Numerical control irregular edge sealing and trimming system

A special-shaped sealing and trimming technology, which is used in wood processing appliances, household components, etc., to achieve the effect of wide application and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

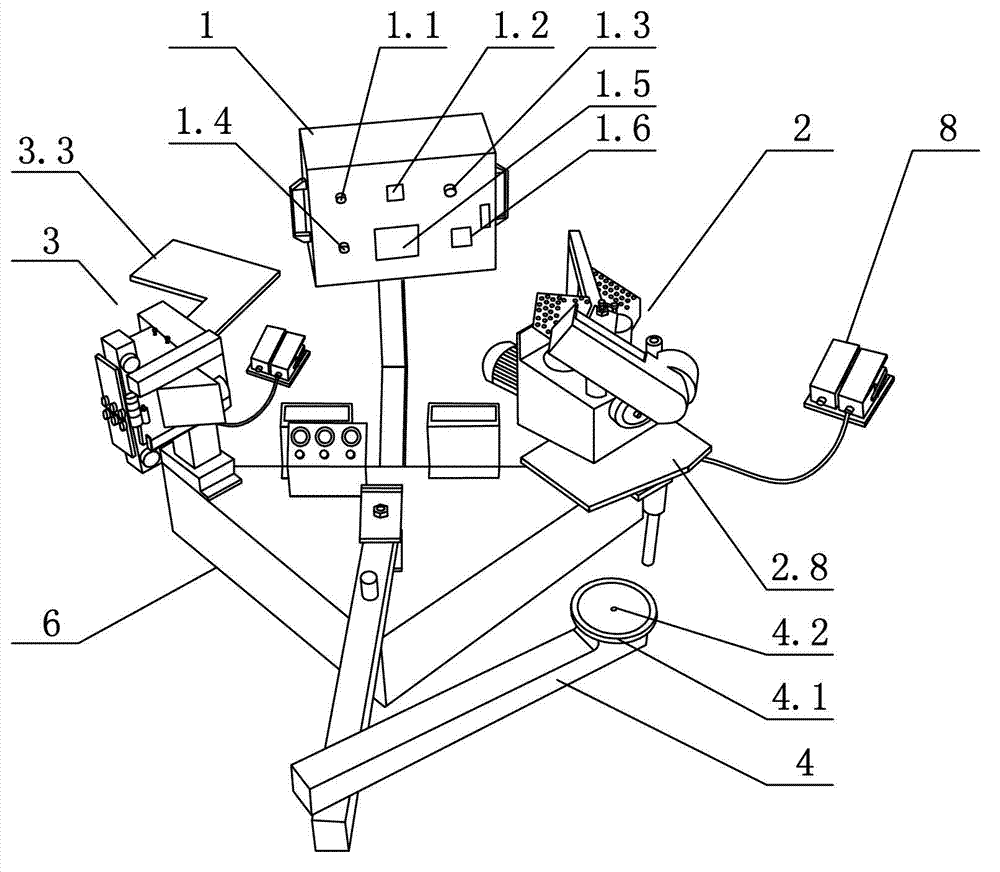

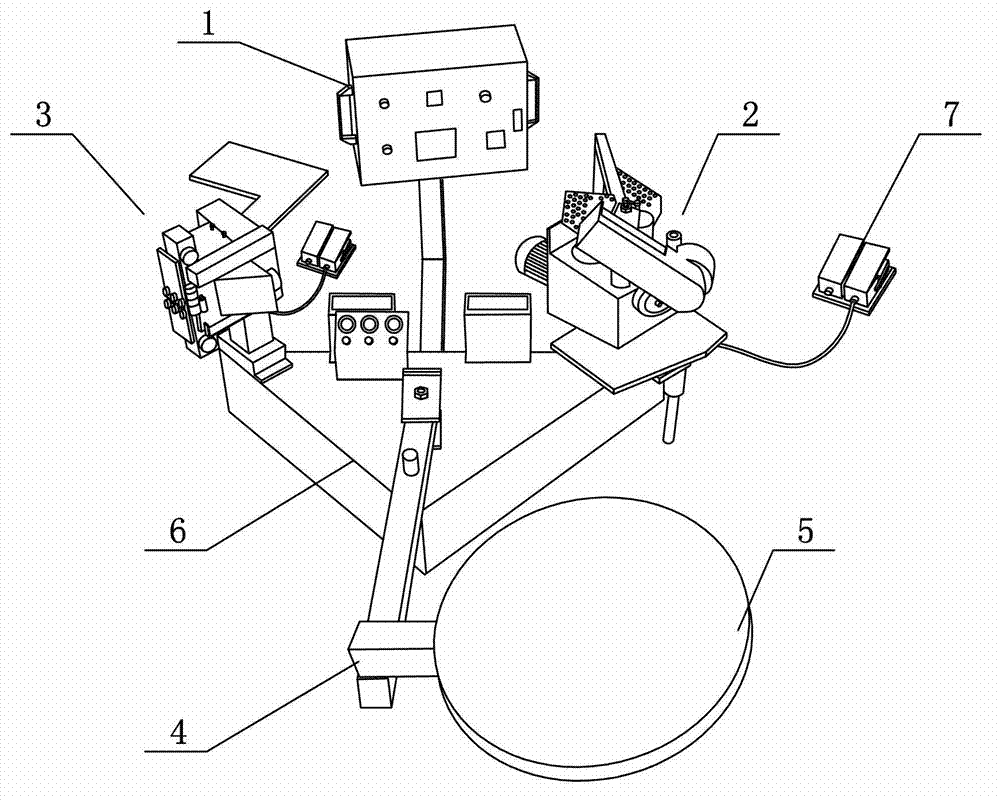

[0032] see figure 1 — Figure 10 , a CNC special-shaped edge banding and trimming system, comprising a triangular frame 6, a numerical control device 1 is arranged above the frame, and a CNC profiled edge banding assembly 2 and a profiled edge trimming assembly are respectively arranged on both sides of the frame 3. The numerical control device 1 includes