Manufacturing method of composite additional material

A technology of additive manufacturing and model components, which is applied in the field of composite additive manufacturing multi-functional multi-material model components, can solve the problems of single material and single function of model components, and achieve increased strength and reliability, improved reliability, The effect of increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

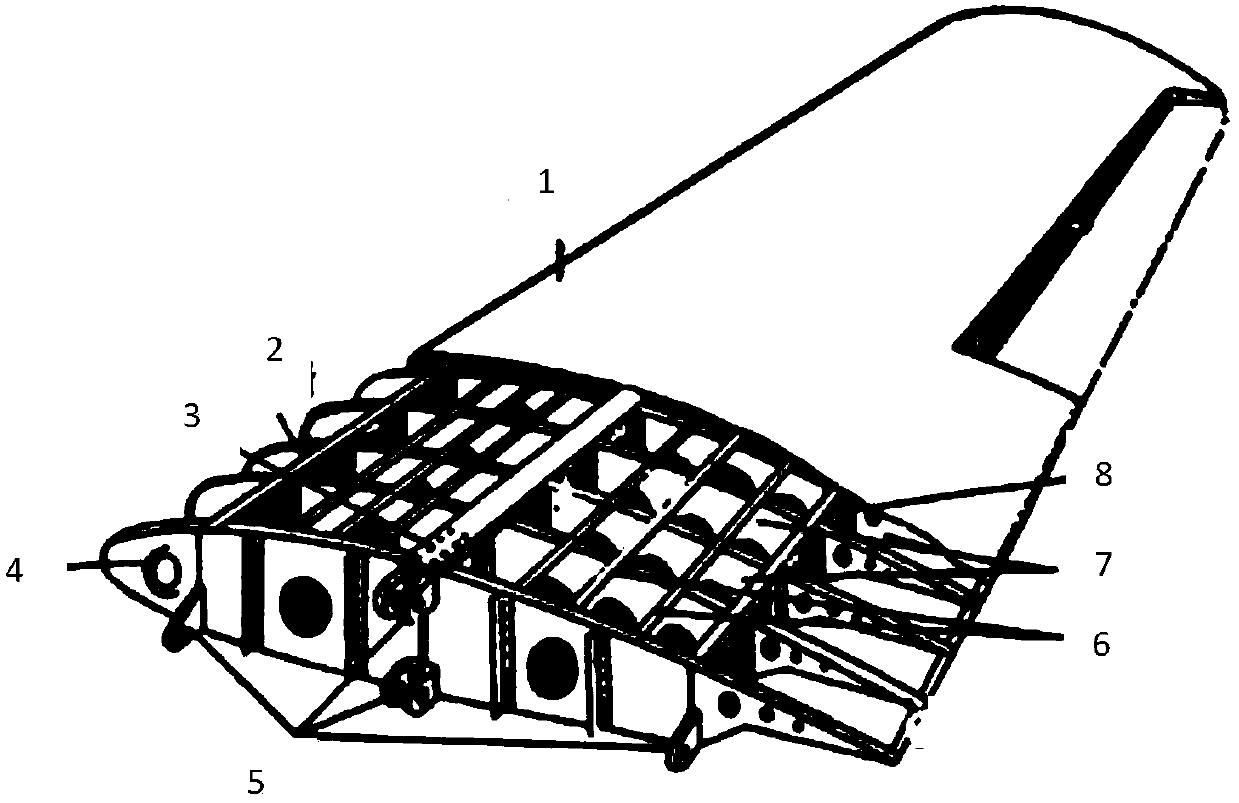

