Optical fiber sensor based on zeolite molecular sieve film-plating microresonator and preparation method thereof

A technology of zeolite molecular sieve membrane and zeolite molecular sieve, which can be applied to multi-layer core/cladding optical fibers, cladding optical fibers, color/spectral characteristic measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

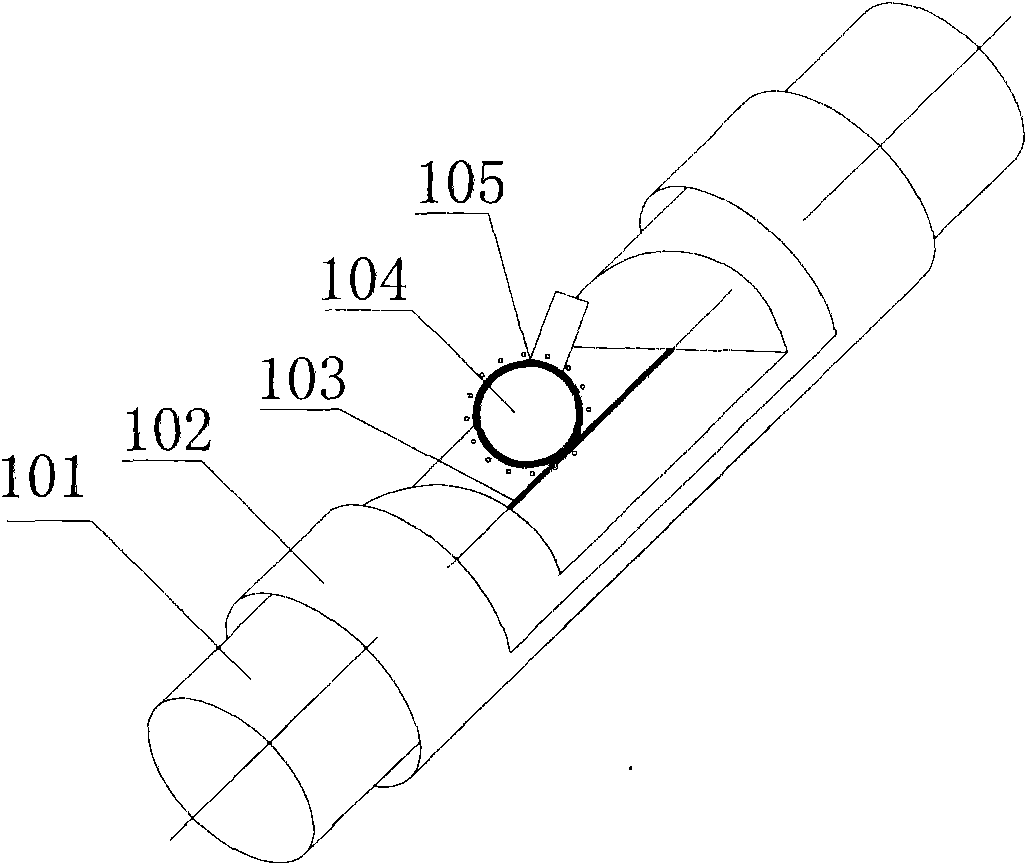

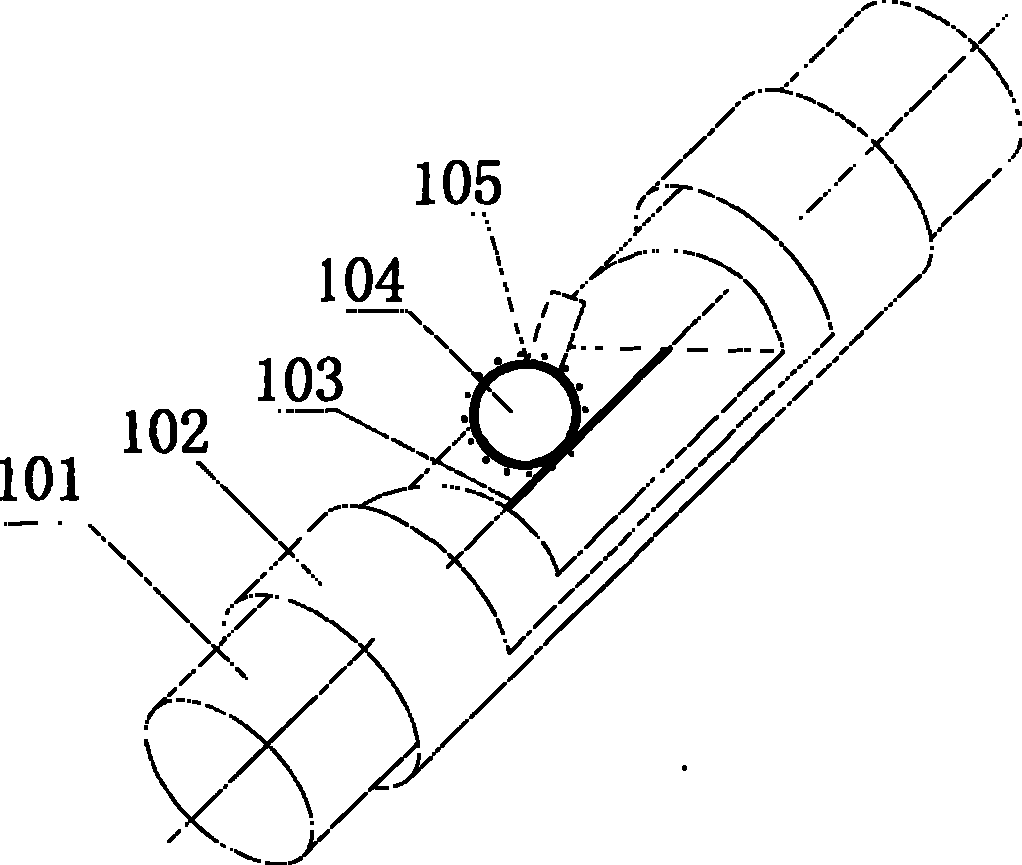

[0028] Take an ordinary optical fiber, peel off the protective layer of the middle part and expose the fiber cladding, use pulsed laser to melt the middle part of the fiber at high temperature, make the middle part appear tapered and gradually become thinner, control the drawing process so that the diameter of the thinnest part reaches After a few microns to pull off. Then continue to use the pulsed laser to locally melt the broken end of the optical fiber. Under the action of surface tension, the end of the optical fiber forms a more standard spherical shape, and the melting time is controlled. After cooling, a microsphere with a diameter of 50 microns with a fiber micro-handle is obtained.

