Automatic sample warping machine and its warping method

A warping machine, sample technology, applied in the direction of warping machines, textiles and papermaking, manufacturing tools, etc., can solve the problem of insufficient warp yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

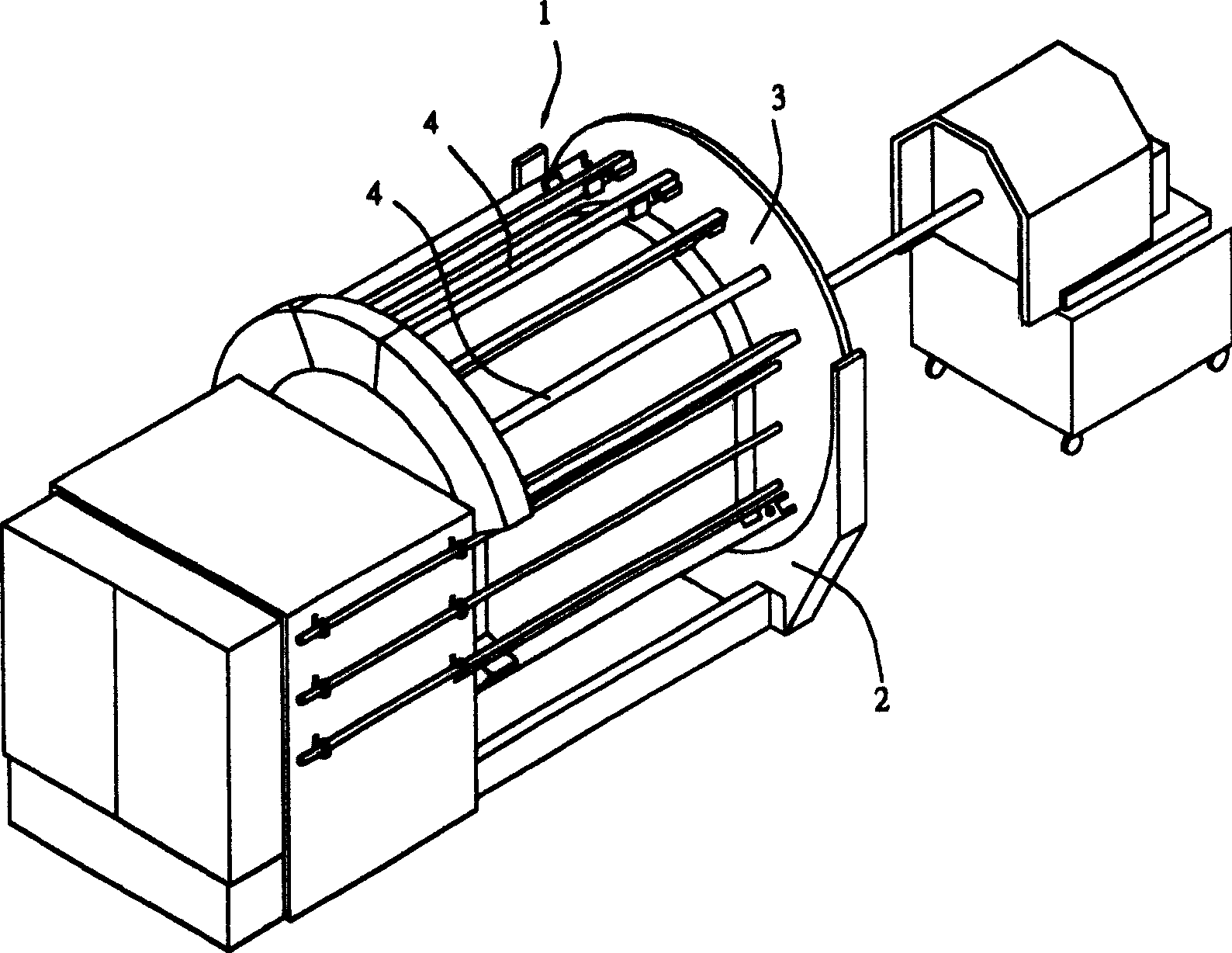

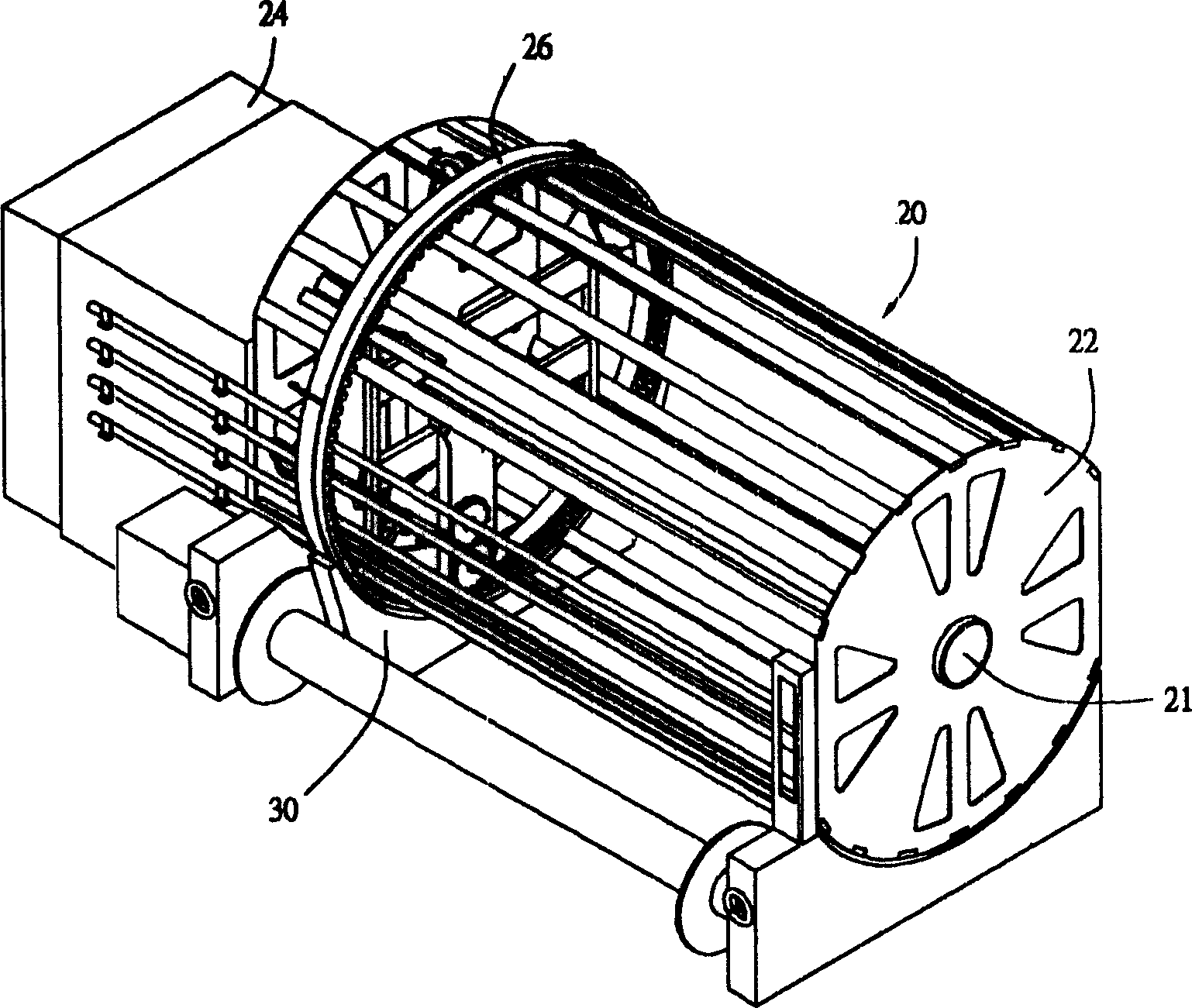

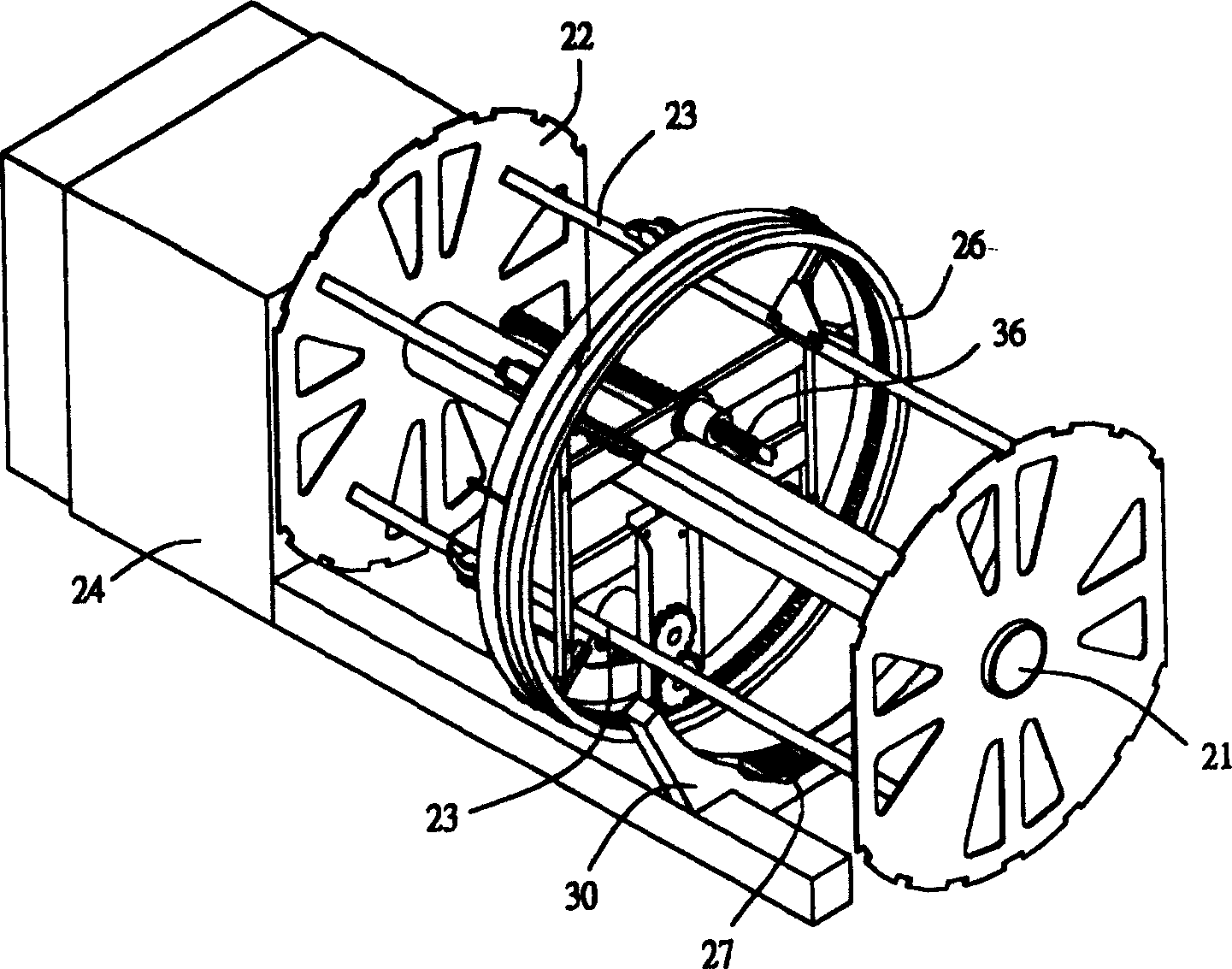

[0022] see figure 2 , image 3 Shown, the dissimilar or homogeneous yarns of the present invention are pulled out from a creel (not shown in the figure), and then pulled onto each yarn selector 27 of the yarn guide 30; wherein, whether it is the traverse wheel 26 or the The micro-moving wheels 28 all move in parallel on four auxiliary rods 23 mounted on the cylinder 22 .

[0023] Please also see Figure 4 , Figure 5 As shown, the present invention warps dissimilar or homogeneous yarns on the drum 22 by several yarn selectors 27 on a lead frame 30, which includes: a traverse wheel 26, the wheel surface of which is provided with a hook The yarn head 50 is used to hook the yarn drawn by the yarn selectors 27;

[0024] A first bracket group 32, which is erected in the traversing wheel 26, the first bracket group 32 has a plurality of auxiliary frames 45 and a driving mechanism, and the traversing wheel 26 is rotated by the driving mechanism;

[0025] A micro-moving wheel 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com