Robot for cleaning metal pipeline by laser light

A metal pipeline and laser cleaning technology, applied in the field of robotics, can solve problems such as being unsuitable for metal pipeline cleaning, and achieve the effects of high average power and peak power, narrow pulse width, and high repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

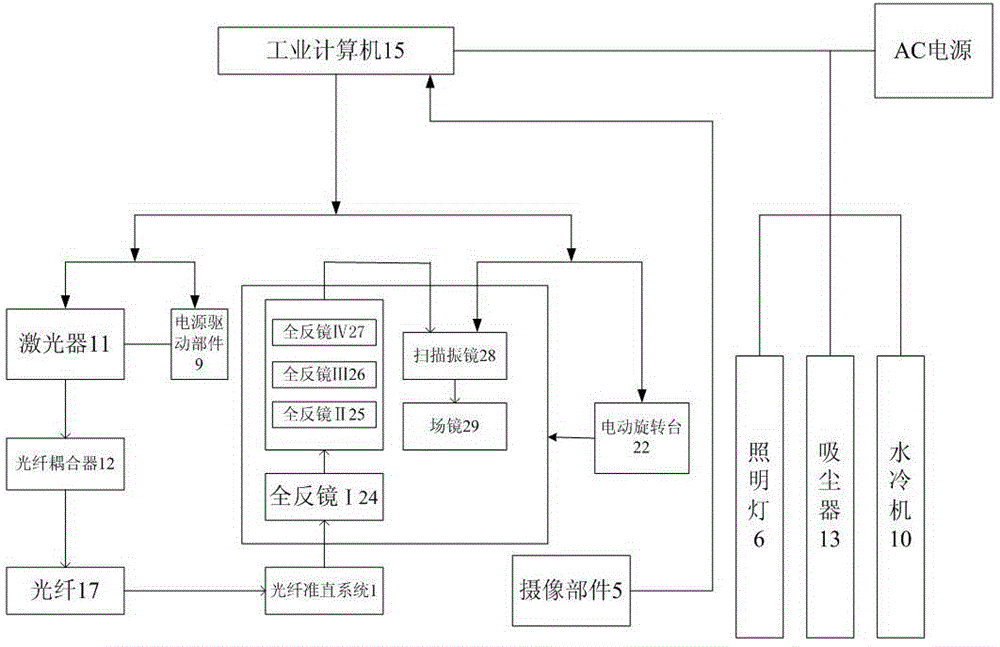

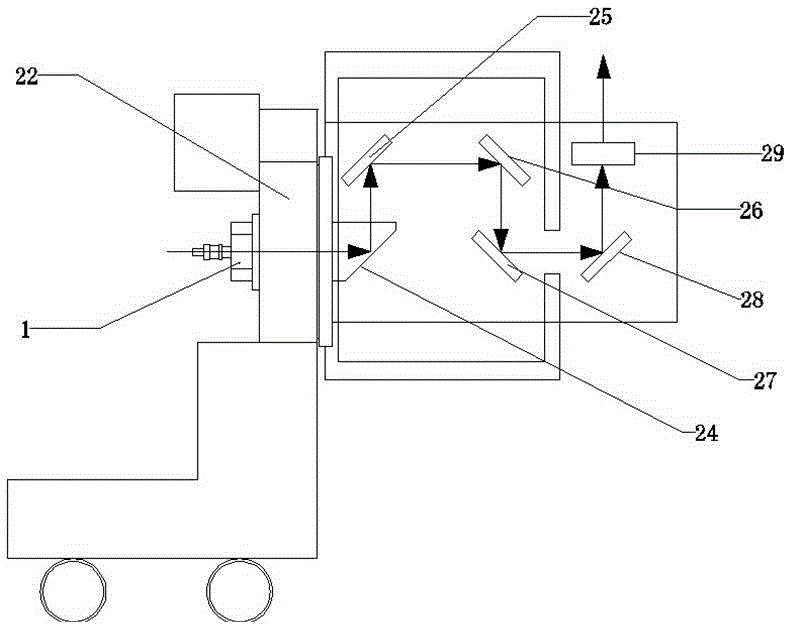

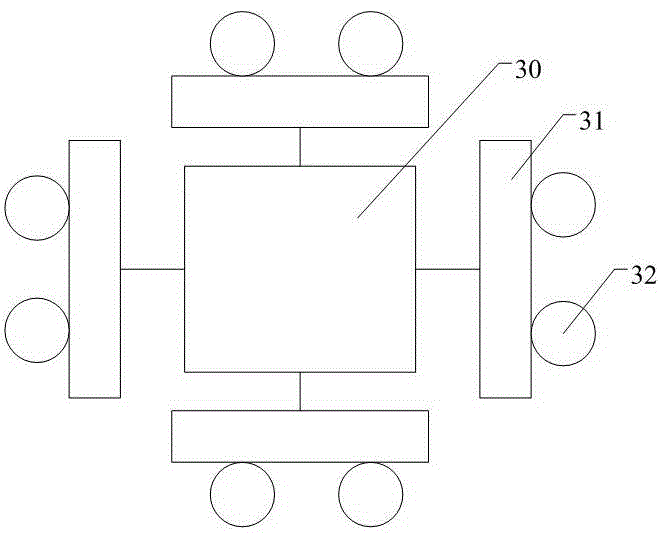

[0052] figure 1 It is a structural block diagram of a robot that adopts a laser to clean metal pipelines in the present invention. figure 2 It is a structural schematic diagram of the laser output part in the present invention, and the arrow in the figure indicates the direction of the optical path of the laser. image 3 It is a structural block diagram of the dust suction mechanism in the present invention. exist Figure 1-Figure 3 Among them, the robot using laser to clean metal pipes of the present invention includes a wheeled trolley, connecting parts, and a cabinet. Wherein, the wheeled trolley is provided with a laser output component, an imaging component 5, and a dust suction mechanism.

[0053] The laser output component includes an optical fiber collimation system 1 and a rotation auxiliary component; an electric rotation table 22, an electric translation table, and a total reflection mirror I24 are arranged on the rotation auxiliary component. The electric tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com