Novel Co(OH)F lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of electrochemical performance research that has not been reported, and achieve the effects of promoting chemical reactions, high capacity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

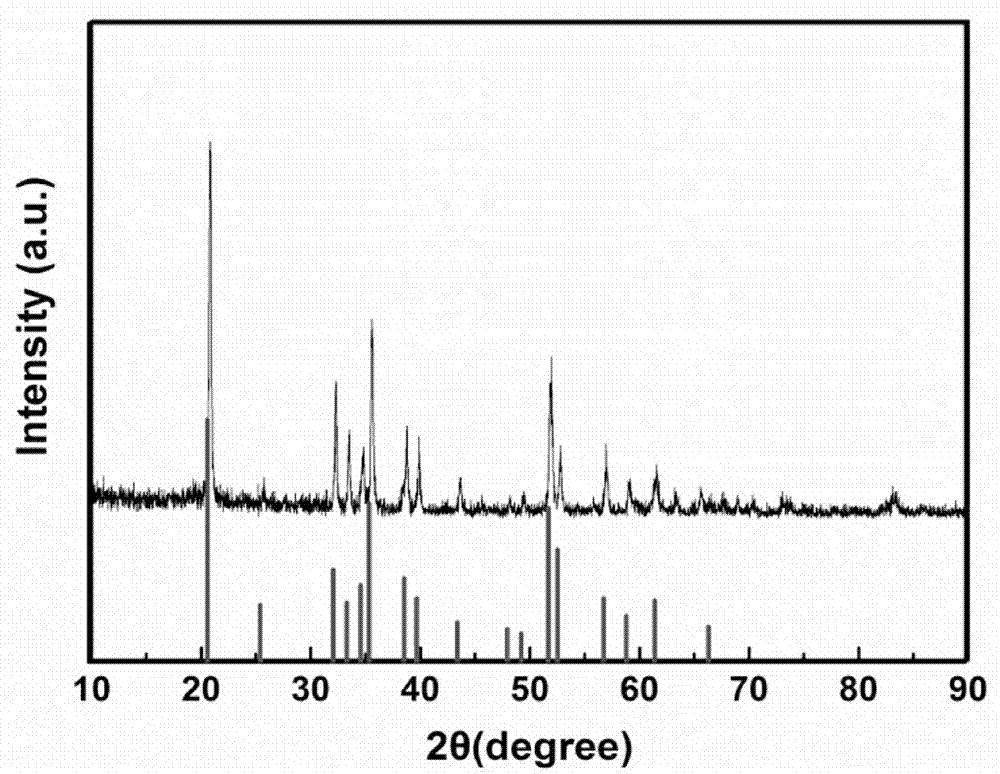

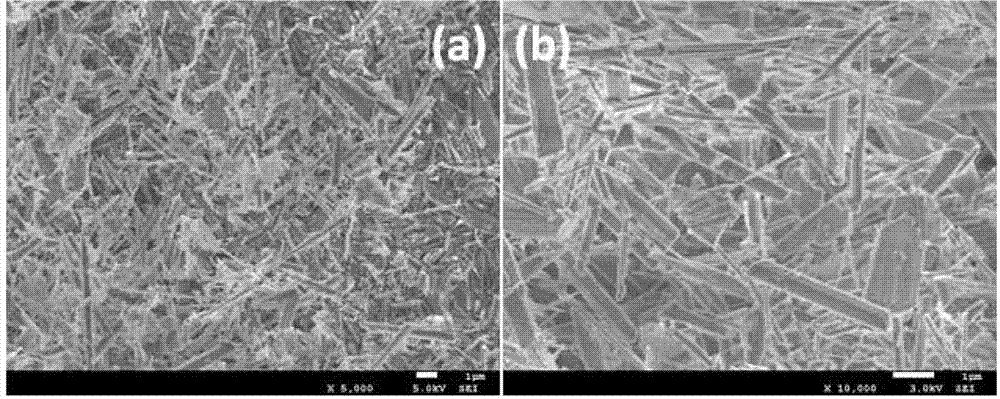

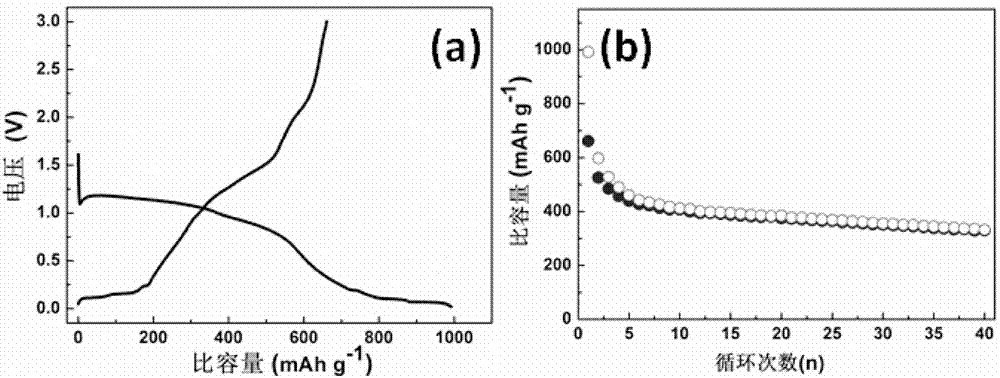

Embodiment 1

[0019] Weigh cobalt acetate, sodium fluoride, and hexamethylenetetramine in a molar ratio of 1:1:5, place in a beaker, add distilled water, stir evenly, transfer to a water heating axe, and react at 120°C for 24 hours. The reaction product was cleaned by centrifugation with alcohol and distilled water, and transferred to a petri dish to dry to obtain a sample. The results show that the prepared samples are located at 20.9°, 32.3°, 33.5°, 34.7°, 35.6°, 38.8°, 39.9°, 43.6°, 51.9°, 52.8°, 56.9°, 59.1° and 61.6° through XRD pattern analysis o The diffraction peaks at the orthorhombic Co(OH)F (110), (310), (201), (400), (111), (211), (410), (311), (221) , (420), (511), (002) and (601) corresponding to crystal planes, consistent with XRD card JCPDS, no. 50-0827. The prepared samples were characterized by SEM, as figure 2 As shown in (a), it consists of a large number of microrods with a length distribution of 1–5 μm. Depend on figure 2 (b) It can be seen that the diameter dis...

Embodiment 2

[0021] Weigh cobalt acetate, sodium fluoride and glucose in a molar ratio of 1:1;1, place in a beaker, add distilled water and stir evenly, transfer to a hot water ax and react at 120°C for 24 hours, centrifuge the reaction product with alcohol and distilled water Wash and transfer to a petri dish to dry the obtained samples. Shown by XRD pattern analysis, such as Figure 4 As shown, the main component of the obtained sample is still orthorhombic Co(OH)F (JCPDS, no. 50-0827), and the diffraction peaks at 23° and 46.7° indicate that the prepared sample contains a small amount of cobalt carbon oxides Impurities. The prepared samples were characterized by SEM, as Figure 5 As shown in (a), it consists of a large number of irregular particles. Depend on Figure 5 (b) It can be seen that the average size of the particles is about 500 nm.

Embodiment 3

[0023] Weigh cobalt acetate and sodium fluoride at a ratio of 1:1, place in a beaker and add distilled water to stir evenly, transfer to a hydrothermal ax and react at 120°C for 24 hours, wash the reaction product with alcohol and distilled water, and transfer to a petri dish The samples were obtained by drying in medium. Shown by XRD pattern analysis, such as Figure 6 As shown, the obtained sample is NaCoF 4 and NaCoF 3 mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com