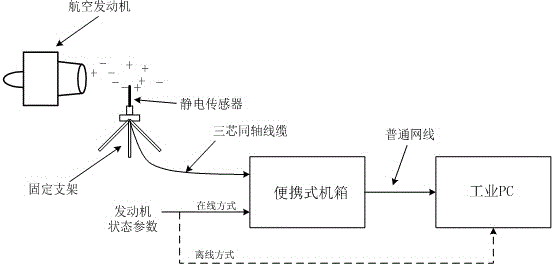

Portable failure detection system and method for aero-engine gas path component

A technology for aero-engines and gas circuit components, which is applied in the field of fault detection systems for portable aero-engine gas circuit components, can solve problems such as abnormal exhaust static signals, changes in the overall static charge level of exhaust gas, and influence on normal tissue combustion, etc., achieving low system cost, Ease of implementation and safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

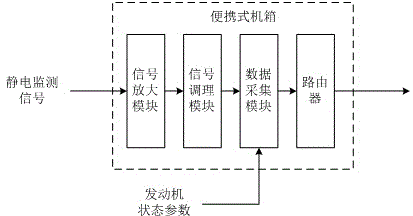

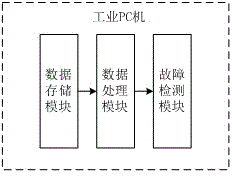

Method used

Image

Examples

Embodiment

[0045] This method is illustrated with the help of data collected from a certain engine test run. Firstly, the electrostatic signals and fuel flow in each steady state collected by a test run are analyzed. According to the exhaust static signal given by formula (1), the RMS value of the electrostatic signal is fitted with The change trend of fuel flow, such as Figure 4 shown. Under normal circumstances, the RMS value of the static signal should fluctuate within a certain range centered on the baseline. If it deviates too much, it indicates that the static charge level in the gas circuit has a significant change under the same fuel supply condition, which is usually It is caused by the sudden failure of air circuit components or the inhalation of foreign objects. Failures in the combustion chamber, such as carbon deposits in the nozzle and poor combustion organization, are likely to cause a significant increase in soot particles in the exhaust gas, resulting in a long-term de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com