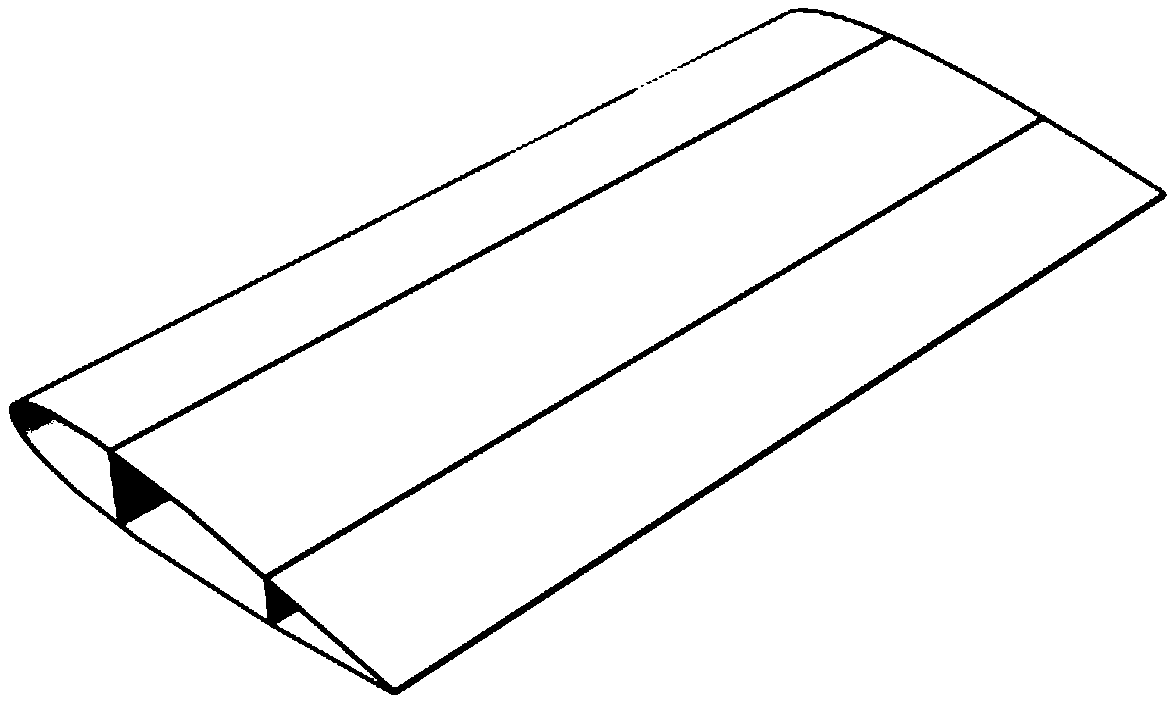

[0026] Taking the composite manufacturing of fixed-wing aircraft wings as an example, first use CAD to design the structure diagram of fixed-wing aircraft wings, as shown in figure 1 shown. In the wing structure, the positions of the skin 1, the front wall 2, the spar 3, the rib 4, the joint 5, the stringer 6, the rib 7 and the rear wall 8 on the wing are designed. Such as figure 2 A schematic diagram of the "programmable mold" for designing a fixed-wing aircraft wing is shown.

