Forming hydraulic machine for hot-press seal head

A hydraulic press and head technology, applied in the field of hydraulic press equipment, can solve the problems of reducing the strength of the column 3 and the tensile slider 4, the height direction of the column 3 becoming longer, and the opening of the stretching slider 4 being large, etc. The effect of weight and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

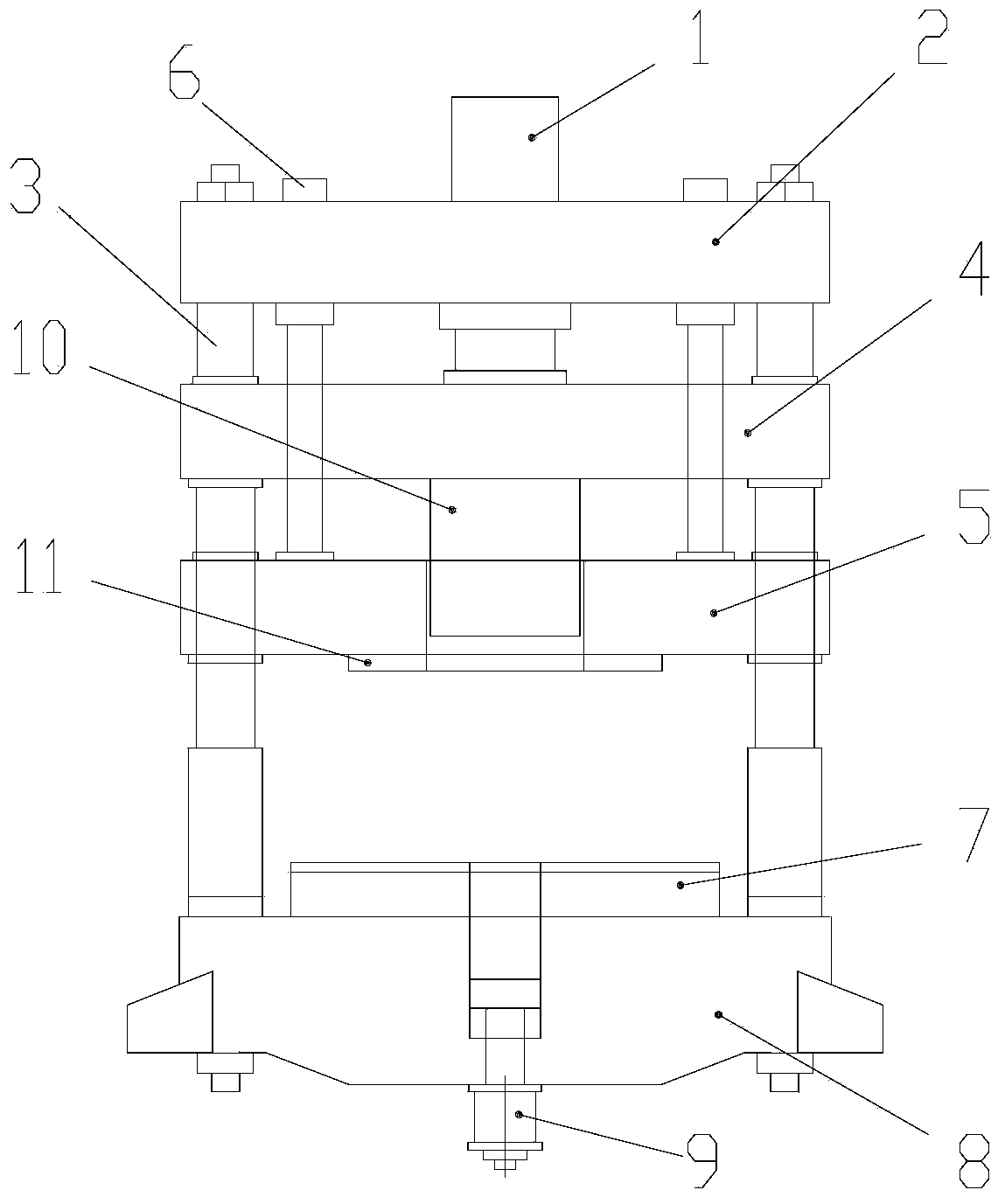

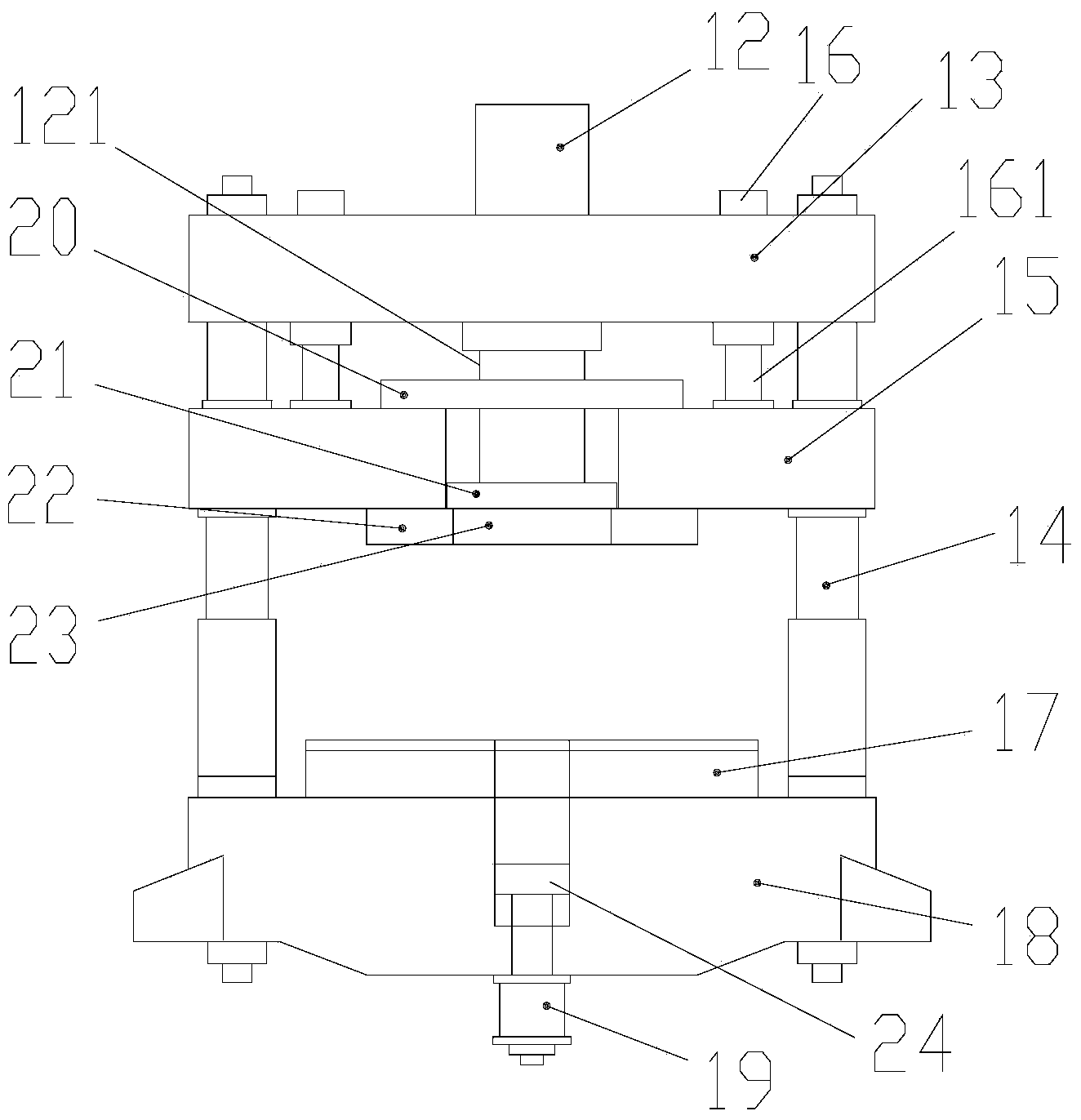

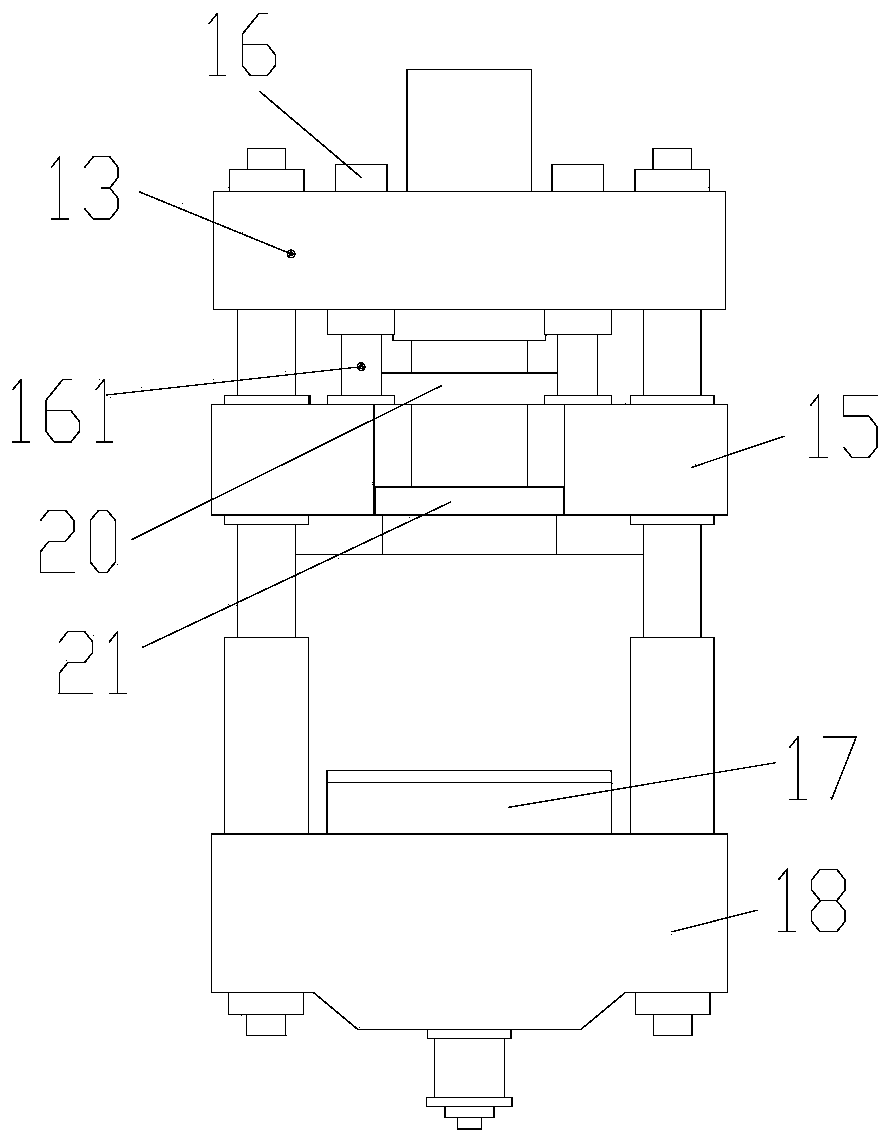

[0019] see figure 2 , image 3 , a kind of hot-pressed head forming hydraulic machine provided by the present invention comprises a frame, four columns 14 arranged on the frame, an upper beam 13 and a lower beam 18 fixedly arranged on the column 14, and the lower beam 18 is provided with Mobile workbench 17 is used to install lower mold on the mobile workbench 17. The lower end of the lower beam 18 is provided with an ejection cylinder 19, and the ejection cylinder 19 extends upwards with a push rod 24. Between the upper crossbeam 3 and the lower crossbeam 18, there is a blanking slider 15 that can move up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com