Display substrate and preparation method thereof, and display panel

A technology for display substrates and display areas, which is used in the manufacture of semiconductor/solid-state devices, organic semiconductor devices, electrical components, etc., can solve the problems that the yield cannot be further improved, the limited design structure, etc., to improve the design thickness and flatness, Improve the effect of encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

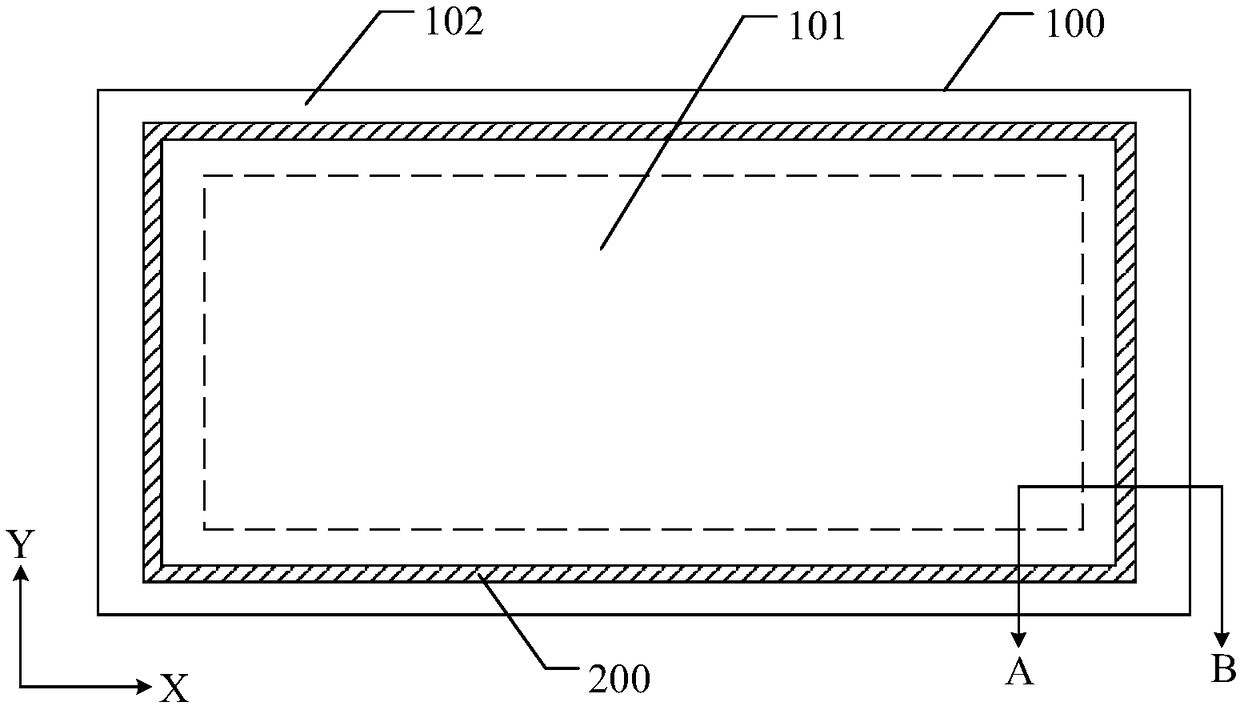

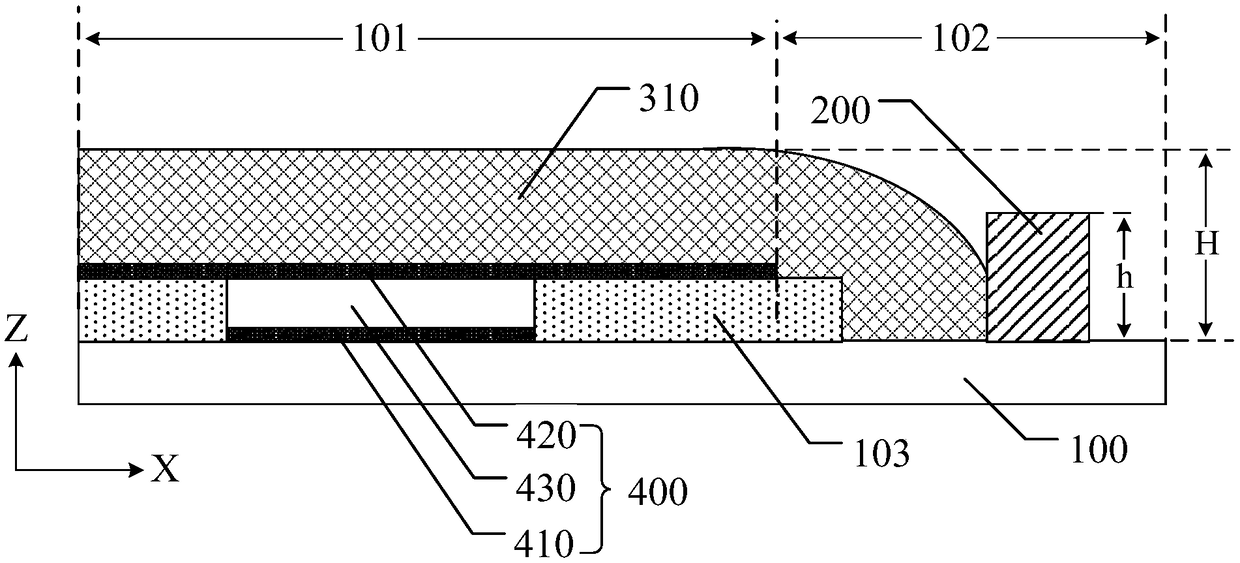

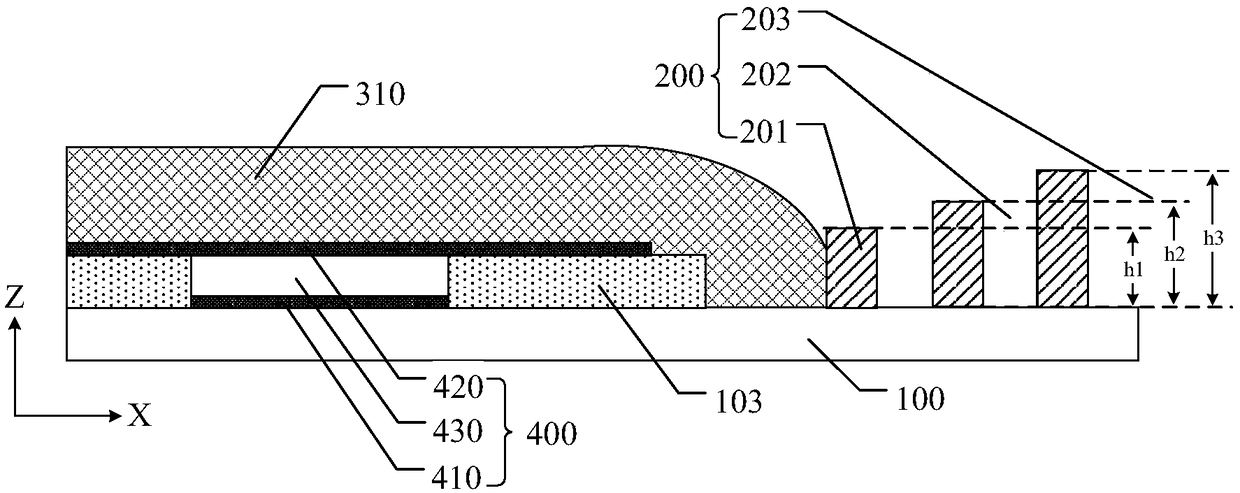

[0098] At least one embodiment of the present disclosure provides a method for preparing a display substrate, including: providing a base substrate, defining a display area of the display substrate to be formed on the base substrate and a non-display area located around the display area; Forming at least one barrier dam on the base substrate in the display area; applying a first encapsulation material on the base substrate in the display area; and curing the first encapsulation material to form a first encapsulation layer, at least one of the barrier dams facing the first encapsulation layer One side thereof is liquid-repellent relative to the first encapsulating material before curing. In the display substrate obtained by the above preparation method, the barrier dam can prevent the overflow of the first encapsulation material used to obtain the first encapsulation layer, thereby improving the flatness of the first encapsulation layer, and making the display substrate can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com