an indicator light 1.1, a temperature controller 1.2, an emergency stop switch 1.3, a power switch 1.4, a liquid crystal touch panel 1.5 and a frequency regulator 1.6.

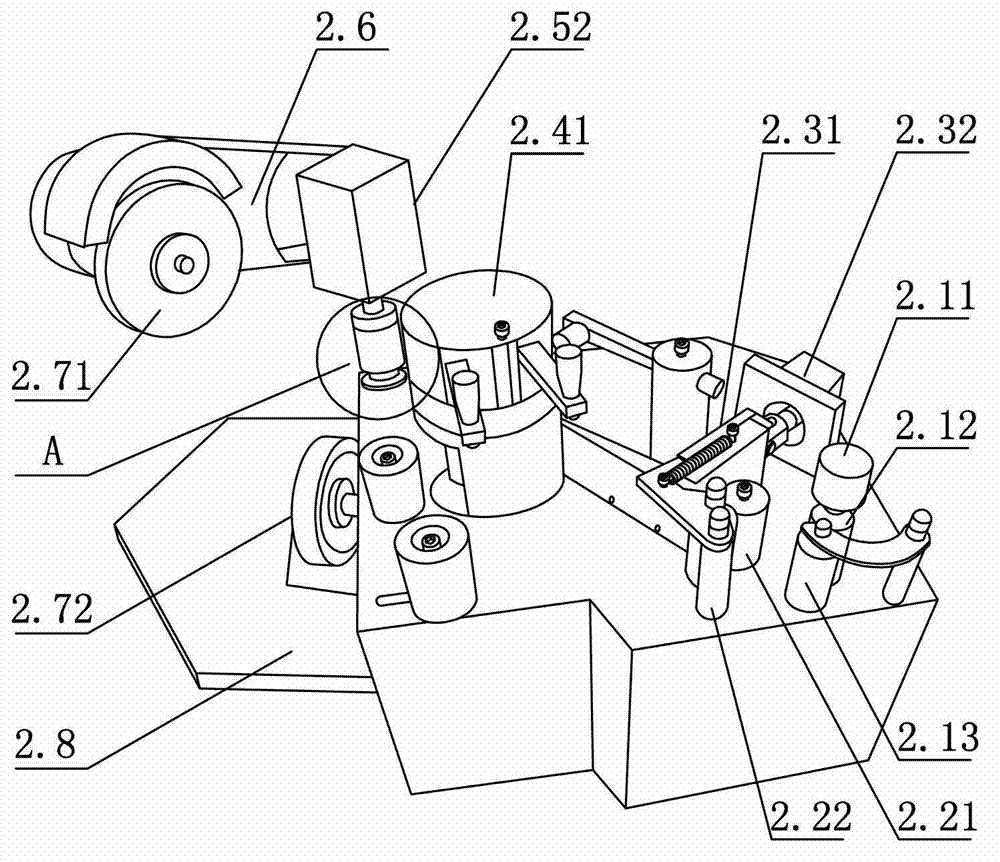

[0033] The CNC profiling edge banding assembly 2 includes an encoder wheel set, an edge feeding wheel set, a belt cutter 2.31, a gluing device, a blank holder shaft 2.5, a rocker arm 2.6, a profiling wheel set, a protective plate and a motor. The encoder wheel set includes two left and right runners, and the edge band 7 passes between the left runner 2.13 and the right runner 2.12, and the encoder 2.11 is arranged on the top of the right runner 2.12 and calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com