[0029] Mix 6.56 ml of TPAOH (tetrapropylammonium hydroxide) solution, 15.3 ml of TEOS (tetraethyl tetrasilicate) solution and 30 ml of distilled water, and stir at 50° C. for 3 hours. A microresonator with an optical fiber micro-handle is placed in the mixed liquid and the mixed liquid i...

Embodiment 2

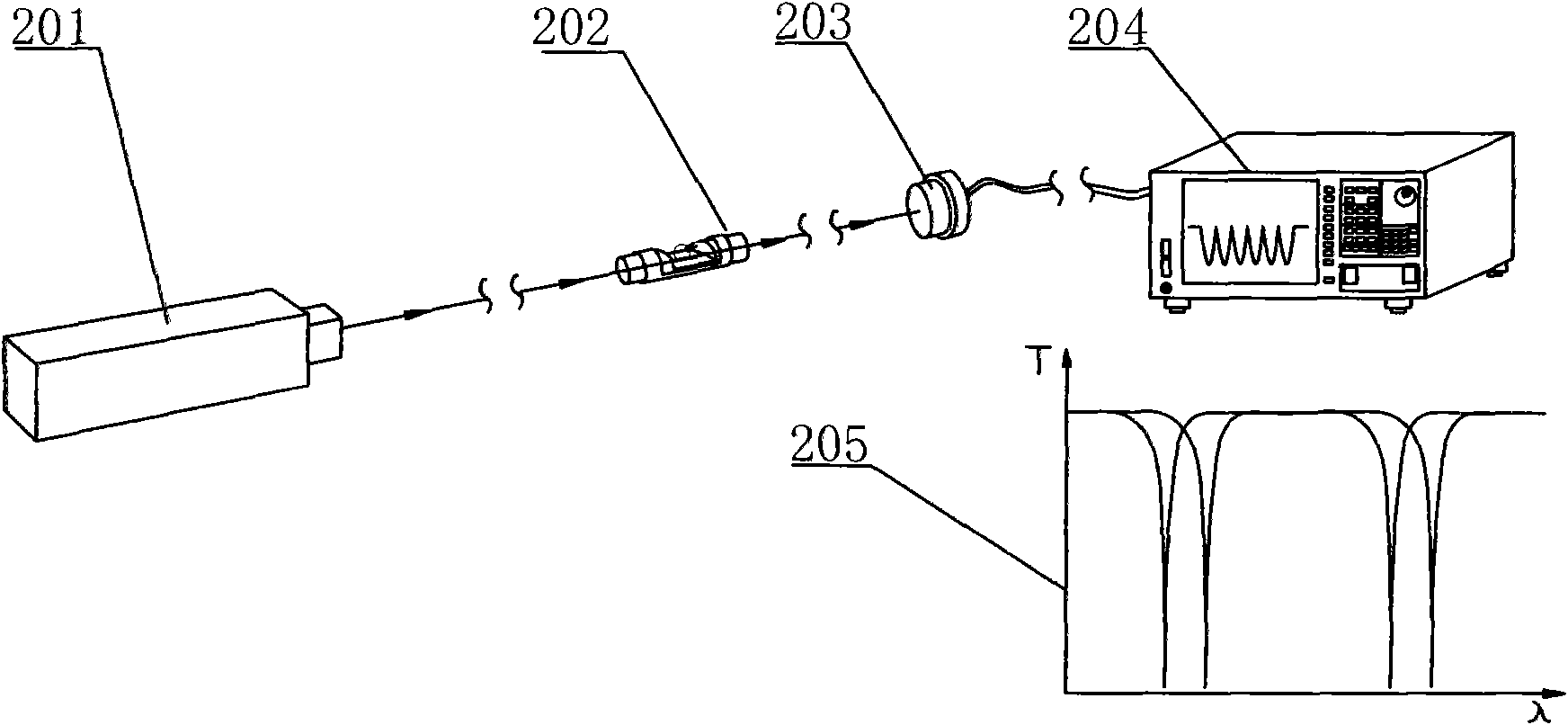

[0032] The experimental system device that uses the sensor of the present invention to detect the concentration of chemical and biomolecules in the environment is as figure 2 As shown: the ultra-high sensitivity miniature optical fiber sensor 202 based on the zeolite molecular sieve coating microresonator of the present invention is placed in the environment to be tested, when the incident light output by the laser light source 201 with a continuously changing wavelength enters the sensor 202 through coupling, due to the light Coupled into the microsphere resonator, some specific wavelengths of light form a whispering gallery mode in the microsphere resonator, the light output from the main fiber of the sensor 202 is received by the detector 203 and sent to the spectrometer 204 to obtain the absorption spectrum 205, The "transmittance-wavelength" curve of the absorption spectrum 205 will generate a series of resonant absorption bands, and the wavelengths corresponding to these...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com