System and method for fast precise measurement and total factor data acquisition of high speed railway

A high-speed railway, precision measurement technology, applied in the direction of railway vehicle shape measuring instrument, measuring point marking, railway car body parts, etc., can solve the problems of discrete observation value and high cost, and achieve the effect of high system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

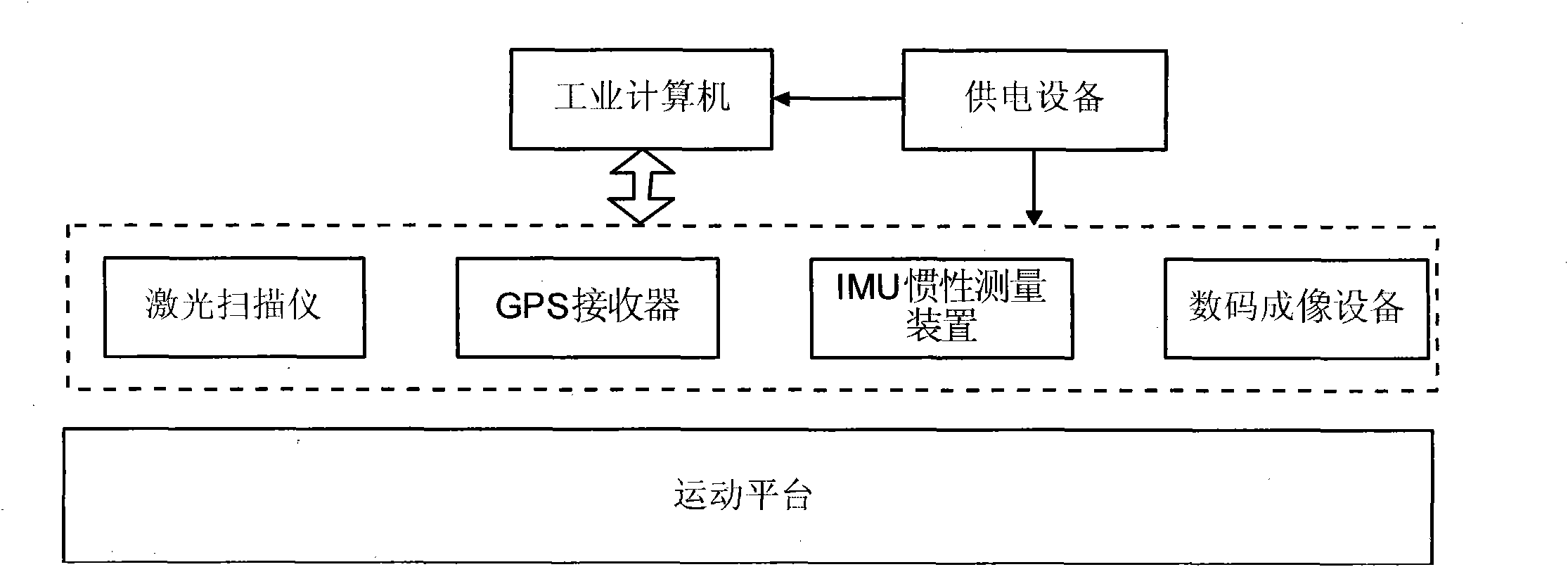

[0019] figure 1 It is a system schematic diagram of the high-speed railway mobile precision measurement system of the present invention. The system consists of a laser scanner 1 , a digital imaging device 2 , a GPS receiver 3 , an IMU inertial measurement unit 4 , an industrial computer 5 and a power supply unit 6 . The power supply device 6 provides power guarantee for the laser scanner 1 , the digital imaging device 2 , the GPS receiver 3 , the IMU inertial measurement device 4 , and the industrial computer 5 . Laser scanner 1, digital imaging equipment 2, GPS receiver 3, IMU inertial measurement device 4 are controlled by industrial computer 5. The system is installed on a moving platform 7. During the movement, the laser scanner 1 emits a laser beam and receives the laser pulses reflected by natural objects, and the digital imaging device 2 takes images of the high-speed railway track, roadbed and surrounding features. The GPS receiver 3 and the IMU inertial measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com