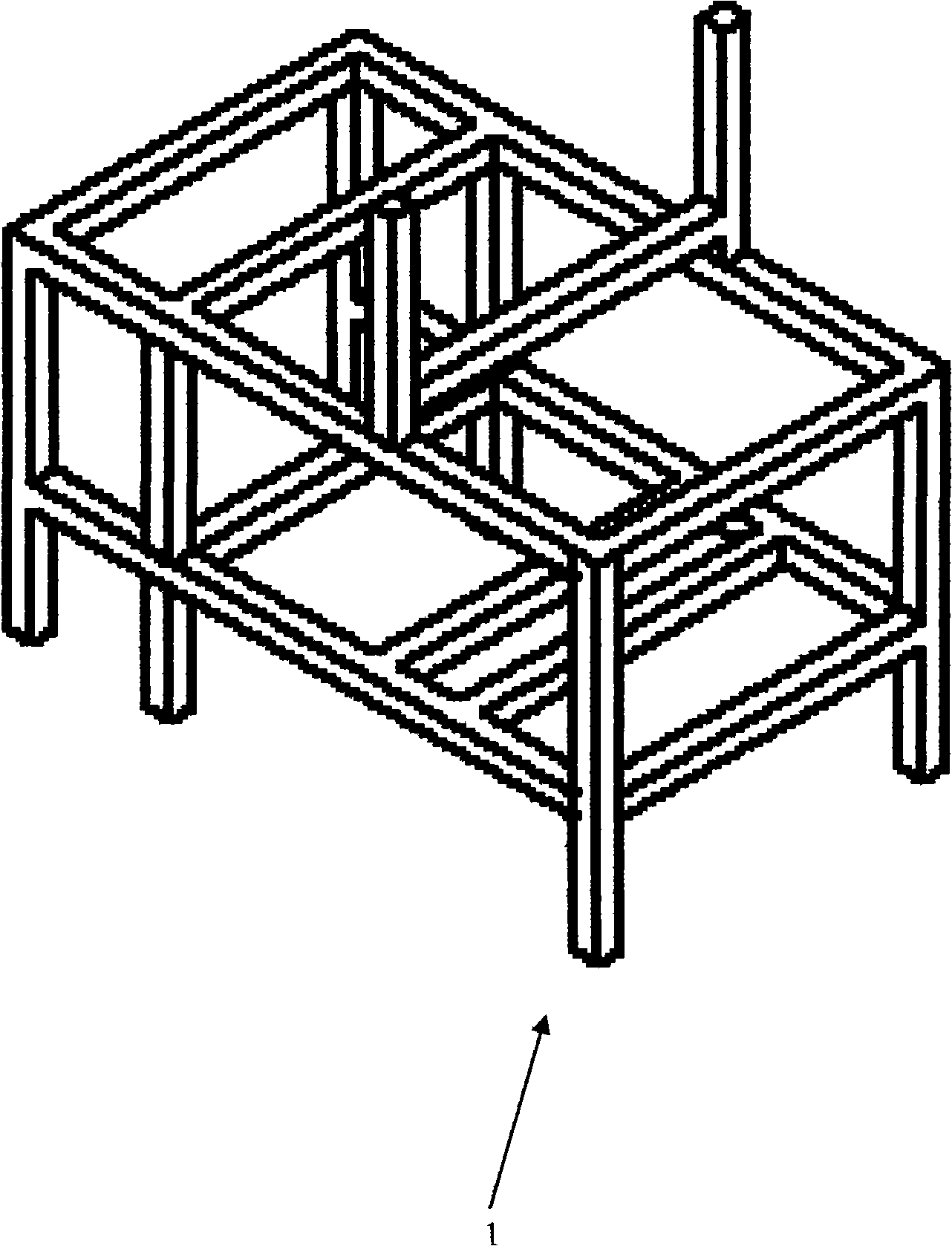

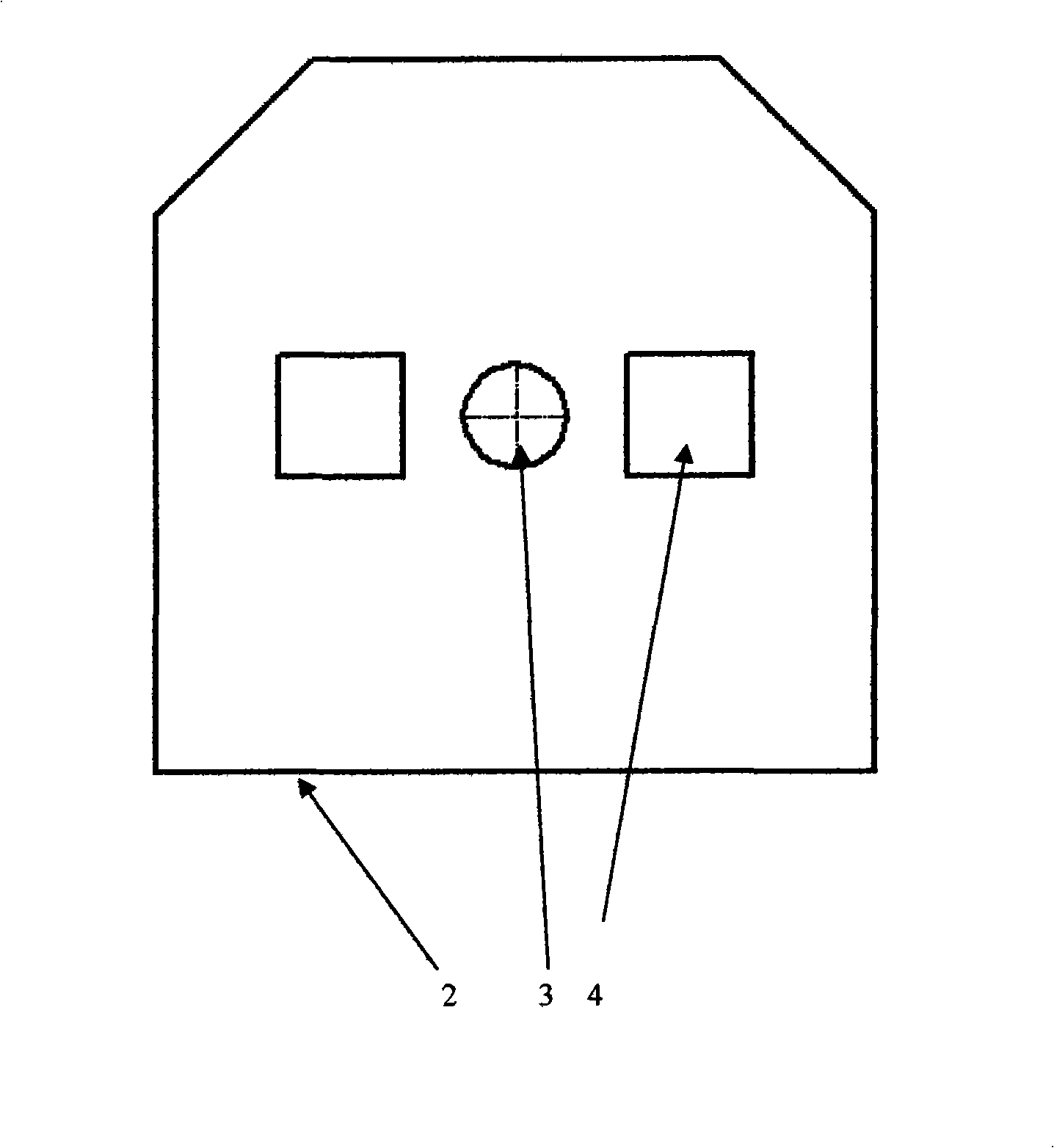

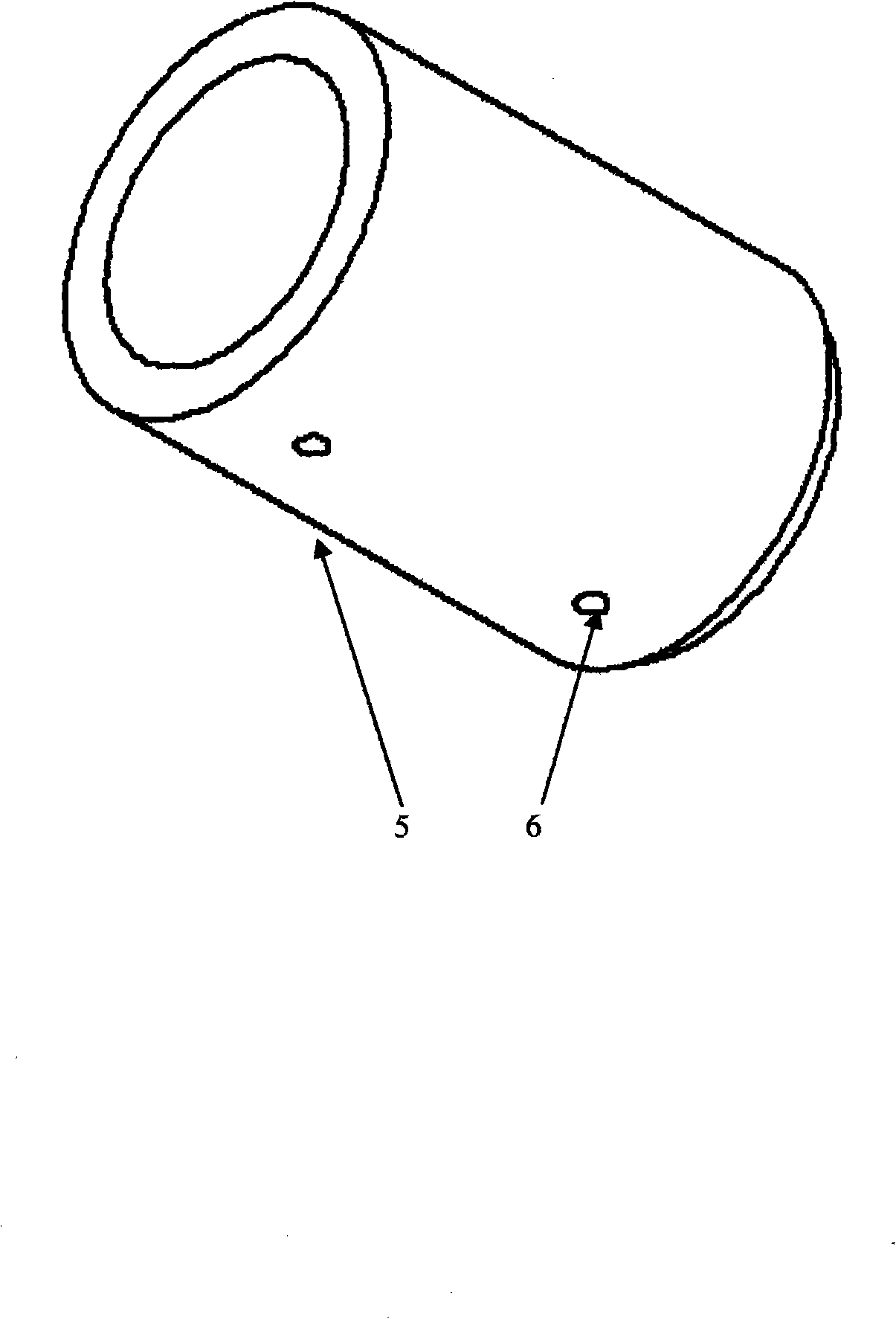

[0041]In Figure 32, it is the overall structure diagram of the dicing and shredding machine. The panel assembly is welded on the frame, and the cutterhead assembly is installed on the front end of the cutterhead shaft and fastened with nuts. The two pistons in the crank-link mechanism are respectively Put it into the two piston cylinders, the crank shaft bearing in the crank connecting rod mechanism is installed on the crank shaft bearing fixing frame behind the piston sleeve, the shredder is placed in the shredder support hole, and the crankshaft reducer drive system The reducer is installed on the frame, the crank shaft gear is installed in the middle of the crank shaft, the reducer in the drive system of the blade disc reducer is installed on the frame, and the gear at the other end is installed at the rear end of the cutter head shaft, and the feed The bucket is installed above the piston sleeve, the square hole in the feed hopper is aligned with the feed inlet on the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com