Combined fixture integrated platform

A combined fixture and integrated platform technology, applied in the direction of clamping, manufacturing tools, large fixed members, etc., can solve the problems of reduction, scrapping, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

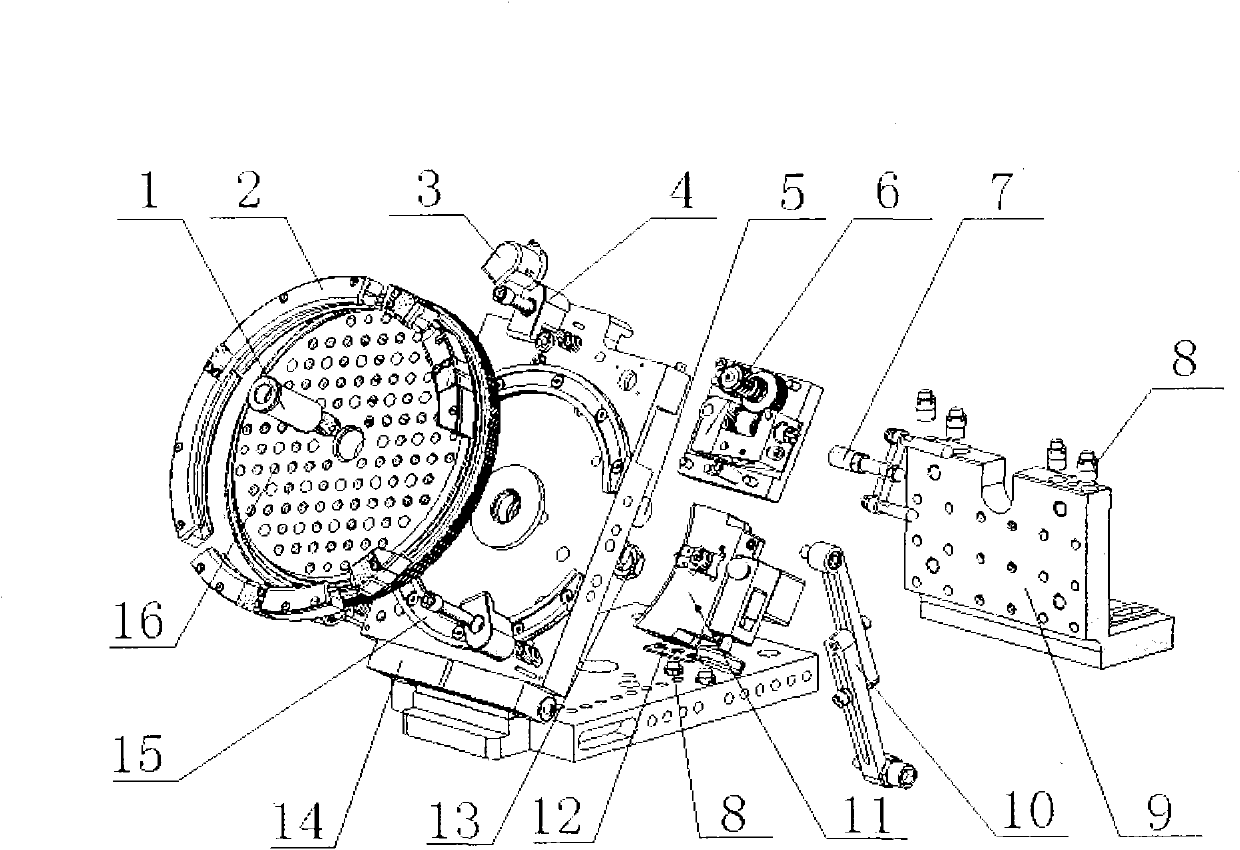

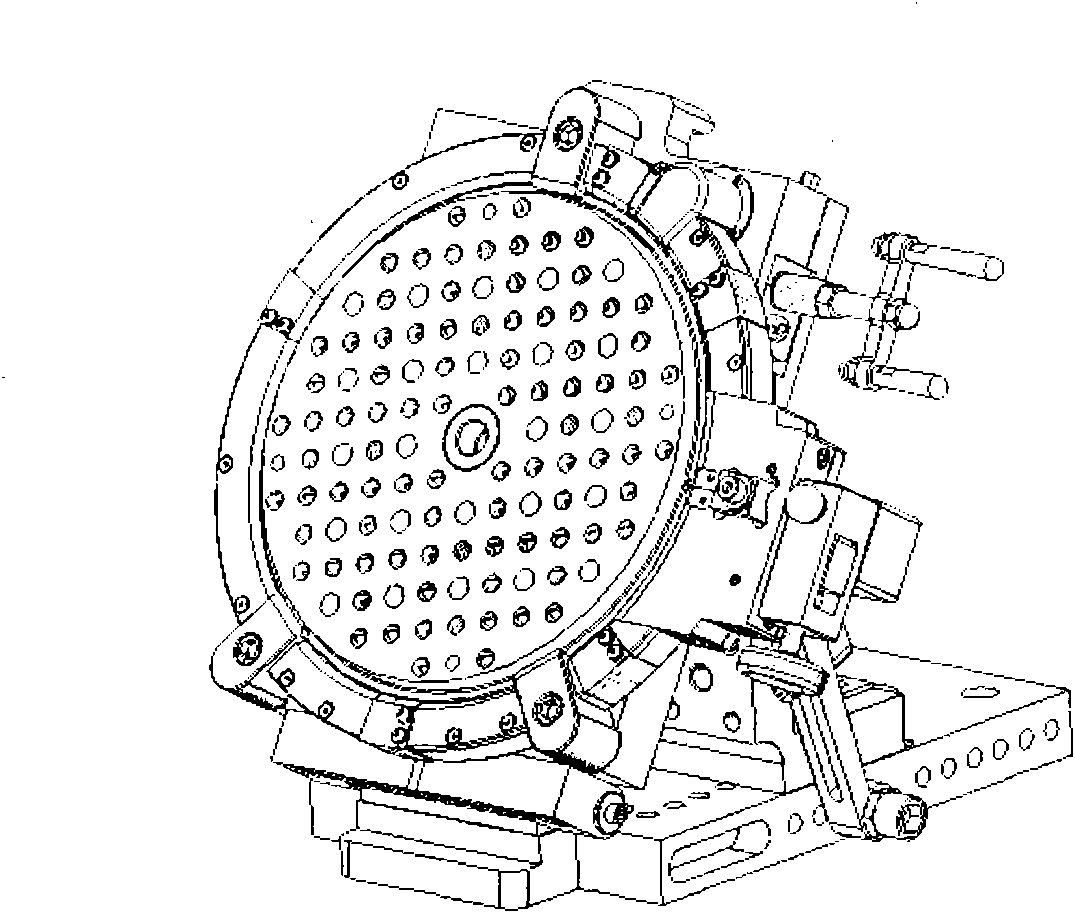

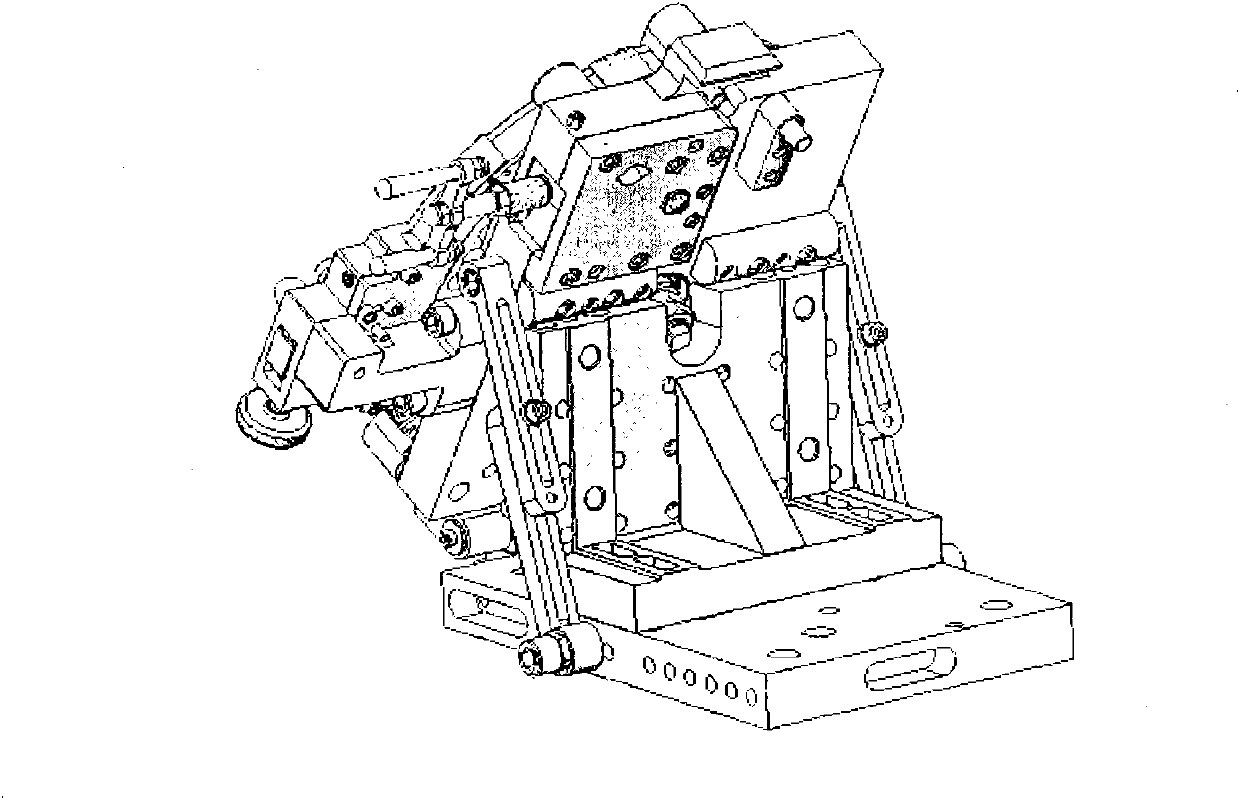

[0032] like figure 1 , figure 2 , image 3 As shown, an integrated platform for combined fixtures includes: lower table 1, angle iron support 2, upper table 3, indexing system 4, clamping system 5, fine-tuning system 6, turbine transmission system 7, tensioning system 8, cutting Side axis 9, hinge system 10, angle spacers 11, etc.

[0033] The lower deck 1 is a rectangular rigid plate structure, and at least one row of pin holes and threaded holes parallel to each other are arranged on one side plane; the pin holes and the threaded holes are arranged parallel to each other; the section of each pin hole is cylindrical and not Through, its round hole can just accommodate the size of a live pin assembly, so that the protruding part can be connected with the support member 2 after the live pin assembly is embedded in the round hole.

[0034] At least one row of threaded holes parallel to each other is provided on one side plane of the lower deck 1 and is symmetrical along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com