Vegetable cutter

A cutting machine and vegetable cutting technology, which is applied in metal processing and other directions, can solve the problems of single slicing form and inability to cut leafy vegetables into shreds and tuber materials, and achieve the effect of enhancing cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

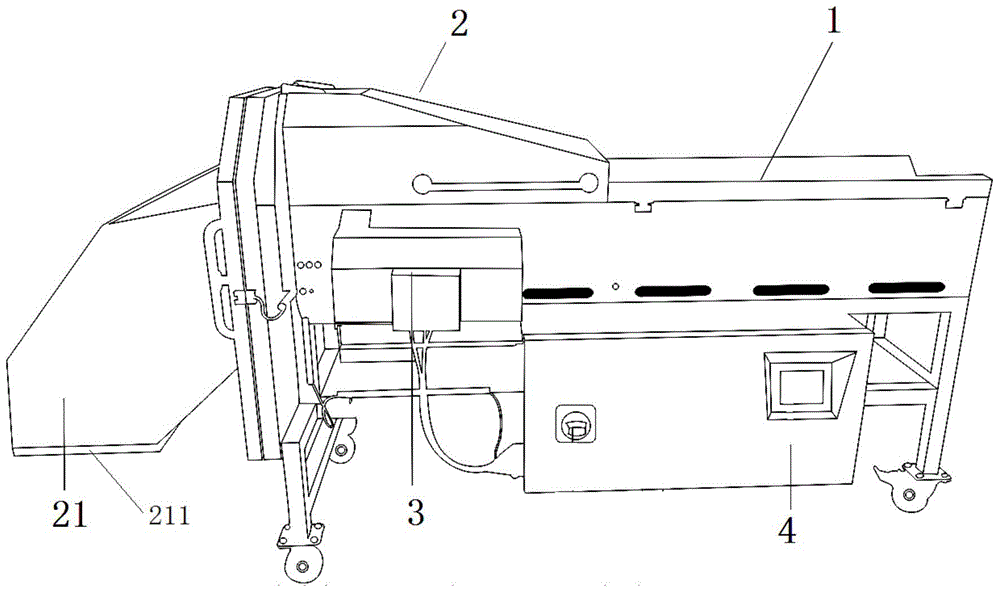

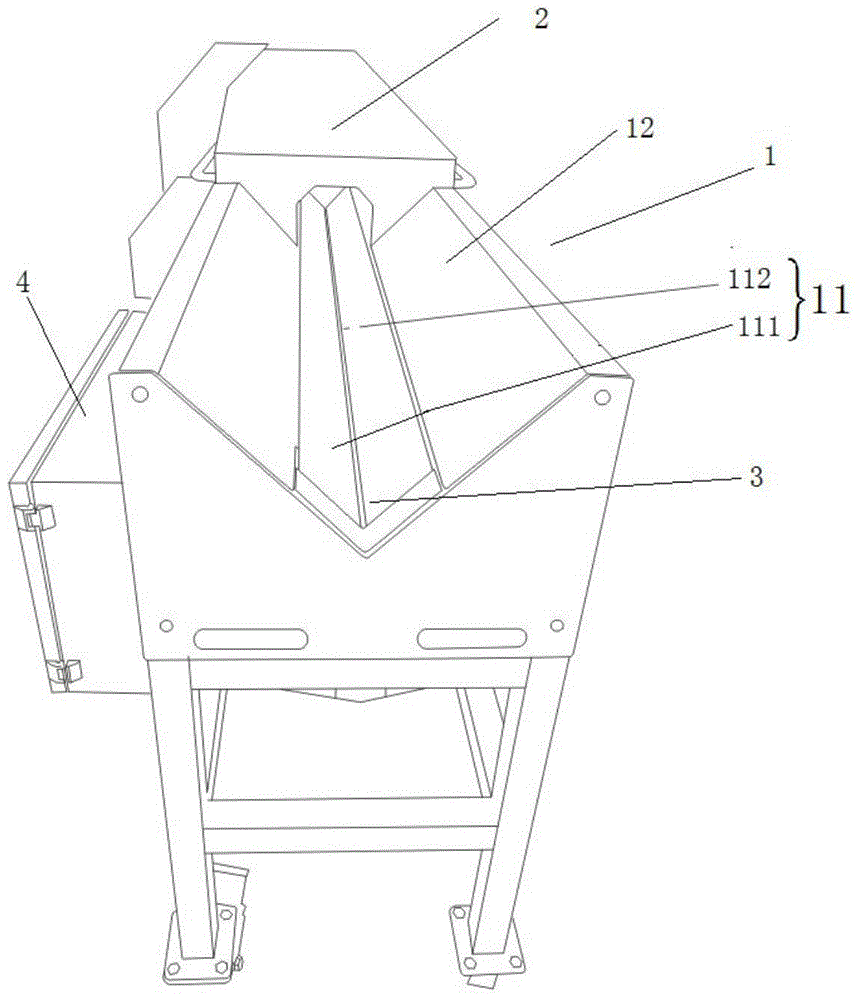

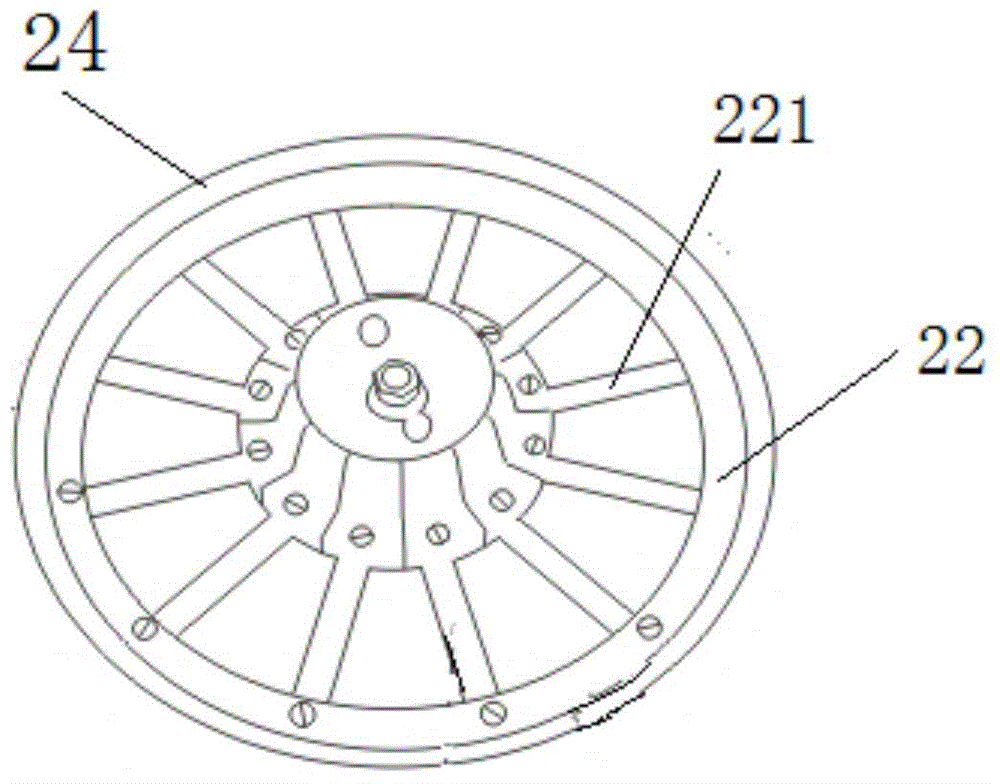

[0022] combine Figure 1 to Figure 4 As shown in the structure, the present invention provides a vegetable cutting machine, which includes a conveying device 1 and a cutting device 2, and the cutting device 2 includes a collection box 21, a circular cutter head 22, a first drive motor 23, and the collection box 21 is provided with a discharge port 211, and the circular cutter head 22 is vertically arranged in the collecting box 21, and is positioned at the conveying end of the conveying device 1, and the conveying direction of the conveying device 1 is vertically arranged with the circular cutter head 22, and the circular cutter The middle part of the disc 22 is fixedly connected with the drive end of the first drive motor 23, as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com