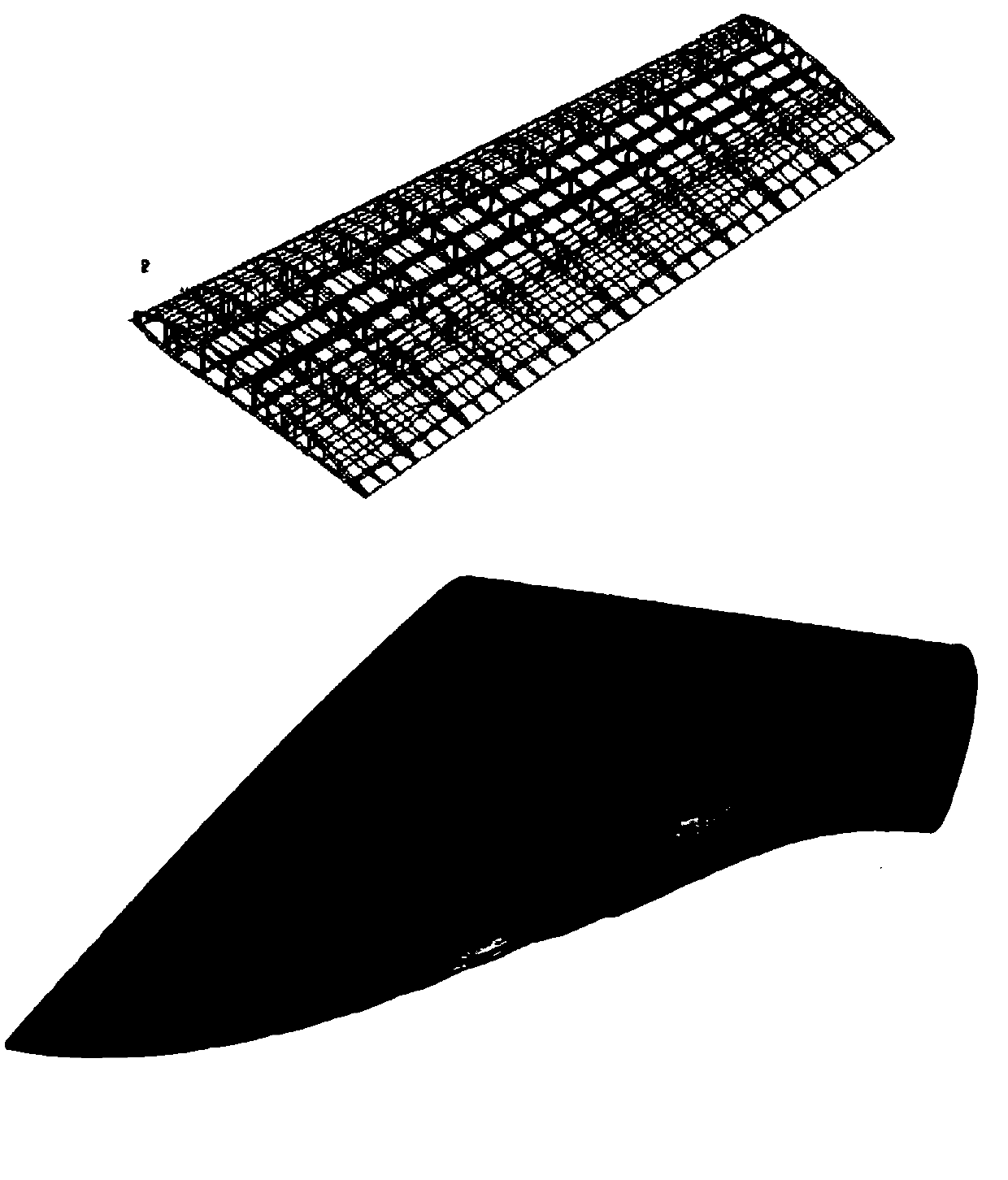

[0027] Then use the finite element analysis of the wing of the fixed-wing aircraft, such as image 3 shown. First, the wing is modeled to form a grid structure diagram of the aircraft structure, and then the cloud image of the finite element analysis of the aircraft wing during the simulated flight.

[0028] Through finite element analysis, it is clear that the front wall 2, spar 3, stiffener 4, joint 5, stringer 6, wing rib 7 and rear wall 8 are all stress-bearing supporting structures of the wi...

Embodiment 2

[0035]Taking the manufacture of smart prostheses as an example, smart prostheses are equipped with sensing devices such as multidimensional force sensors, Hall effect sensors, potentiometers, plantar pressure switches, and data acquisition chips. Among them, the multi-dimensional force sensor can detect and measure the ground reversal and moment of the three lines of defense. Real-time measurement of rigid body force / torque signals. The Hall sensor is easy to install, and the detection signal only has high and low level exchanges, which is easy to detect and use, and the walking speed can be calculated by the time when the detection level changes. The potentiometer acquires the joint angle at any time. The plantar pressure switch can detect the plantar pressure by itself and distinguish between support phase and swing phase.

[0036] In addition, an artificial rubber skin is installed on the outer cover of the prosthesis, and temperature, touch and humidity sensors are insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com