Machine visual on-line detection method and equipment for tank cover quality in high-speed production line

A technology of machine vision and testing equipment, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of poor working environment, inability to grasp, lack of glue in the glue area, etc., and achieve fast detection speed, compact structure, simple and compact. Effect

Inactive Publication Date: 2010-08-11

HUNAN UNIV

View PDF6 Cites 56 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The defects of manual detection are: 1. The detection speed is slow and the efficiency is low, which cannot meet the needs of high-speed automatic production lines; 2. The detection accuracy is low, the detection quality is affected by human factors, and the error and false detection rate are high; Poor environment; 4. Waste of human resources, unable to meet the current industrial modernization management requirements

There is still the problem of artificial pollution in the manual quality inspection of metal material products

For the high-speed automatic production line, after the can lids go through the process of capping, crimping and gluing, the main quality problems include: 1. Pollution, damage, and scratches on the surface of the can lids; 2. Lack of glue in the glue area, No glue; 3. Multiple can lids overlap

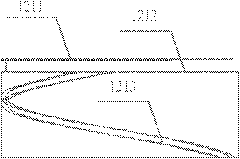

Since the can lid is made of metal, its quality criteria include cleanliness detection, shape detection, and width detection. Therefore, the detection scheme based on photoelectric sensors cannot be realized. Only machine vision methods can be used to perform quality detection by acquiring images of the detection objects.

Compared with conventional machine vision inspection systems, the machine vision inspection of metal products (for can lids) has the following problems: 1. Imaging is more difficult than conventional transparent materials; 2. The shape of can lids is special and cannot be grasped by conventional mechanical devices , transmission and removal; 3. The object of tank quality inspection is multiple areas of the tank, which is different from the conventional overall inspection of objects; 4. The characteristics of metal products are not obvious, and the detection error rate is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

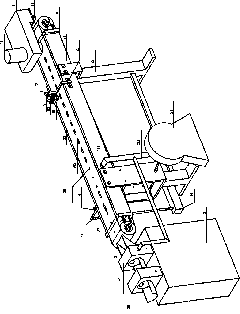

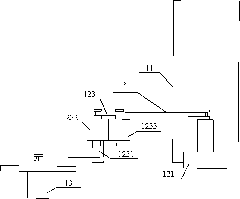

The invention discloses machine visual on-line detection method and equipment for the tank cover quality in a high-speed production line. The method comprises the following steps of: in an automatic production line, separating tank covers to be detected into single tank covers moving on a delivering device; imaging the tank covers by using an imaging system at a high speed when the tank covers move to a detection station of the delivering device; transmitting an acquired tank cover image to an industrial computer for processing; carrying out quality detection on a plurality of detection areas to generate quality detection signals; eliminating unqualified products by using an eliminating device positioned at the eliminating station of the delivering device; making the qualified products continuously move on the delivering device and pass through a shaping device and outputting the qualified products in sequence. The equipment comprises a cover feeding device, the delivering device, the shaping device, the eliminating device, the imaging system, the industrial computer and an electric control system. The invention has the advantages of simple and compact structure, low cost, simple and convenient operation, high precision, high detection speed and the like.

Description

Machine vision online inspection method and equipment for can lid quality on high-speed production line technical field The invention mainly relates to the field of automatic detection equipment on a production line, in particular to a method and equipment for detecting the quality of can lids on a production line. Background technique In the high-speed automatic production line, how to quickly and accurately inspect the quality of products and quickly remove unqualified products is an important technical problem directly related to product quality. At present, most product quality inspection and classification mainly rely on manual methods, especially for the quality inspection of metal products. The defects of manual detection are: 1. The detection speed is slow and the efficiency is low, which cannot meet the needs of high-speed automatic production lines; 2. The detection accuracy is low, the detection quality is affected by human factors, and the error and false detec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/88G01N21/84G01N21/13G01B11/00G01B11/02B07C5/342

Inventor 王耀南陈铁健张辉段峰葛继周博文杨双熊路马波侯备

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com