System and method for numerical control (NC) workbench error self correction based on machine vision

A technology of machine vision and workbench, which is applied in the field of self-calibration system, can solve problems such as difficulty in guaranteeing accuracy, cumbersome correction work, and inability of grating or encoder to perform effective compensation, so as to improve positioning accuracy, system positioning accuracy, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

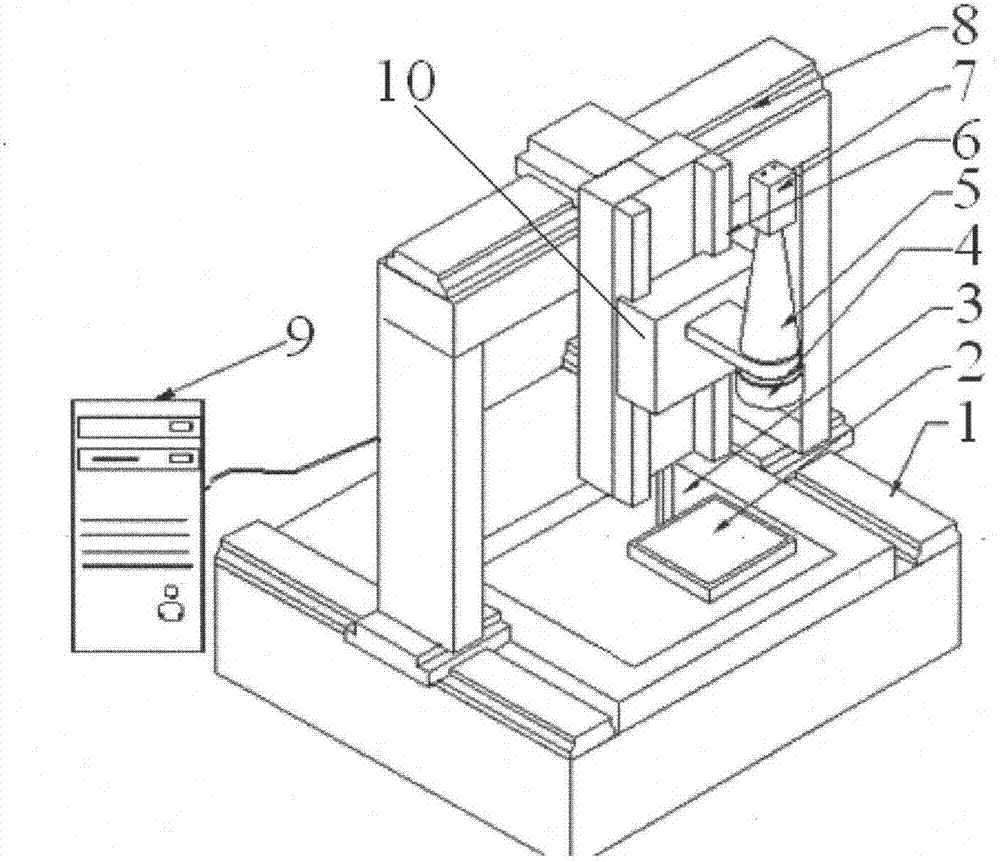

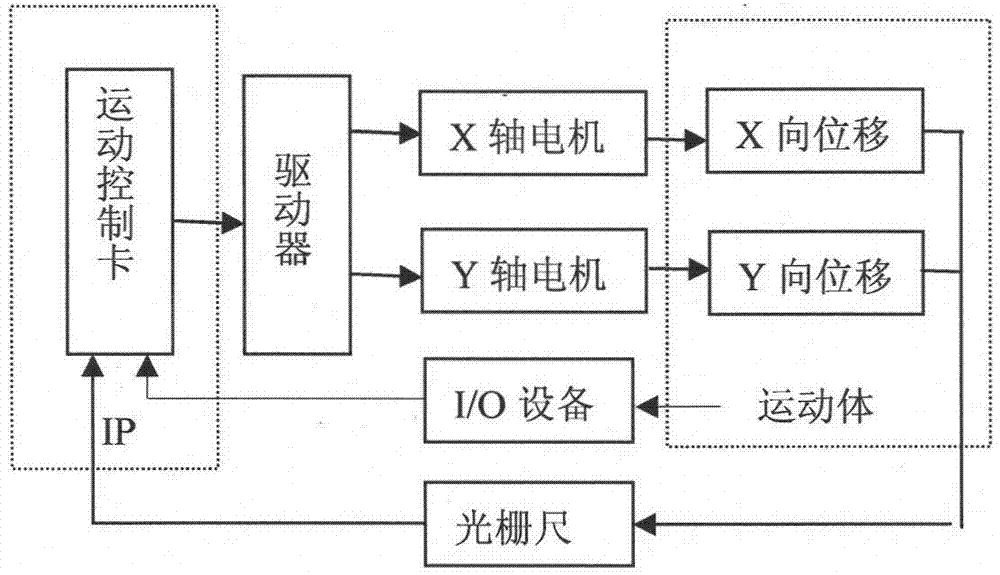

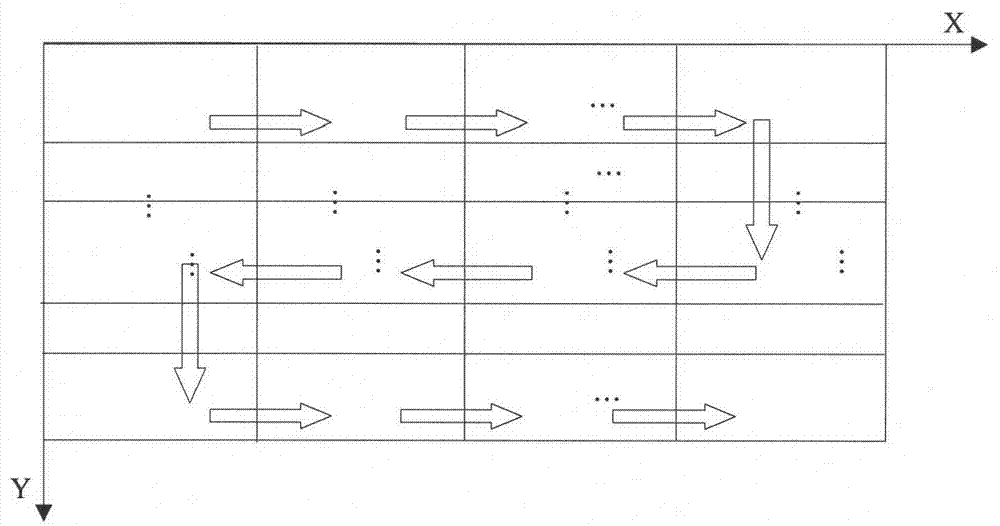

[0037] figure 1 A schematic diagram of a CNC workbench error self-correction system based on machine vision provided by the present invention. The machine vision-based CNC workbench error self-correction system includes an X, Y, Z three-coordinate motion workbench, a moving body 10 is placed on the X, Y, Z three-coordinate motion workbench, an image acquisition system is installed on the motion body 10, and objects with rich surface or contour features are placed on the stage 3 of the X, Y, Z three-coordinate motion workbench. The calibration board 2 is used by the industrial computer 9 to analyze and calculate the sequence images collected by the image acquisition system to obtain the positioning error of each coordinate on the X-Y plane.

[0038] The X, Y, Z three-coordinate motion workbench includes a stage 3, and the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com