Vertical structure light-emitting diode and production method thereof

A light-emitting diode, vertical structure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem that miniature light-emitting diodes have not been proposed, and achieve the effect of achieving light-emitting effect and improving light-emitting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as Figure 1~10 As shown, this embodiment provides a method for fabricating a vertical light-emitting diode, including the following process steps:

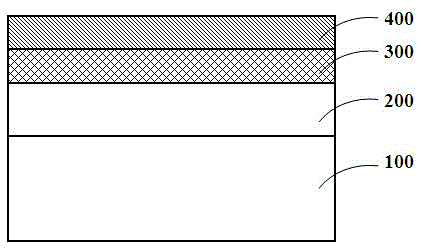

[0030] (1) if figure 1 As shown, a first substrate 100 is provided; in this embodiment, a light-emitting epitaxial layer is grown on the first substrate 100 by MOCVD (metal organic vapor deposition), and the light-emitting epitaxial layer includes a first epitaxial layer 200, a light-emitting layer 300 and a second epitaxial layer in sequence. 400.

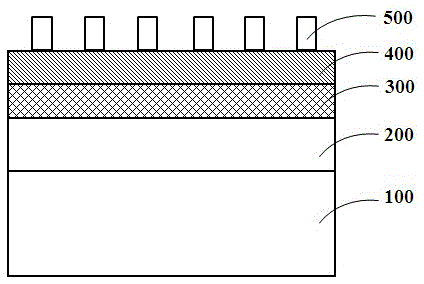

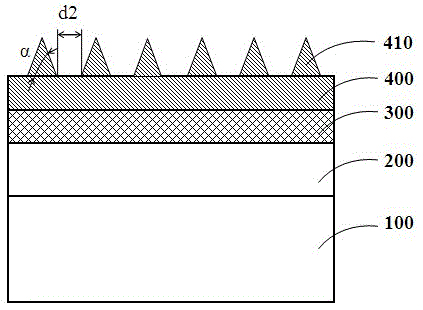

[0031] (2) if Figure 2~3 As shown, a plurality of second hexagonal pyramids 410 are formed on the surface of the second epitaxial layer 400 through an epitaxial process. Specifically, the epitaxial process for forming the second hexagonal pyramids 410 is as follows: using light on the surface of the second epitaxial layer 400 Resist opening mask, the photoresist of this embodiment adopts SU-8 photoresist opening mask, make SU-8 pattern, as etching barrier layer. The...

Embodiment 2

[0039] Such as Figure 7 As shown, the difference between this embodiment and embodiment 1 is that in step (6), the mask layer 500 uses SiO 2 or SiN x With increased etch selectivity, this embodiment is preferably SiO 2 , using the photomask process to fabricate patterned SiO 2 The layer corresponds to the position of the second hexagonal pyramid 410 . Using dry etching technique, etching is carried out in ICP inductively coupled plasma equipment. Carry out the first stage of etching first, etch away the photoresist layer and etch out a certain depth of SiO2 layer and epitaxial layer, the etching gas components used include: CHF 3 and Ar, where CHF 3 The ratio to Ar is 3:1~20:1, the power of ICP is 150W~170W, and the reaction time is 5min~10min. After the photoresist layer is etched, the second stage of etching is performed to etch away the SiO2 layer and the epitaxial layer. The etching gas used is: the etching gas used is Cl 2 and Ar, where Cl 2 The ratio of Ar to Ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com