Thin-film packaging structure, thin-film packaging method and display panel

一种薄膜封装、显示面板的技术,应用在半导体器件、电气元件、电路等方向,能够解决易断裂、有机发光装置无法工作、OLED器件发光性能下降等问题,达到提高封装效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation, structure, features and functions of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

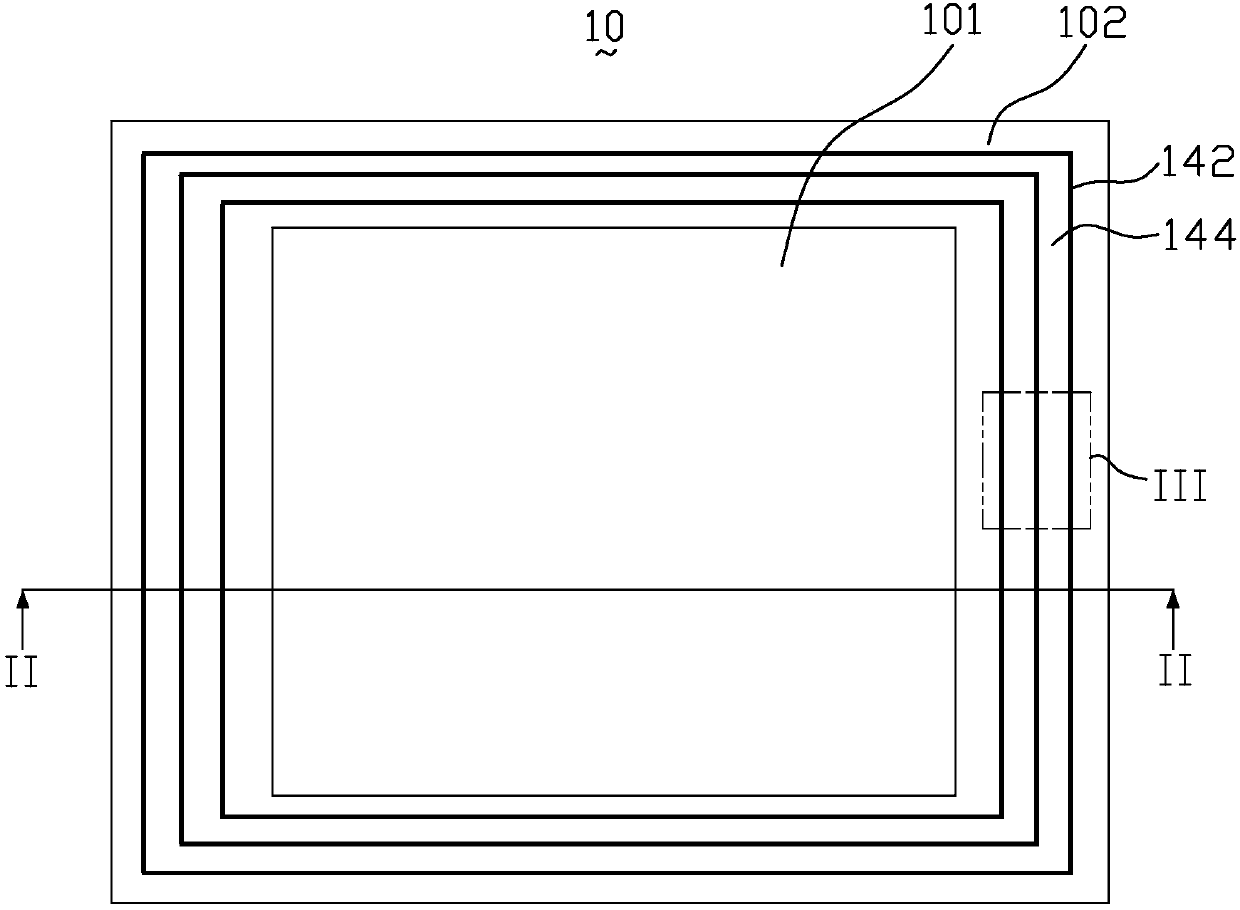

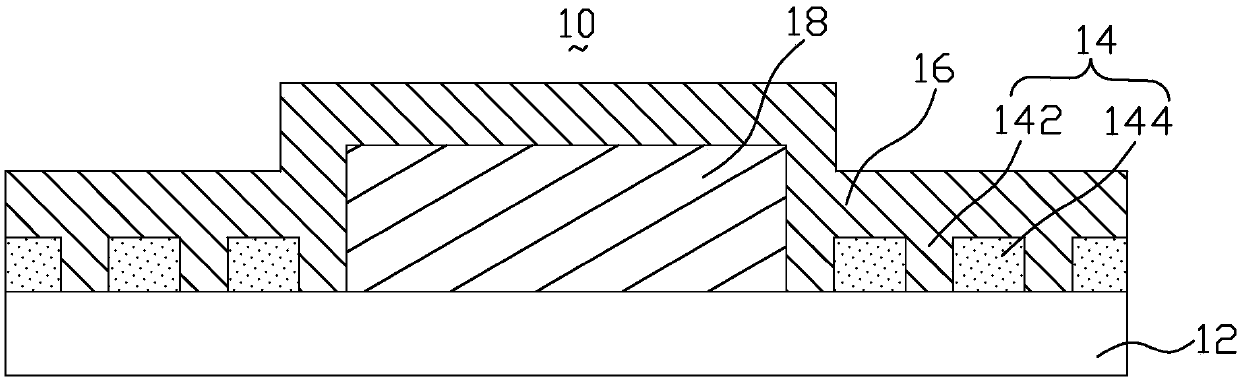

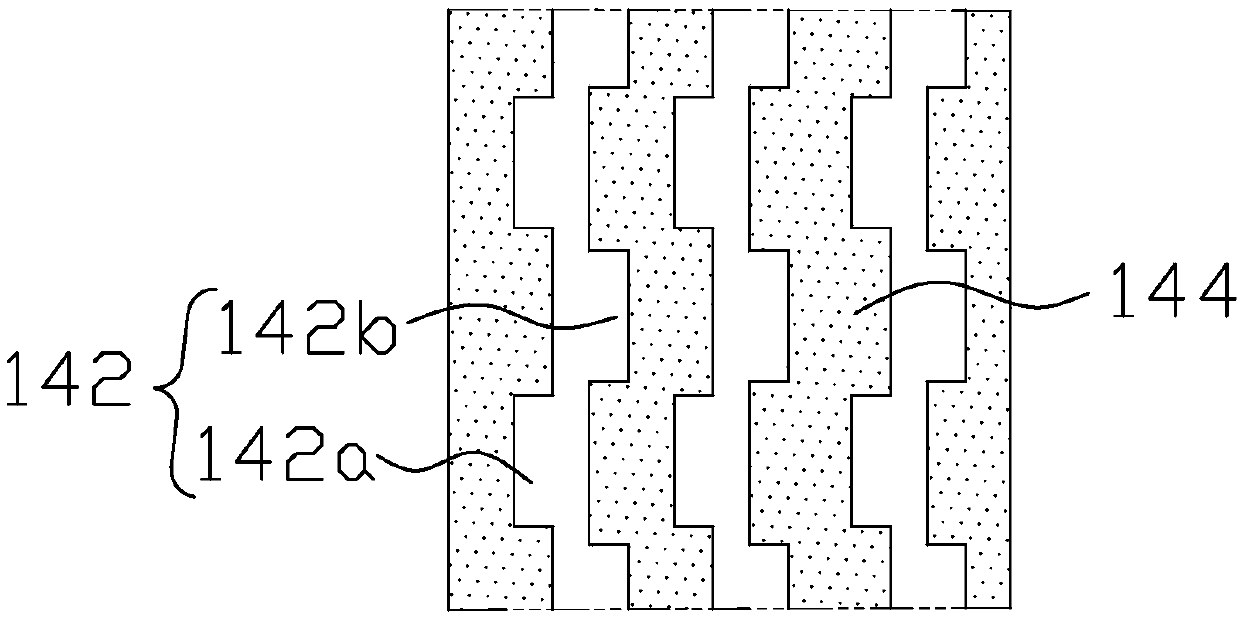

[0031] figure 1 It is a schematic top view structure diagram of the display panel provided by the present invention. figure 2 yes figure 1 A schematic cross-sectional view along line II-II. Such as figure 1 and figure 2 As shown, the present invention also provides a display panel 10 , including a base substrate 12 , and the base substrate 12 is divided into a display area 101 and a non-display area 102 surrounding the display area 101 . A light emitting device 18 is disposed on the display area 101 of the base substrate 12 , and an encapsulation film layer 16 is covered on the non-display area 102 and the light emitting device 18 . A thin film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com