System and method for machine vision-based robot sorting

A machine vision and sorting system technology, applied in the field of intelligent robots, can solve the problems of inconvenient operation, long research and development cycle, poor portability, etc., and achieve the effect of reducing production costs, high openness, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

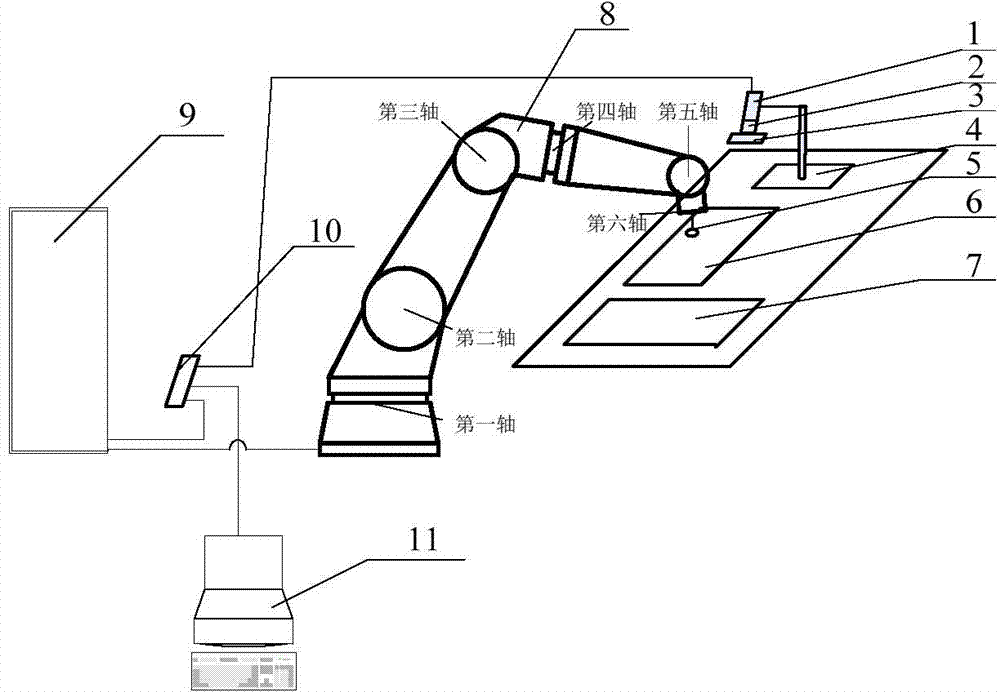

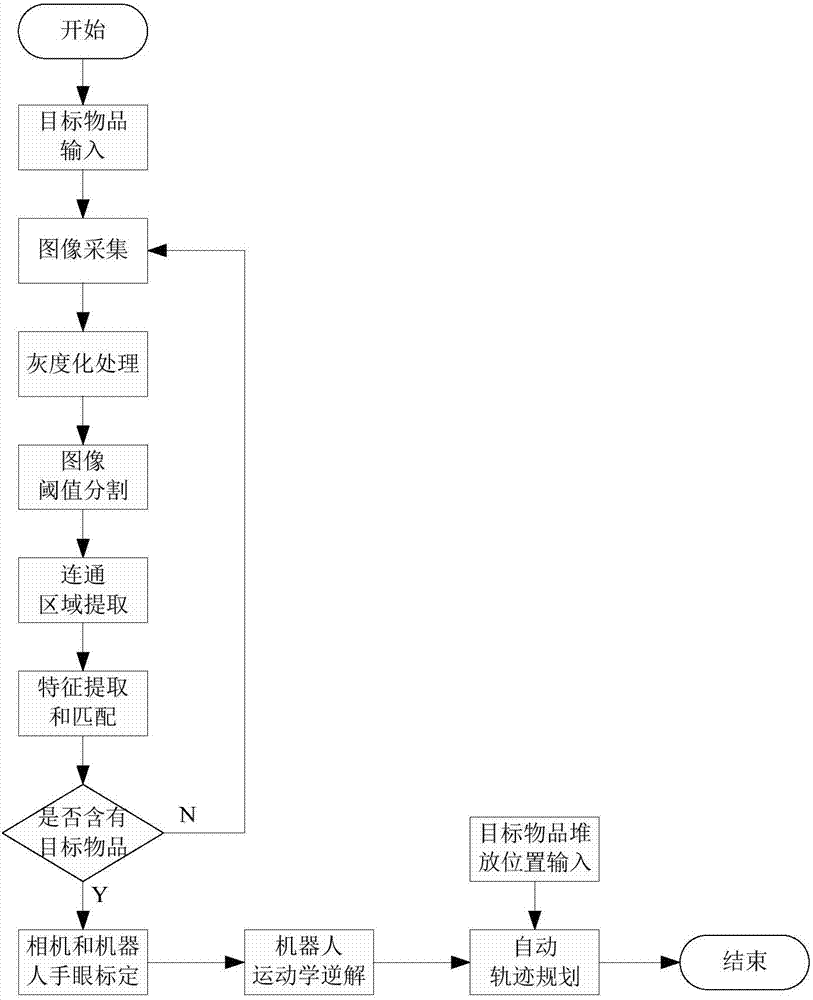

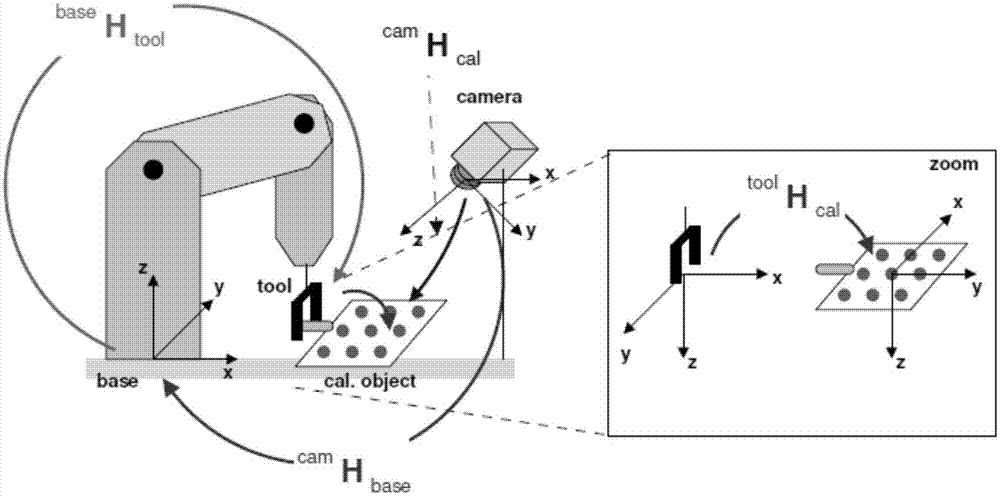

Method used

Image

Examples

Embodiment 1

[0104] In the area 6 of the items to be sorted, randomly scatter some areas with an area of about 16mm 2 , round vitamin B tablets, using this robot sorting system based on machine vision to complete the sorting of scattered tablets, the specific steps are as follows:

[0105] 1) Select and input the characteristics of scattered vitamin B pills, and determine that the target item to be sucked is vitamin B pills.

[0106] Create a new target item vitamin B tablet in the interactive interface, and input it according to the order of the features, select the shape as a circle, and fill in the area as 16mm 2 , Fill in the allowable error ±5%, confirm and store.

[0107] 2) Use an industrial CCD digital camera to collect scattered vitamin B tablets, and after obtaining the overall image, transmit the image data information to the industrial computer through Ethernet.

[0108] 3) Use an image processing program to Figure 4 The image in (a) is processed by threshold segmentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com