Welding robot with automatic correction function and welding method employing same

A welding robot and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of high versatility, easy-to-understand methods, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

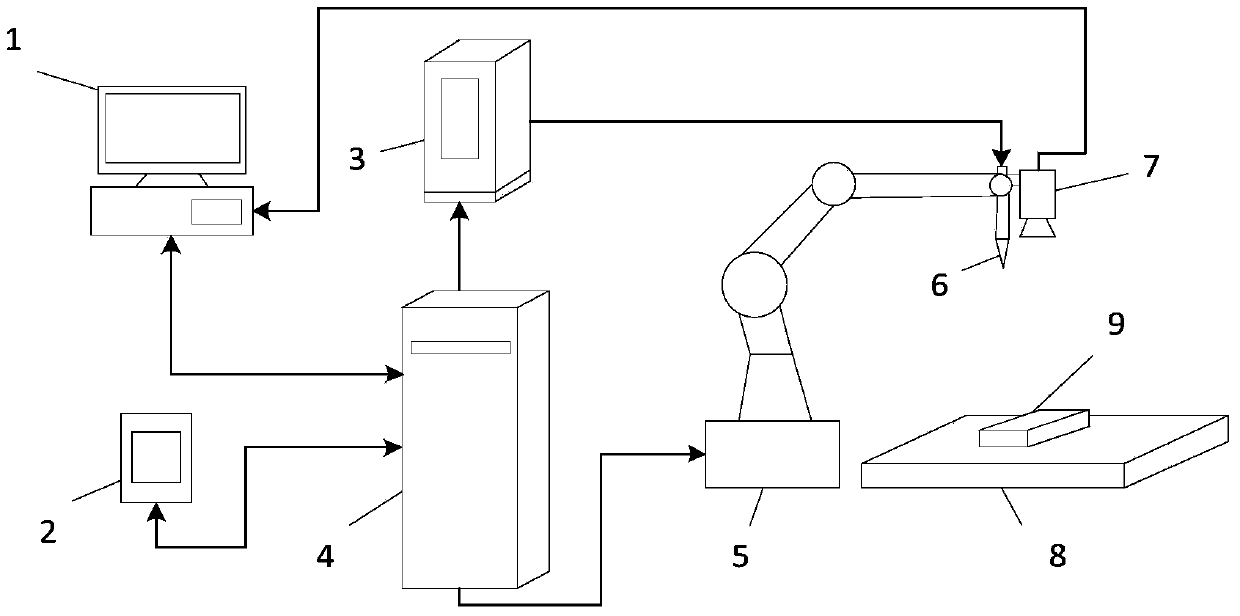

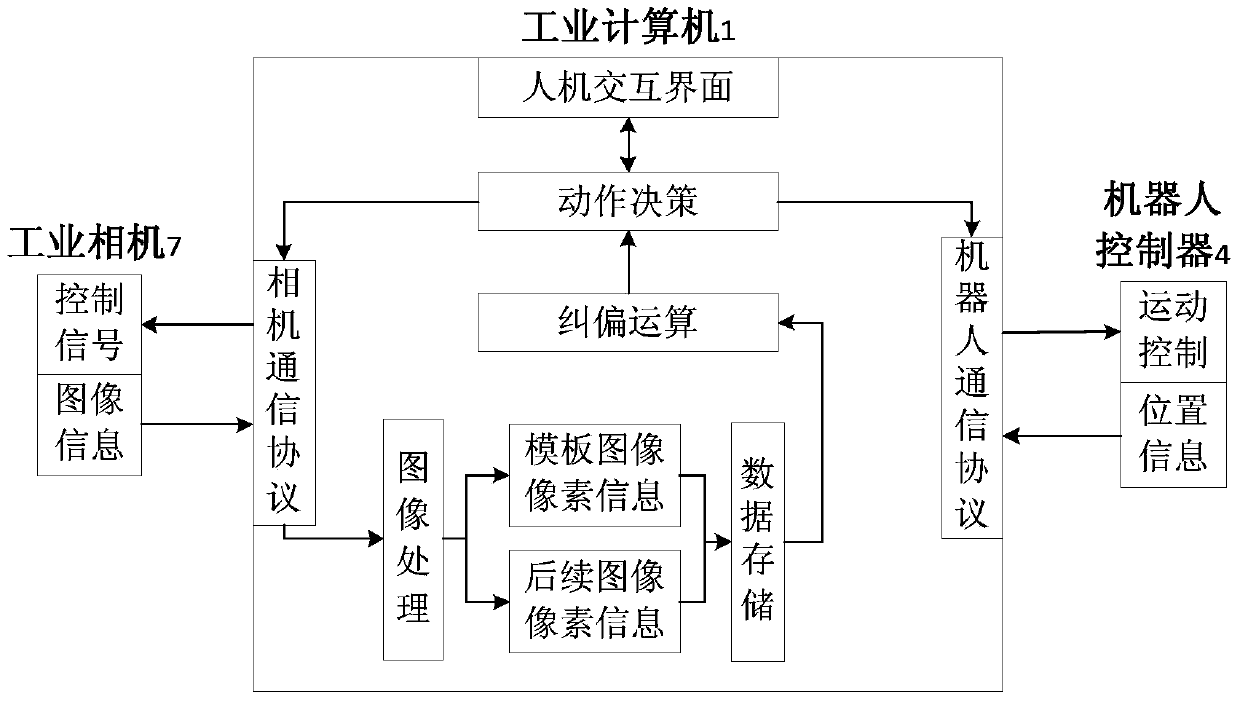

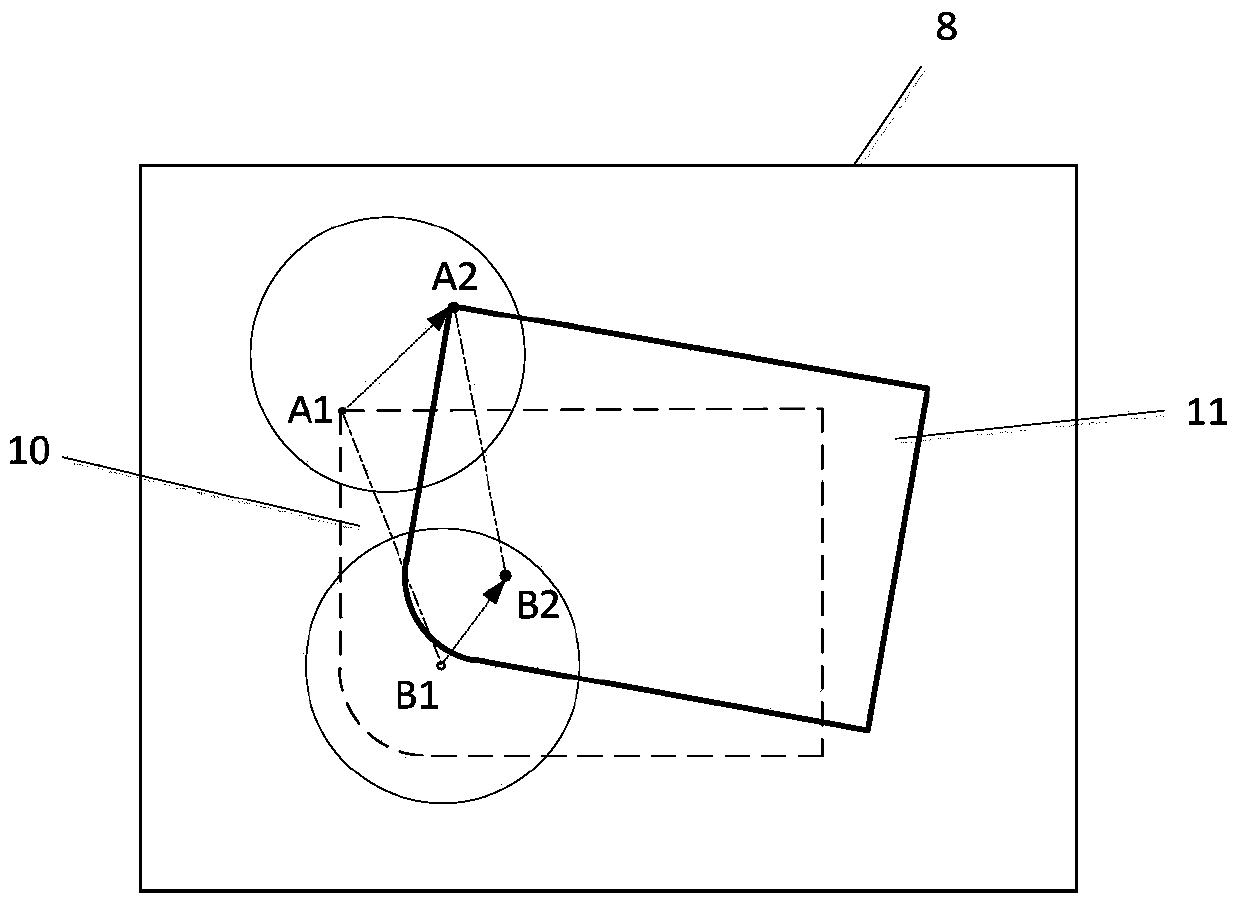

[0019] This embodiment is described in conjunction with the accompanying drawings. The system of this embodiment is composed of an industrial computer 1, a hand-held teaching device 2, a welding power supply 3, a robot controller 4, a robot 5, a welding torch 6, an industrial camera 7, and a welding platform 8. The industrial The motion data input and output ends of the computer 1 are connected with the motion data output and input ends of the robot controller 4, the control data input and output ends of the hand-held teaching pendant 2 are connected with the control data output and input ends of the robot controller 4, and the robot The power control output end of the controller 4 is connected to the control input end of the welding power supply 3, the motion control signal output end of the robot controller 4 is connected to the motion signal input end of the robot 5, and the power output end of the welding power supply 3 is connected to the welding torch 6 The power input en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com