Composite material joint and preparation method thereof

A composite material and metal insert technology, applied in the aerospace field, can solve problems such as failure and underutilization of composite material designability, and achieve the effects of improving bearing capacity, improving connection reliability, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The method for preparing the above-mentioned composite material joint provided by the present invention comprises the following steps:

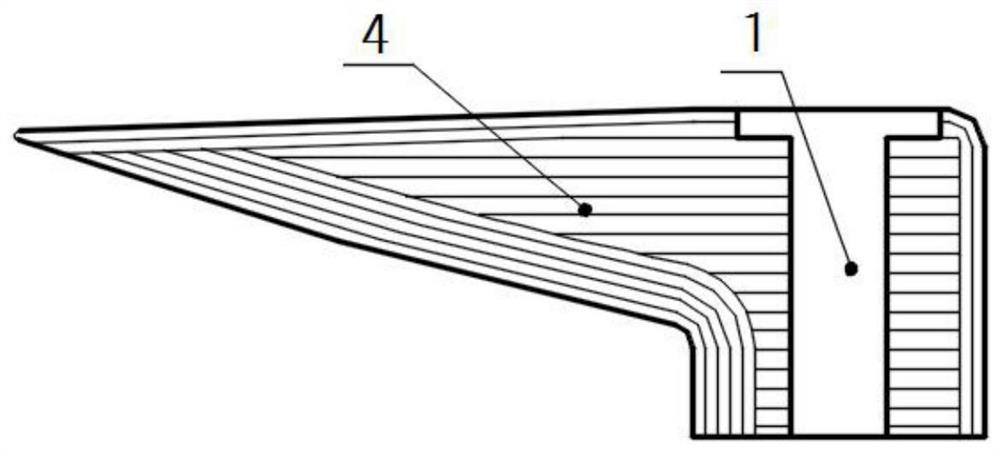

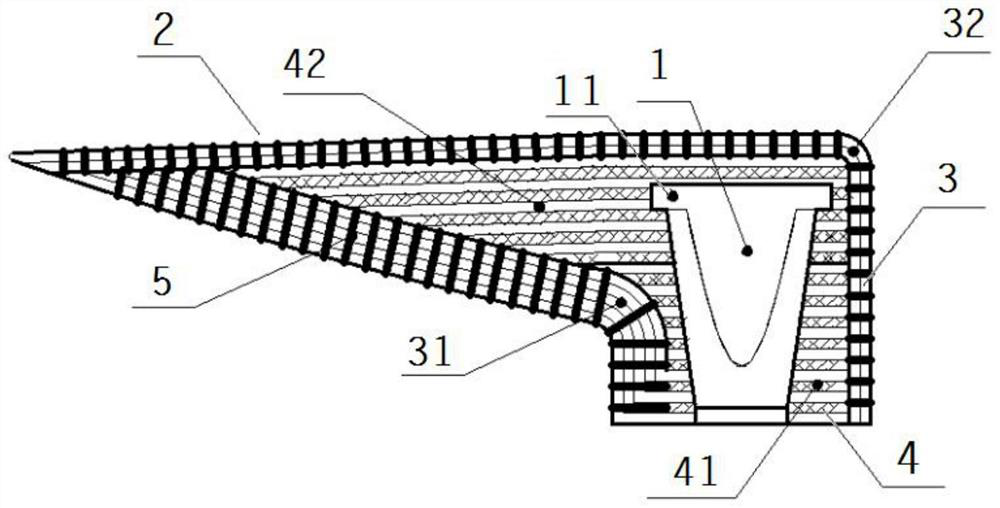

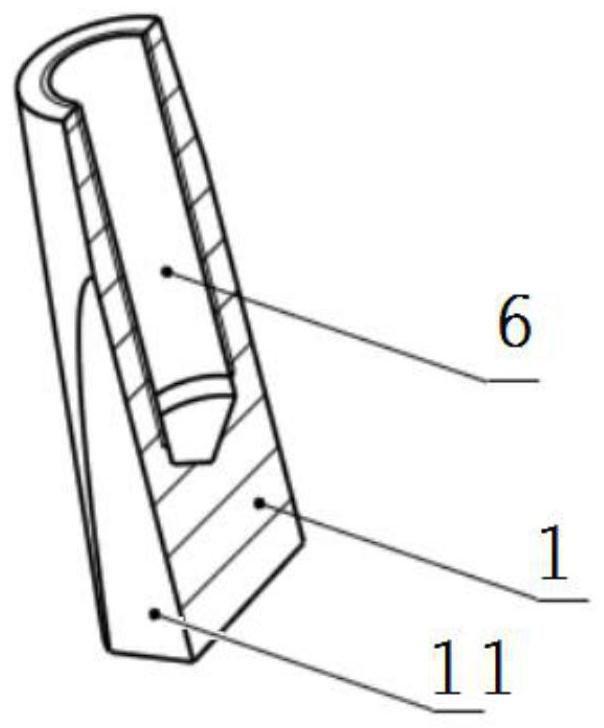

[0047] (1) Lay the material required for the skin 1 31 on the surface of the forming female mold of the composite material joint, pressurize; then lay the material required for the matrix 4, pressurize; finally lay the material required for the skin 2 32 piece, install the molded male mold for pre-compression;

[0048] (2) Disassemble the male and female molds, take out the pre-pressed composite material joint, and implant the micro-rod 5 into the first skin 31 and the second skin 32 respectively;

[0049] (3) Hoist the male and female molds to the hot press platform after closing the molds, arrange thermocouples and insulation layers around the molds, and pressurize and solidify;

[0050] (4) After the mold cools down and the pressure is relieved to a predetermined value, disassemble the mold, take out the prefabricated composite mat...

Embodiment 1

[0055] The invention provides a preparation method for a composite material joint, comprising the following steps:

[0056] (1) Mold preparation: Assemble the female and male molds for forming composite material joints, paste the release cloth, apply the release agent, and set aside.

[0057] (2) Lay-up material preparation: According to the composite material joint structure and division area, plan the ply material, then cut, number and reserve.

[0058] (3) Sheet laying and pre-pressing: Lay the prepared sheet in the female mold for composite joint forming, first lay the sheet required for the skin 1 31 on the surface of the female mold, and lay it with the busbar as the reference direction Then arrange a vacuum bag in the female mold to evacuate or install a pre-molded male mold to pressurize; then lay the required material or chopped premix for the matrix 4 on the skin one 31 and the surface of the female mold, the material or The short-cut premix is laid with the busba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com